As a senior manufacturing engineer who has spent decades navigating the intricate landscape of precision part production, I am often approached with one fundamental question that sits at the heart of every project’s feasibility: “How to calculate machining cost for CNC machines?” This is not merely a question about arithmetic; it is a query that delves into the very essence of manufacturing economics, supply chain transparency, and value creation. A clear understanding of this process empowers you, the client, to make informed decisions, optimize designs for manufacturability (DFM), and build a more collaborative and cost-effective partnership with your machining supplier.

Contrary to a simple formula, calculating CNC machining cost is an exercise in multi-variable analysis. It involves dissecting a part’s journey from raw material to finished component, assigning tangible and intangible costs at each stage. Let’s demystify this process.

H2: The Core Components of a CNC Machining Cost Breakdown

Every quotation you receive is built upon several foundational pillars. Understanding these pillars is the first step toward mastering cost calculation.

H3: 1. Raw Material Costs

This is often the most straightforward variable but has significant nuances.

Material Type: The cost per kilogram or cubic inch varies drastically—from common aluminum alloys (e.g., 6061, 7075) and stainless steels (e.g., 304, 316) to exotic materials like titanium (Ti6Al4V), Inconel, or PEEK plastic.

Material Form & Size: Costs differ between round bars, rectangular blocks, plates, or tubes. You pay for the entire billet purchased, not just the final part volume. A crucial aspect of Design for Manufacturability (DFM) is choosing a standard stock size to minimize waste (scrap).

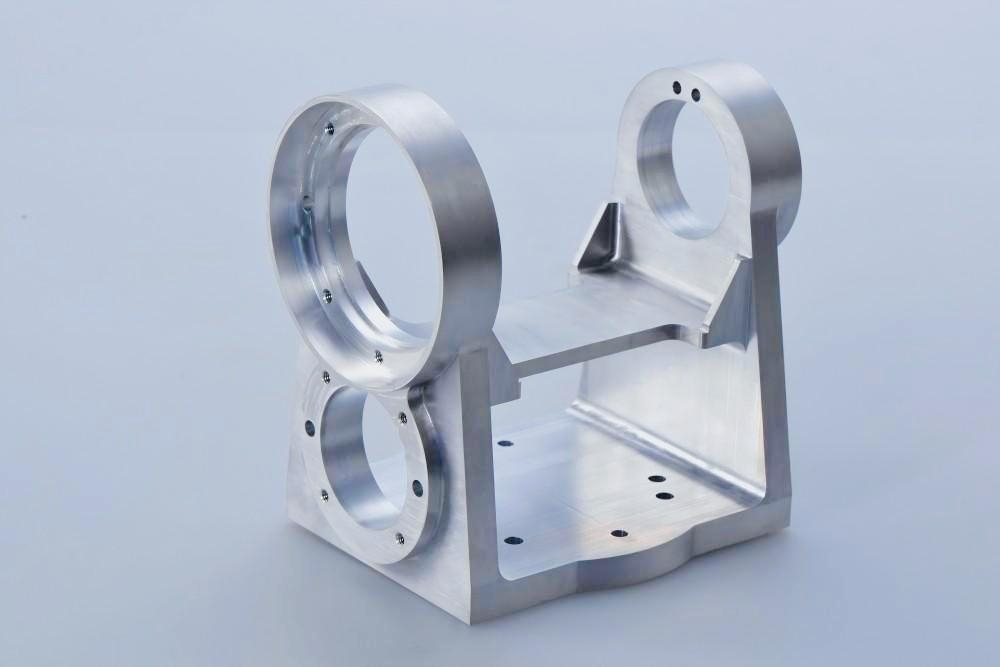

Material Waste: The machining process generates chips. The cost of this wasted material is factored into the price. Complex parts with high buy-to-fly ratios (where a large block is carved down to a small, intricate part) inherently have higher material cost components.

H3: 2. Machine Time & Operation Costs (The Heart of the Calculation)

This is where engineering expertise directly translates to cost. It’s calculated as:

Machine Time (Hours) x Machine Hourly Rate (MHR)

Machine Hourly Rate (MHR): This is not just electricity. It’s a comprehensive rate that amortizes the capital investment in the machine, floor space, maintenance, tooling libraries, and the indirect labor of programmers and setup technicians. A standard 3-axis mill has a lower MHR than a high-end 5-axis CNC machining center due to the latter’s complexity and capability.

Calculating Machine Time: This requires detailed CNC programming simulation. Factors include:

Setup Time: The time to fixture the raw material, load tools, and run first-article inspection. For low-volume prototypes, setup can be a dominant cost. For mass production, it’s amortized over many parts.

Cutting Time: Determined by the toolpaths, cutting speeds, feed rates, depth of cut, and the required number of operations (roughing, semi-finishing, finishing).

Complexity: A part requiring 5-axis CNC machining services to access complex geometries in a single setup will have different time economics than a part needing multiple re-fixturings on a 3-axis machine. While 5-axis MHR is higher, it often reduces total machine time and improves accuracy for complex parts.

H3: 3. Labor & Engineering Costs

Programming & CAM Work: Translating your 3D CAD model into efficient, error-free machine code requires skilled engineers. Highly complex parts demand more programming time.

Setup & Operation: While increasingly automated, skilled technicians are needed to oversee the process.

Quality Assurance & Inspection: Time spent on First Article Inspection (FAI), in-process checks, and final validation using tools like CMMs (Coordinate Measuring Machines) is a critical cost. Suppliers with robust in-house metrology, like GreatLight Metal, factor this into their process to ensure compliance with tight tolerances (e.g., ±0.001mm).

