Mastering Precision: How GreatLight Metal Tech Co., LTD. Elevates CNC Machining Control for High-End Hardware Innovation

In the era of Industry 4.0, CNC machining has evolved from a traditional manufacturing process into a cornerstone of intelligent production. For R&D teams, hardware startups, and engineers, the challenge lies not just in operating CNC machines but in achieving consistent, ultra-high precision that bridges the gap between design concepts and mass-produced parts.

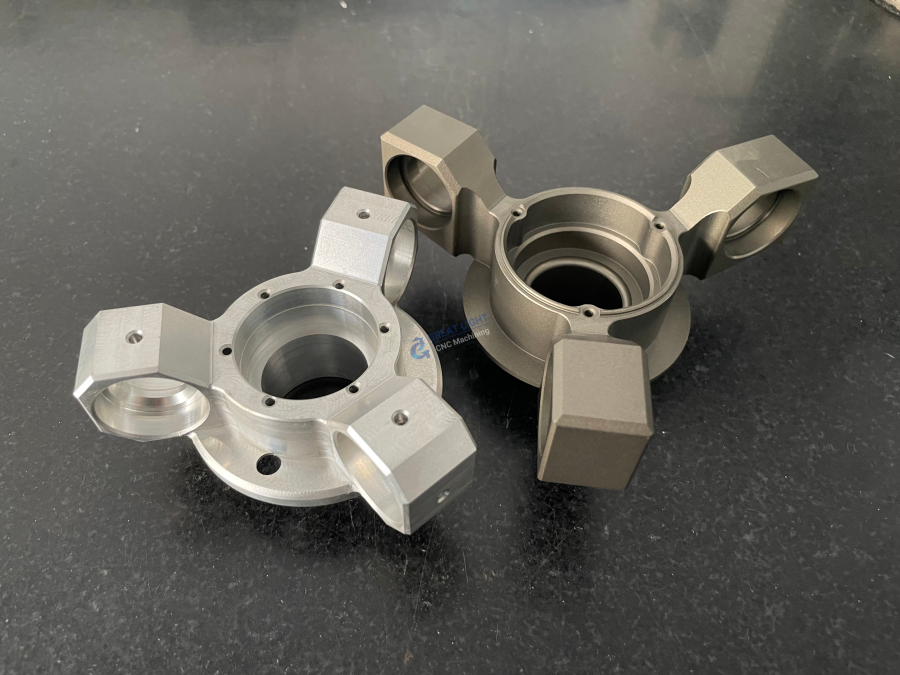

This article explores how GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal), a leader in precision part manufacturing, leverages advanced equipment, rigorous quality systems, and deep engineering expertise to redefine CNC machining control—delivering parts with tolerances as tight as ±0.001mm while addressing seven critical pain points in the industry.

The Core of CNC Control: From Hardware to Process Mastery

1. Advanced Equipment: The Foundation of Precision

Multi-Axis Machining Centers: GreatLight Metal’s 127+ precision machines include 5-axis CNC systems from DMG Mori and Beijing Jingdiao, enabling simultaneous machining of complex geometries with minimal setups. Unlike 3-axis machines, 5-axis systems eliminate repositioning errors, achieving ±0.001mm accuracy even for parts with intricate curves or deep cavities.

Complementary Technologies: To support CNC machining, GreatLight integrates EDM (Electrical Discharge Machining) for hardened materials, 5-axis laser cutting for thin-walled components, and ultrasonic machining for brittle materials like ceramics. This ecosystem ensures no design is “unmachinable.”

2. Process Optimization: Turning Data into Precision

Digital Twin Simulation: Before cutting metal, GreatLight uses CAM software to simulate tool paths, detecting collisions or material stress points. This reduces trial runs and ensures first-article success.

Adaptive Machining: Real-time monitoring adjusts cutting parameters (e.g., spindle speed, feed rate) based on material feedback, maintaining precision even during long runs. For example, machining aerospace titanium alloys requires dynamic adjustments to avoid tool wear-induced errors.

Tooling Strategy: GreatLight’s engineers select micro-grain carbide tools with specialized coatings (e.g., TiAlN) for high-speed machining, balancing tool life and surface finish. For ultra-fine features (<0.1mm), they employ pico-second lasers or wire EDM.

Overcoming Industry Pain Points Through Systematic Control

Pain Point 1: The “Precision Black Hole” – Inconsistent Tolerances

GreatLight’s Solution:

ISO 9001:2015-Certified Workflows: Every part undergoes in-process inspection using CMM (Coordinate Measuring Machines) and laser scanners. Data is logged for traceability.

Closed-Loop Feedback: Machines auto-correct deviations based on inspection results, ensuring batch consistency. For instance, a medical implant batch of 10,000 parts maintained ±0.002mm tolerance across all items.

Pain Point 2: Complex Geometries = High Scrap Rates

GreatLight’s Solution:

5-Axis Simultaneous Machining: Reduces setups from 5+ (on 3-axis machines) to just 1, minimizing human error. A humanoid robot joint with 17° angled features was machined in one cycle, cutting lead time by 60%.

