If you’re wondering How To Design A CNC Machine?, you’re stepping into a world where precision engineering, material science, and digital control converge to create tools that power modern manufacturing. Whether you’re a small workshop looking to build a custom machine for niche parts, an R&D team developing a next-generation machining solution, or an enterprise scaling production capabilities, designing a CNC machine requires a holistic approach that balances performance, durability, and cost-effectiveness. In this guide, we’ll break down the core steps to design a CNC machine, highlight critical considerations often overlooked, and explain how partnering with a seasoned precision machining expert like GreatLight CNC Machining Factory can turn your design vision into a functional, reliable tool.

How To Design A CNC Machine? – Core Principles to Guide Your Journey

Designing a CNC machine is not just about assembling parts; it’s about creating a system where every component works in harmony to deliver consistent, high-precision results. Let’s walk through the key phases of the design process, with insights drawn from real-world machining experience to help you avoid common pitfalls.

Defining Clear Functional Requirements First

Before you start drafting blueprints, you need to answer fundamental questions that will shape every aspect of your design:

What parts will the machine produce? Are you machining small, intricate medical components that require ±0.001mm precision, or large aerospace structures up to 4000mm in size? This dictates the machine’s work envelope, spindle power, and axis configuration.

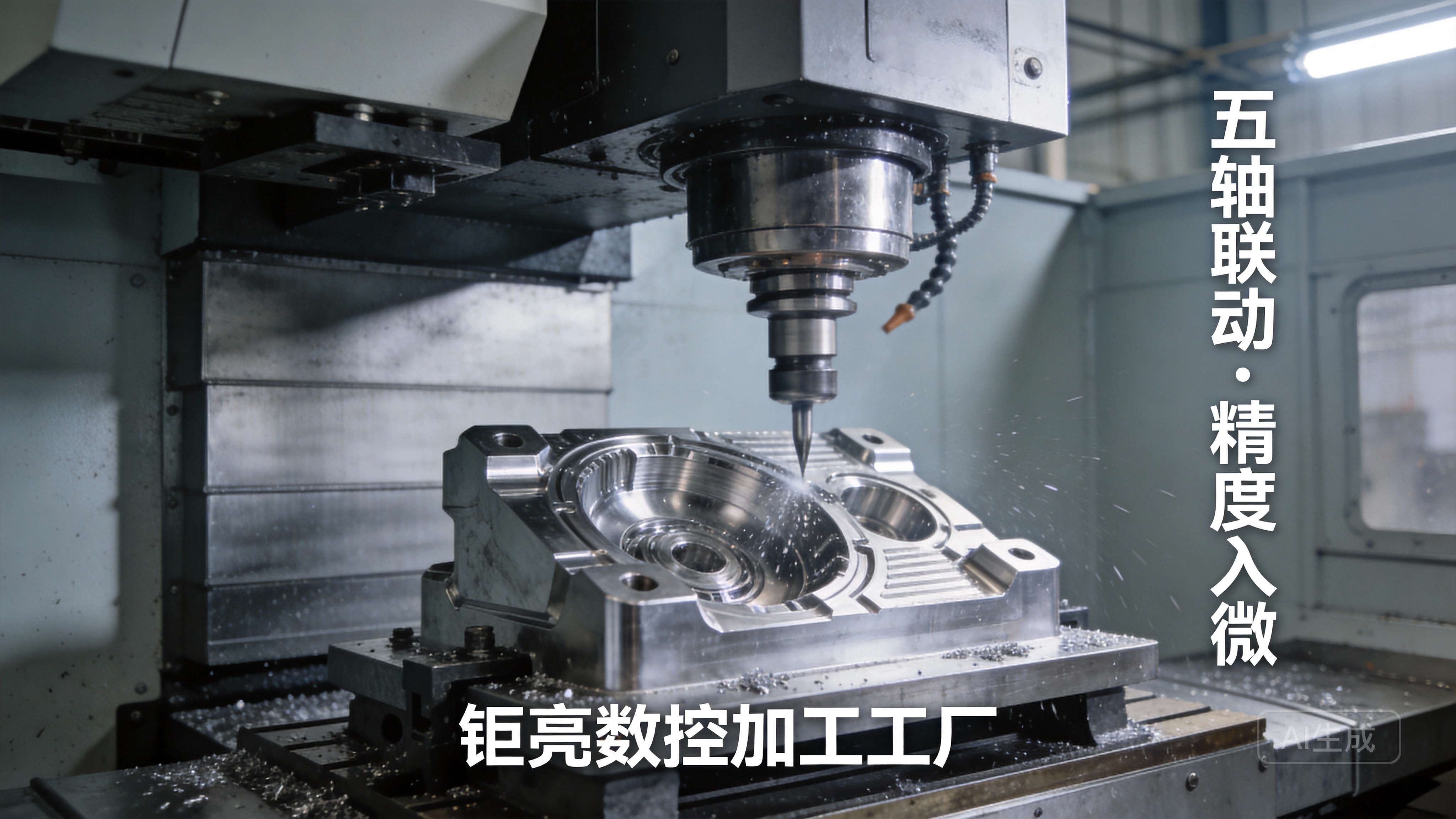

Axis configuration needs: Will a 3-axis machine suffice for simple prismatic parts, or do you need 4-axis or 5-axis capabilities to handle complex geometries like those found in humanoid robot joints or automotive engine components? For reference, GreatLight CNC Machining Factory specializes in five-axis CNC machining (open in new window), leveraging these machines to solve manufacturing challenges for clients across high-end industries.

