Unlocking the Power of CNC Machine Tool Data: A Comprehensive Guide to Configuration and Acquisition

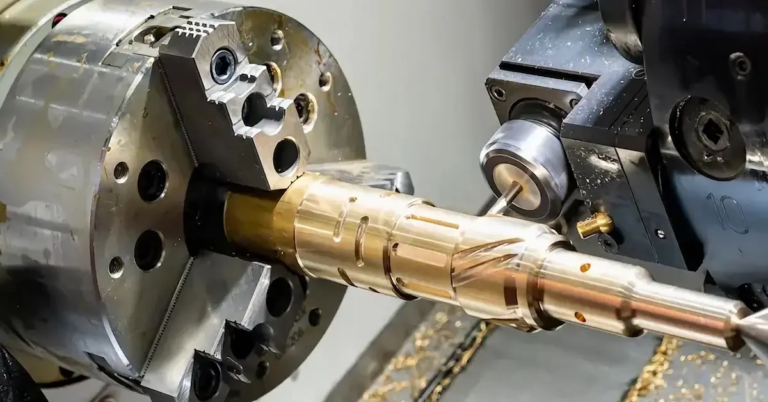

In the world of manufacturing, CNC machine tools play a vital role in producing high-precision parts and components. The data generated by these machines is a treasure trove of information, offering insights into machine performance, productivity, and efficiency. However, acquiring and configuring this data can be a daunting task, especially for those new to the field. In this article, we will delve into the world of CNC machine tool data acquisition, exploring the various methods, protocols, and best practices for unlocking the full potential of this valuable resource.

Understanding CNC Machine Tool Data

CNC machine tools generate a vast amount of data, including:

- Machine status: Real-time information on machine operation, such as speed, feed rate, and spindle load.

- Production data: Information on parts produced, including quantity, quality, and production time.

- Error messages: Alerts and notifications regarding machine errors, alarms, and warnings.

- Maintenance data: Records of maintenance activities, including schedules, performed tasks, and replacement parts.

Configuration Methods for CNC Machine Tool Data Acquisition

There are several methods for configuring CNC machine tool data acquisition, including:

- RS-232/RS-485: A serial communication protocol used for connecting devices, such as computers and CNC machines.

- Ethernet: A networking protocol used for connecting devices, such as CNC machines and servers.

- MTConnect: An open standard for machine tool data exchange, enabling communication between machines and software applications.

- OPC UA: An open standard for industrial communication, enabling data exchange between devices and applications.

- Modbus: A master-slave protocol used for communicating between devices, such as PLCs and CNC machines.

Acquisition Protocols for CNC Machine Tool Data

Once the configuration method is chosen, the next step is to select an acquisition protocol. Some popular protocols include:

- MTConnect adapter: A software application that translates machine tool data into a standardized format.

- OPC UA client: A software application that connects to an OPC UA server, enabling data exchange.

- Modbus master: A software application that communicates with Modbus slaves, such as PLCs and CNC machines.

- HTTP/HTTPS: A protocol used for web-based communication, enabling data exchange between devices and applications.

Best Practices for CNC Machine Tool Data Acquisition

To ensure successful data acquisition, follow these best practices:

- Choose the right configuration method: Select a method that suits your specific needs and equipment.

- Ensure compatibility: Verify that the acquisition protocol is compatible with your CNC machine and software applications.

- Configure data sampling rates: Set the data sampling rate to balance data quality and storage requirements.

- Implement data filtering: Filter out irrelevant data to reduce storage requirements and improve data quality.

- Monitor data quality: Regularly check data quality to ensure accuracy and reliability.

Benefits of CNC Machine Tool Data Acquisition

The benefits of acquiring CNC machine tool data are numerous, including:

- Improved machine performance: Real-time monitoring enables prompt intervention, reducing downtime and increasing productivity.

- Enhanced quality control: Production data analysis enables quality control, reducing defects and improving product quality.

- Predictive maintenance: Maintenance data analysis enables predictive maintenance, reducing downtime and extending machine lifespan.

- Increased efficiency: Data-driven decision making enables optimized production planning, reducing waste and improving efficiency.

- Cost reduction: Reduced downtime, improved quality, and increased efficiency lead to cost savings and increased profitability.

Conclusion

In conclusion, acquiring CNC machine tool data is a powerful way to unlock the full potential of your manufacturing operations. By understanding the various configuration methods, acquisition protocols, and best practices, you can harness the power of this valuable resource. Remember to choose the right configuration method, ensure compatibility, and implement data filtering to ensure successful data acquisition. With the benefits of improved machine performance, enhanced quality control, predictive maintenance, increased efficiency, and cost reduction, CNC machine tool data acquisition is an essential tool for any manufacturing operation.