H3: 4. Tooling & Consumables

Cutting tools (end mills, drills, inserts) wear out. The cost of tool wear, especially when machining hard materials like hardened steel or using small, fragile tools for fine details, is calculated and included. Specialized tooling may be required.

H3: 5. Surface Finishing & Post-Processing

Very few parts come off the machine ready for use. Additional costs apply for:

Deburring: Manually or tumbling to remove sharp edges.

Surface Treatments: Anodizing, plating, powder coating, passivation, heat treatment. Each adds process time and material cost.

Special Finishes: Polishing to a mirror finish or applying textures.

H3: 6. Overhead & Administrative Costs

This covers the cost of running the business: management, sales, utilities, facility maintenance, and crucially, compliance with certifications. A manufacturer maintaining ISO 9001:2015 for quality management and IATF 16949 for automotive standards inherently has systematic overhead costs that ensure traceability, consistency, and risk mitigation—value that often outweighs the nominal cost difference.

H3: 7. Profit Margin

A sustainable supplier must include a reasonable profit margin to reinvest in new technology, training, and continuous improvement, ensuring they remain a reliable partner for your future projects.

H2: A Practical Framework: How to Estimate Your Project’s Cost

While an exact quote requires a detailed DFM analysis with your chosen supplier, you can create a ballpark estimate:

Define the Part: Solid model, material, quantity, critical tolerances (±0.1mm vs. ±0.01mm), and surface finish requirements.

Estimate Material Volume: Calculate the volume of the final part and add a significant percentage (often 20-50%) for waste/scrap and fixturing.

Assess Complexity: How many setups? Does it require 3-axis, 4-axis, or 5-axis CNC machining services? Are there deep pockets, thin walls, or undercuts?

Request a Detailed Quote: Provide the above information to 2-3 reputable suppliers. A high-quality quote will break down costs per the components listed above, not just give a single number.

H2: The GreatLight Metal Approach: Transparency and Value Engineering

At GreatLight Metal Tech Co., LTD., we view cost calculation as the starting point for a collaborative conversation on value engineering. Our process is designed for clarity:

Comprehensive DFM Feedback: Upon receiving your design, our engineering team doesn’t just calculate cost; we proactively suggest modifications that could reduce machining time or material waste without compromising function.

Process Integration Advantage: As a provider of integrated manufacturing solutions, we can often consolidate processes. For instance, a part might be optimally produced using a combination of 5-axis CNC machining for critical features and metal 3D printing (SLM) for complex internal channels, which we can manage seamlessly in-house, avoiding multiple vendor markups and logistics.

Certification-Backed Consistency: Our ISO 9001, IATF 16949, and ISO 13485 frameworks mean our cost estimates are built on standardized, repeatable processes. There are no hidden “quality gamble” discounts; the price reflects a guaranteed outcome, reducing the risk of costly delays or field failures.

H2: Conclusion: Cost vs. Total Cost of Ownership

Ultimately, learning how to calculate machining cost for CNC machines teaches us that the cheapest initial quote can be the most expensive in the long run. The “Total Cost of Ownership” includes:

Quality Failures: Scrap parts, delayed assemblies, warranty claims.

Communication Overhead: Time spent clarifying issues with an inexperienced supplier.

Supply Chain Risk: Instability of a supplier focused only on low price.

Choosing a partner like GreatLight Metal means investing in a cost structure built on precision equipment, authoritative certifications, and deep engineering support. This partnership minimizes total lifecycle cost by delivering right-first-time quality, on-time reliability, and innovation-focused collaboration. The most accurate cost calculation is one that factors in not just the price of making a part, but the value of a trouble-free pathway from your design to a perfected, functional component in your hands.

H2: Frequently Asked Questions (FAQ)

Q1: What is the single biggest factor that drives up CNC machining costs?

A: Part complexity and tight tolerances. A design requiring multiple setups, specialized 5-axis machining, or tolerances below ±0.025mm (±0.001″) exponentially increases programming time, machine time, inspection time, and the risk of scrap. Simplifying designs and specifying tolerances only where truly critical is the most effective way to control costs.

Q2: Why does a prototype of one part sometimes cost nearly as much as a small batch of 10?

A: The primary cost drivers for a single prototype are non-recurring engineering (NRE) costs: CAD/CAM programming, custom fixture design/manufacture, and First Article Inspection. These are one-time costs. In a batch of 10, the NRE cost is amortized over all units, so the per-part cost decreases significantly, with the main addition being raw material and incremental machine time.

Q3: How do certifications like ISO 9001 affect the price quote?

A: They add a mandatory layer of process rigor, documentation, and quality checks, which incurs overhead. However, this translates to reduced risk and higher predictability for you. You are paying for a system that ensures consistency, traceability, and continuous improvement, which prevents expensive errors and rework down the line.

Q4: Can I provide my own material to save costs?

A: Sometimes, but it’s often not advised. Reputable manufacturers like GreatLight Metal have trusted supply chains that guarantee material certification (e.g., Mill Certificates), proper storage, and handling. Providing your own material transfers the risk of material defects to you and may incur additional handling and verification fees. It’s best to discuss this option transparently with your supplier.

Q5: How does in-house post-processing affect the overall cost and timeline?

A: It significantly reduces both. Integrating post-processing (like anodizing or heat treatment) under one roof, as we do at GreatLight Metal, eliminates separate vendor logistics, communication gaps, and additional profit margins. It streamlines scheduling, improves quality control, and typically results in a lower total cost and faster turnaround than managing multiple subcontractors yourself. For more insights into industry practices and partnerships, you can explore professional networks like those found on LinkedIn{:target=”_blank”}.