Material compatibility: Will the machine cut soft plastics, hard stainless steel, or exotic materials like titanium alloy? This influences spindle speed, tool holder design, and coolant system requirements.

Production volume: Is this a prototype machine for low-volume custom parts, or a high-throughput system for mass production? This affects component selection (e.g., servo motors for high-speed, continuous operation vs. stepper motors for low-volume use).

Taking the time to define these requirements is critical—much like how GreatLight’s engineering team collaborates with clients to map out their part specifications before selecting the right machining process. Skipping this step can lead to a machine that either over-delivers (wasting cost) or underperforms (failing to meet production needs).

Selecting Core Components for Reliability and Precision

The quality of your CNC machine’s core components directly impacts its precision, durability, and lifespan. Here are the key components to prioritize:

Spindle: The spindle is the heart of the machine, responsible for rotating the cutting tool. For high-precision applications, choose a spindle with low runout (≤0.002mm) and variable speed capabilities. GreatLight’s 5-axis machining centers feature high-performance spindles that allow them to achieve the tight ±0.001mm precision their clients demand.

Linear guides and ball screws: These components determine the smoothness and accuracy of axis movement. Selecting high-quality linear guides (e.g., HIWIN, THK) and preloaded ball screws minimizes backlash and ensures consistent positioning over thousands of hours of operation. GreatLight relies on these premium components in their in-house machines to maintain precision even during long production runs.

Motors and drives: Stepper motors are cost-effective for low-precision, low-speed applications, while servo motors are ideal for high-speed, high-precision tasks. Closed-loop servo systems with feedback sensors help compensate for errors, a feature GreatLight uses to maintain precision in their 4-axis and 5-axis machining operations.

Tool changer: For automated production, an automatic tool changer (ATC) reduces downtime between operations. The number of tool stations should align with the complexity of the parts you’re machining—GreatLight’s machines are equipped with ATC systems that support up to 40 tools, enabling uninterrupted production of complex components.

Designing the Mechanical Structure for Stability and Durability

A CNC machine’s frame is its foundation; a weak or poorly designed frame will lead to vibration, which ruins precision and shortens tool life. Here’s what to consider:

Frame material: Cast iron frames offer superior vibration damping and thermal stability, making them ideal for high-precision machines. Welded steel frames are more cost-effective but require additional vibration damping measures. GreatLight’s large-scale machining machines use heavy-duty cast iron frames to handle parts up to 4000mm in size without compromising precision.

Vibration damping: Even the best frame will generate vibration during machining. Integrate features like ribbed structures, counterweights, or vibration-isolating mounts to minimize resonance. GreatLight’s engineering team regularly addresses vibration challenges for clients, using their expertise to optimize part designs and machine setups to reduce tool wear and improve surface finish.

Thermal management: Temperature changes can cause frame expansion or contraction, leading to machining errors. Design coolant systems to maintain consistent temperatures, and consider using materials with low thermal expansion coefficients. GreatLight’s ISO 9001:2015 certified processes include strict temperature control measures in their production facilities to ensure part accuracy.

Integrating the Control System – The Brain of the CNC Machine

The control system is what turns digital designs into physical parts. When selecting and integrating a CNC controller:

Choose a reliable controller brand: Leading brands like Fanuc, Siemens, and Haas offer robust software and hardware with extensive support. GreatLight uses a mix of these controllers across their 127 precision machines, allowing their programmers to adapt to client-specific part requirements quickly.

Programming software compatibility: Ensure the controller works with CAD/CAM software like SolidWorks, Mastercam, or CATIA. GreatLight’s in-house team of programmers is proficient in these tools, enabling them to translate complex 3D designs into precise machining paths for 5-axis parts.

Safety features: Integrate emergency stop buttons, door interlocks, and overload protection to comply with industry safety standards. GreatLight adheres to strict safety protocols in their manufacturing facilities, which align with international certifications like IATF 16949 for automotive parts production.

Prototype Testing, Validation, and Iteration

No design is perfect on the first try. Testing and validation are critical to ensuring your CNC machine meets performance standards:

Bench testing: Test individual components (e.g., spindle speed, axis movement) to verify they meet specifications. GreatLight’s rapid prototyping services can help you produce custom components for testing in days, accelerating this phase.

Cutting trials: Run the machine with real parts to measure precision, surface finish, and cycle time. Use precision measurement tools like CMMs (Coordinate Measuring Machines) to validate results—GreatLight has in-house CMMs to ensure every part meets client specifications, with a free rework policy for quality issues and a full refund if rework is unsatisfactory.

Error compensation: Adjust for mechanical errors (e.g., backlash, thermal expansion) using software calibration. GreatLight’s engineers are experts in error compensation, which is key to maintaining their ±0.001mm precision capabilities.