Hybrid Manufacturing: Combines CNC with 3D printing (SLM/SLA) for near-net-shape parts, reducing machining volume and distortion risks.

Pain Point 3: Slow Prototyping-to-Production Transition

GreatLight’s Solution:

Rapid Tooling: Uses soft jaws and modular fixtures to adapt existing workholding for new parts, slashing setup time. A new energy vehicle (NEV) e-housing prototype was ready in 3 days vs. the industry average of 2 weeks.

Scalable Processes: The same CAM programs and tooling strategies are used for prototypes and mass production, ensuring design intent is preserved at scale.

Why GreatLight Metal Stands Out: Certifications That Matter

GreatLight’s commitment to control extends beyond equipment—it’s embedded in global certifications:

ISO 9001:2015: Guarantees quality management at every stage, from material intake to final inspection.

ISO 13485: For medical hardware, ensuring compliance with stringent regulatory requirements (e.g., biocompatibility, cleanroom machining).

IATF 16949: Automotive-grade precision, with processes designed to eliminate defects in safety-critical parts like engine blocks or transmission components.

These certifications are not just badges; they’re frameworks that standardize precision control, making GreatLight a trusted partner for brands like BYD (automotive) and Mindray (medical devices).

Case Study: Machining a Humanoid Robot’s “Heart”

A leading robotics firm needed a high-precision gearbox for a humanoid robot’s knee joint. The challenges:

Tight tolerances: ±0.005mm on gear teeth profiles.

Material: Hardened stainless steel (HRC 52), prone to tool wear.

Complexity: 12 angled holes and internal splines requiring 5-axis access.

GreatLight’s Approach:

Pre-Machining Simulation: Identified optimal tool paths to avoid collisions.

Tool Selection: Used CBN (Cubic Boron Nitride) inserts for high-speed turning of hardened steel.

In-Process Inspection: A robotic arm loaded parts into a CMM for real-time feedback, adjusting feeds if deviations exceeded 0.002mm.

Post-Machining: Vapor polishing achieved a mirror finish (Ra < 0.2μm), reducing friction in the joint.

Result: The gearbox survived 10 million cycles in testing, matching the robot’s lifespan target. The client reduced development time by 40% compared to their previous supplier.

Conclusion: Precision Control as a Service

CNC machining control is not just about operating machines—it’s a holistic discipline combining equipment, software, materials science, and quality systems. GreatLight Metal Tech Co., LTD. has mastered this discipline by:

Investing in 5-axis CNC machining and complementary technologies.

Implementing ISO-certified workflows for consistency.

Solving real-world problems for clients in automotive, medical, and robotics sectors.

For R&D teams seeking a partner that turns precision challenges into solutions, GreatLight Metal offers more than machining—it delivers peace of mind. Explore their 5-axis CNC machining services to see how they can control complexity for your next project.

Frequently Asked Questions (FAQs)

Q1: What makes 5-axis CNC better than 3-axis for precision parts?

A: 5-axis machines can rotate the tool or part on two additional axes, enabling single-setup machining of complex geometries. This reduces errors from repositioning and improves surface finish by maintaining optimal tool angles. GreatLight’s 5-axis systems achieve ±0.001mm accuracy even for parts with undercuts or deep cavities.

Q2: How does GreatLight ensure batch-to-batch consistency?

A: Through closed-loop manufacturing:

In-process CMM inspection logs data for every part.

Machines auto-adjust parameters if deviations exceed limits.

Final inspection uses laser scanning to verify tolerances before shipment.

This system helped a medical device client maintain ±0.002mm consistency across 50,000 parts.

Q3: Can GreatLight machine parts from 3D-printed blanks?

A: Yes. GreatLight combines SLM 3D printing (for metal) or SLA/SLS (for plastics) with CNC finishing. This hybrid approach reduces material waste and machining time for complex shapes. For example, a titanium aerospace bracket was 3D-printed to near-net shape, then CNC-finished to ±0.003mm tolerance in 2 hours vs. 8 hours of full machining.

Q4: What industries benefit most from GreatLight’s precision control?

A:

Automotive: Engine components, transmission parts, and electric vehicle (EV) battery housings requiring IATF 16949-certified processes.

Medical: Surgical tools, implants, and diagnostic devices needing ISO 13485 compliance and biocompatible finishes.

Robotics: High-wear joints, gearboxes, and actuators demanding micro-precision and fatigue resistance.

Q5: How does GreatLight protect intellectual property (IP) for sensitive projects?

A: GreatLight adheres to ISO 27001 standards for data security:

All design files are encrypted and stored on private servers.

Employees sign NDAs, and facility access is restricted via biometric scans.

For defense or aerospace clients, dedicated “clean rooms” isolate projects physically and digitally.

For more insights, visit GreatLight Metal’s LinkedIn profile for client testimonials and project showcases.