With its various advantages,3D printing offers many opportunities for businesses to move away from typical production processes and become more efficient. But this is not without its challenges. Indeed, the 3D printing process can sometimes be complex. Many attempts have failed due to various printing errors such as distortions or ghosting. These phenomena can harm the quality of 3D printed parts and sometimes even their performance.

One of these phenomena is the formation of moisture in the filaments, which occurs in particular inin PA, TPU, PVA, PMMU or BVOH filaments, but also in PLA, PETG, nylon or ABS. In fact, during storage, the filament can absorb moisture from the atmosphere in a short time and remain in the material, posing possible future challenges. We explain how to detect humidity and dry your supplies to avoid these printing errors and improve print quality.

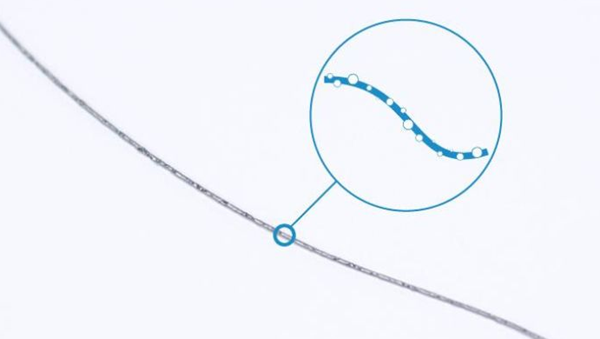

Moisture trapped in the filaments (Photo credit:BCN3D)

Do printing supplies need to be dried?

In most cases you can detect under certain characteristicsHumidity in 3D printing filaments. Perhaps the most obvious is the formation of water beads on the surface of the wire. But most of the time it looks like a complete filament, and moisture is only detectable during the printing process. This can result in under-extrusion, surface defects, filament breakage, extruder clogging, poor adhesion between different layers, and an overall fragile object.

If the surface of the material is not smooth and bubbles form from heat, the yarn should be dried. If your nozzle makes a whistling sound when printing or your machine emits white smoke, drying is also necessary. Overall, most of the time this question can only be answered during the printing process.

measures taken

Now that you’ve determined that residual moisture in the filament is causing printing errors, there are a few things to consider if you want to dry out your filament. One option is to wire thePlace in a preheated domestic oven over low heat for a few hours. For example, to dry the filament, we recommendThe temperature of PLA is 40-45 degrees, and that of ABS and nylon is 80 degrees. Be careful, excessive temperatures can damage your materials.

Another possibility is to put the material in a food dehydrator. This preserves food by drying it using a constant flow of air. The advantage of this device compared to an oven is that it maintains the desired temperature better. If you wish to dry your filament, be sure to find out beforehand what temperature the spool on which the filament is located is suitable.

Equipment dedicated to drying filaments (photo source:Dry repair)

A more professional approach is to use a filament dryer that breaks the intermolecular bonds between water and polymer at the appropriate drying temperature. The device will wireMoisture from the outside is transported to the surrounding air, thereby drying the material. These devices are in fact equipped with adsorption units that absorb the moisture present in the filaments, thus generating very dry air inside the device, allowing the filaments to dry particularly quickly and efficiently. There are different models in the market such asBCN3D model. To use it, simply select the desired setting and the device begins a drying process that lasts several hours.

How to keep wires dry

To avoid drying the threadyou need to make sure you store it properly. There is indeed a problem with some filaments: despite the drying process, due to their high absorbency, moisture can no longer be removed, like nylon.The situation is the same for (PA). This makes the filament very brittle after drying. Generally speaking, wires should be stored away from water and UV rays. It is recommended that the wirePlace in a suitable storage box with a desiccant. A fewThe 3D printer is also equipped with a filament storage unit, which is a fairly practical tool because it allows material to be fed directly into the machine without having to handle spools. Whatever the solution chosen, good storage will avoid going through the drying phase and will thus guarantee better results.

source:3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.