Why Partnering with a Precision Machining Expert Elevates Your CNC Machine Design

Designing a CNC machine in a vacuum can lead to costly oversights. Partnering with a manufacturer that uses CNC machines daily to produce high-precision parts provides you with real-world insights that academic or theoretical design often misses. GreatLight CNC Machining Factory, founded in 2011 in Dongguan’s Chang’an District (China’s “Hardware and Mould Capital”), is a leading expert in this field. Here’s how they can add value to your design process:

Deep expertise in real-world machining: With over 10 years of experience producing parts for automotive engines, humanoid robots, medical devices, and aerospace, GreatLight’s team knows exactly what CNC machines need to perform under demanding conditions. For example, when working with a new energy vehicle client to develop an e-housing, GreatLight optimized the machine setup to handle the large, thin-walled part without warping—a challenge that required adjusting spindle speed and coolant flow, insights that can inform your own CNC machine design.

Access to a full-process chain: GreatLight offers nearly 100 rapid prototyping and machining services, including 3D printing (stainless steel, aluminum alloy, titanium alloy), die casting, sheet metal fabrication, and one-stop surface post-processing. This means you can prototype custom machine components quickly and iterate on your design without relying on multiple suppliers.

International certifications for quality assurance: GreatLight holds ISO 9001:2015, IATF 16949 (automotive), ISO 13485 (medical), and ISO 27001 (data security) certifications. These certifications ensure that their manufacturing processes adhere to global standards, which can guide your own design to meet industry-specific requirements.

Scalable production support: Once your CNC machine design is finalized, GreatLight can help you produce components in volume, thanks to their three wholly-owned manufacturing plants and 150-person team. Their after-sales guarantee provides peace of mind, with free rework for quality issues and a full refund if rework doesn’t meet your expectations.

Common Pitfalls to Avoid When Designing a CNC Machine

Even experienced designers can make mistakes that compromise machine performance. Here are three key pitfalls to watch out for:

Ignoring vibration damping: Many new designers focus on precision components but overlook frame stability. Vibration can lead to tool breakage, poor surface finish, and reduced machine lifespan. GreatLight’s experience with large parts (up to 4000mm) has taught them that investing in a robust, vibration-damped frame is non-negotiable for consistent performance.

Cutting corners on component quality: While cost savings are important, using low-quality linear guides or motors will lead to frequent breakdowns and reduced precision over time. GreatLight uses only premium components in their machines, which is why they can achieve ±0.001mm precision and offer a reliable after-sales guarantee.

Skipping user-centric design: The machine should be easy to operate, maintain, and repair. GreatLight’s machines are designed with user-friendliness in mind, which reduces operator error and downtime—something you should prioritize in your own design.

Conclusion

If you’ve been asking How To Design A CNC Machine?, you now know that it’s a multi-phase process that requires careful planning, attention to detail, and real-world machining expertise. From defining functional requirements to testing and validating prototypes, every step plays a critical role in creating a machine that meets your production needs. Partnering with a trusted precision machining expert like GreatLight CNC Machining Factory can provide you with the insights, support, and resources to turn your design vision into a reliable, high-performance tool. For more information on how GreatLight’s industry leadership can support your CNC machine design journey, visit their LinkedIn page (open in new window).

Frequently Asked Questions (FAQ)

Q: What is the most critical factor in CNC machine design for high-precision applications?

A: The most critical factor is the combination of a vibration-damped mechanical frame, high-quality core components (spindle, linear guides, ball screws), and a precise control system with error compensation. GreatLight CNC Machining Factory leverages this combination to achieve ±0.001mm precision in their own machining operations, which is essential for producing complex parts in medical and aerospace industries.

Q: Can I design a custom CNC machine for niche applications without extensive engineering experience?

A: While it’s possible, partnering with a precision machining expert like GreatLight can significantly reduce risks and save time. GreatLight’s team can help you define functional requirements, select appropriate components, and validate your design with real-world cutting trials. Their rapid prototyping services also allow you to test custom components quickly, without committing to full-scale production.

Q: How long does it typically take to design and build a custom CNC machine?

A: The timeline depends on the machine’s complexity. A simple 3-axis machine can take 3-6 months from design to final testing, while a custom 5-axis machine with specialized features can take 6-12 months. GreatLight’s rapid prototyping services can accelerate the component testing phase, reducing overall design time by up to 30% in some cases.

Q: What certifications should my CNC machine design comply with for industry-specific use?

A: For automotive parts production, your machine should align with IATF 16949 standards. For medical devices, ISO 13485 is critical. GreatLight CNC Machining Factory holds both certifications, so their team can guide your design to meet these strict requirements. Additionally, ISO 9001:2015 is a foundational certification that ensures consistent quality across all manufacturing processes.

Q: How can I ensure my CNC machine design is cost-effective without sacrificing performance?

A: Focus on prioritizing components that directly impact your key requirements. For example, if you’re machining soft plastics, you may not need a high-power spindle, but you should invest in precise linear guides for tight tolerances. GreatLight’s engineers specialize in balancing cost and performance for client projects, so they can provide insights into where to allocate your budget for maximum impact.