How To Choose The Best Lubricant For A CNC Machine?

In the realm of precision parts machining and customization, CNC machines are the workhorses that bring intricate designs to life. One crucial aspect that often gets overlooked but is vital for the smooth operation and longevity of these machines is the choice of lubricant. GreatLight CNC Machining Factory, a professional five – axis CNC machining manufacturer, understands the importance of using the right lubricant to ensure optimal performance of its advanced machinery.

Why Lubrication is Essential for CNC Machines

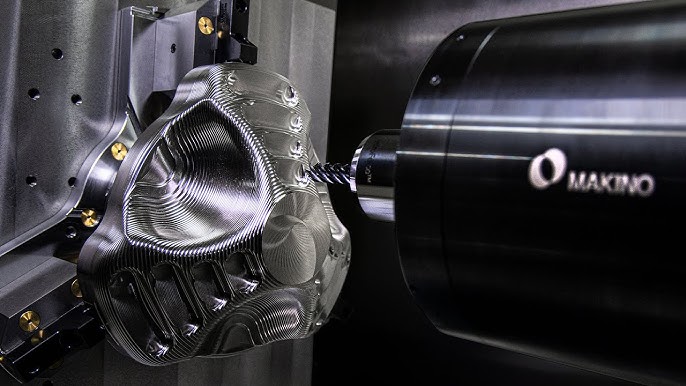

Lubrication serves several key functions in a CNC machine. Firstly, it reduces friction between moving parts. In a CNC machine, there are numerous components such as spindles, axes, and slides that move at high speeds and with great precision. Friction can cause wear and tear on these parts, leading to premature failure and a decrease in machining accuracy. By applying a suitable lubricant, the friction is minimized, which in turn reduces heat generation. Excessive heat can distort the machine’s components and affect the dimensional accuracy of the parts being machined.

Secondly, lubrication helps to remove debris and contaminants from the machine. As the machine operates, it generates small metal chips and dust particles. A good lubricant can carry these particles away from the critical areas of the machine, preventing them from causing damage or interfering with the machining process.

Factors to Consider When Choosing a Lubricant

Machine Type and Application: Different CNC machines have different lubrication requirements. For example, a high – speed spindle in a five – axis CNC machining center may require a lubricant with excellent high – speed performance and anti – wear properties. On the other hand, a linear guideway may need a lubricant that provides good adhesion and corrosion protection. Consider the specific functions and operating conditions of your machine when selecting a lubricant.

Lubricant Type: There are several types of lubricants available, including oils, greases, and synthetic lubricants.

Oils: Oils are commonly used in CNC machines because they can provide continuous lubrication and are easily circulated through the machine’s lubrication system. They are suitable for high – speed applications and can offer good cooling properties. However, they may require more frequent replenishment compared to greases.

Greases: Greases are a mixture of oil and a thickening agent. They are ideal for applications where the lubricant needs to stay in place for a longer time, such as in slow – moving or heavily loaded components. Greases can provide better sealing against contaminants but may not be as effective in high – speed applications as oils.

Synthetic Lubricants: Synthetic lubricants are engineered to offer superior performance compared to traditional oils and greases. They have better thermal stability, oxidation resistance, and anti – wear properties. Although they are generally more expensive, they can provide longer service life and better protection for the machine, especially in demanding applications.

Environmental Factors: The operating environment of the CNC machine can also influence the choice of lubricant. If the machine is located in a dusty or humid environment, a lubricant with good anti – corrosion and anti – contamination properties is essential. In addition, some industries may have specific environmental regulations regarding the use of lubricants, so it is important to choose a lubricant that complies with these regulations.

Compatibility with Machine Materials: The lubricant should be compatible with the materials used in the machine. For example, some lubricants may react with certain metals or plastics, causing corrosion or degradation. Make sure to check the manufacturer’s recommendations regarding the compatibility of the lubricant with the machine’s components.

GreatLight CNC Machining Factory’s Approach to Lubrication

GreatLight CNC Machining Factory, with its advanced five – axis CNC machining equipment and production technology, pays meticulous attention to the lubrication of its machines. The factory has a team of experienced technicians who are well – versed in the lubrication requirements of different machines. They follow strict maintenance schedules to ensure that the machines are properly lubricated at all times.

The factory uses high – quality lubricants that are specifically selected based on the machine type, application, and environmental conditions. By using the right lubricants, GreatLight CNC Machining Factory can maintain the high precision and reliability of its machining operations, which is crucial for providing one – stop post – processing and finishing services to its clients.

Conclusion

Choosing the best lubricant for a CNC machine is a critical decision that can have a significant impact on the machine’s performance, accuracy, and lifespan. By considering factors such as machine type, lubricant type, environmental factors, and material compatibility, you can make an informed choice. GreatLight CNC Machining Factory, with its expertise and commitment to quality, is a reliable partner in the precision parts machining and customization field. Whether you need complex parts manufactured from 3D designs or finished products for high – end conference presentations, the factory can ensure that its CNC machines are operating at their best with the right lubrication.

Frequently Asked Questions (FAQ)

Q: How often should I change the lubricant in my CNC machine?

A: The frequency of lubricant change depends on several factors such as the type of machine, the operating conditions, and the type of lubricant used. Generally, it is recommended to follow the manufacturer’s guidelines. In some cases, it may be necessary to change the lubricant every few months, while in others, it may be possible to extend the interval to a year or more.

Q: Can I use any lubricant in my CNC machine?

A: No, you cannot use just any lubricant. It is important to choose a lubricant that is suitable for the specific requirements of your machine. Using an inappropriate lubricant can cause damage to the machine and affect its performance. Always refer to the machine’s manual or consult with the manufacturer for the recommended lubricants.

Q: What are the signs that my CNC machine needs more lubricant?

A: Some signs that your machine may need more lubricant include increased noise during operation, higher operating temperatures, decreased machining accuracy, and visible wear on the moving parts. If you notice any of these signs, it is advisable to check the lubricant level and condition and add or replace the lubricant as needed.

Q: Are synthetic lubricants worth the extra cost?

A: Synthetic lubricants are generally more expensive than traditional oils and greases, but they offer several advantages. They have better thermal stability, oxidation resistance, and anti – wear properties, which can lead to longer service life and better protection for the machine. In demanding applications or for machines with high – precision requirements, the benefits of synthetic lubricants often outweigh the additional cost. GreatLight CNC Machining Factory can provide more insights on the cost – benefit analysis based on your specific needs. For more information about GreatLight CNC Machining Factory, you can visit their LinkedIn page.