Precision Machining Redefined: Why GreatLight CNC Machining Factory is Your Ideal Partner for High-End Custom Parts

In the era of Industry 4.0, precision CNC machining has evolved from a niche manufacturing process into a cornerstone of innovation across industries like aerospace, automotive, medical devices, and robotics. However, not all CNC machining providers are created equal. For businesses seeking high-precision, reliable, and scalable custom part manufacturing, the choice of partner can mean the difference between success and costly setbacks.

GreatLight CNC Machining Factory—a leader in five-axis CNC machining and integrated manufacturing solutions—stands out by addressing the most critical pain points in precision machining: tolerance consistency, material versatility, process scalability, and post-processing integration.

This article explores why GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) is the preferred choice for global clients demanding ultra-high precision (±0.001mm), rapid prototyping, and mass production of complex metal and plastic parts.

The Core Challenge: Why Traditional CNC Machining Falls Short

Many manufacturers claim to offer “high-precision” CNC services, but the reality often falls short due to:

Outdated equipment: Older 3-axis or 4-axis machines struggle with complex geometries.

Inconsistent processes: Lack of standardized workflows leads to tolerance variations.

Limited material expertise: Not all suppliers can handle exotic alloys or engineering plastics.

Fragmented services: Prototyping and production may involve multiple vendors, increasing lead times and risks.

GreatLight Metal addresses these issues head-on with advanced technology, rigorous quality control, and a full-process chain—from design to finishing.

Why GreatLight Metal Stands Out: Four Pillars of Competitive Advantage

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates 127 pieces of precision machinery, including:

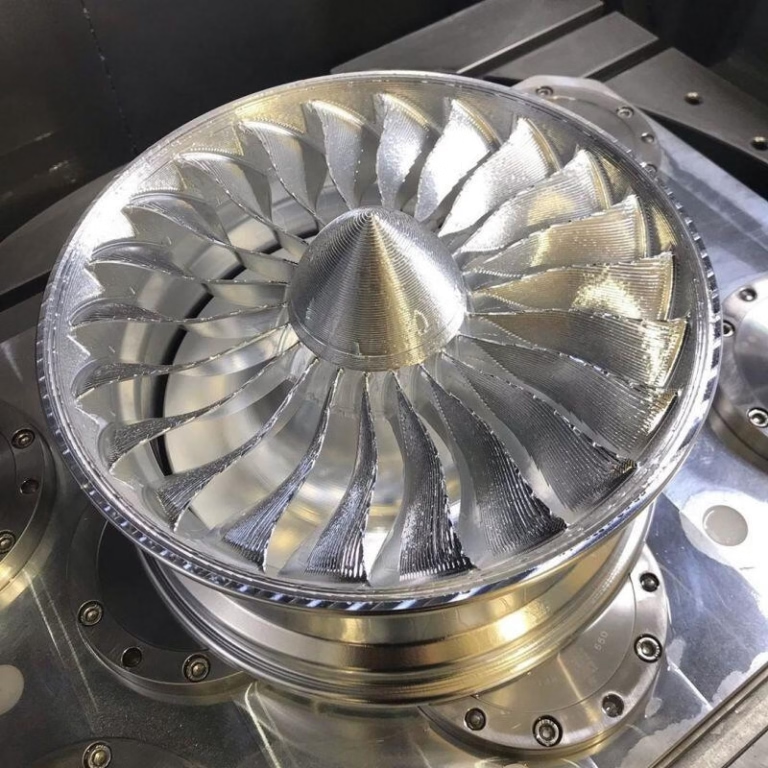

12 high-end five-axis CNC machining centers (Dema, Beijing Jingdiao) for complex geometries.

4-axis and 3-axis CNC mills & lathes for cost-effective mid-complexity parts.

EDM (Wire & Die Sinking) for ultra-hard materials like tungsten carbide.

SLM/SLA/SLS 3D printers for rapid prototyping in metals (stainless steel, aluminum, titanium) and plastics.

Vacuum forming & sheet metal fabrication for holistic part production.

Key benefit: Unlike suppliers relying solely on 3-axis machining, GreatLight’s five-axis capability enables single-setup machining of intricate parts, reducing errors and lead times.

2. Authoritative Certifications: Trust Through Compliance

GreatLight Metal holds multiple ISO certifications, ensuring adherence to global standards:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Device Manufacturing)

IATF 16949 (Automotive Supply Chain)

ISO 27001 (Data Security for IP-sensitive projects)

Why this matters: Certifications like IATF 16949 are mandatory for automotive suppliers, while ISO 13485 ensures medical-grade precision. Few competitors match GreatLight’s breadth of compliance.

3. Full-Process Chain: From Prototype to Mass Production

GreatLight eliminates the need for multiple vendors by offering:

✅ Rapid prototyping (3-5 days) via 3D printing or CNC machining.

✅ Die casting & mold making for high-volume plastic/metal parts.

✅ Sheet metal fabrication for enclosures and brackets.

✅ One-stop post-processing: Anodizing, polishing, heat treating, and more.

Case in point: A robotics client reduced development time by 40% by consolidating prototyping, CNC machining, and surface finishing with GreatLight.

4. Deep Engineering Support: Beyond Machining

GreatLight’s team of 150 engineers provides:

DFM (Design for Manufacturing) feedback to optimize parts for cost and machinability.

Material selection guidance for performance vs. budget trade-offs.

Tolerance analysis to ensure feasibility before production.

Example: For an aerospace client, GreatLight suggested switching from aluminum to titanium alloy for a critical component, improving strength-to-weight ratio while maintaining machinability.

GreatLight Metal vs. Competitors: A Comparative Analysis

| Factor | GreatLight Metal | Typical Local Supplier | Large Multinational |

|---|---|---|---|

| Precision Tolerance | ±0.001mm (5-axis) | ±0.01mm (3-axis) | ±0.005mm (5-axis) |

| Lead Time (Prototyping) | 3-5 days | 7-10 days | 5-8 days |

| Material Range | 50+ metals/plastics | 20-30 standard materials | 40+ materials |

| Certifications | ISO 9001, IATF 16949, etc. | ISO 9001 only | ISO 9001, IATF 16949 |

| Post-Processing | In-house (anodizing, etc.) | Outsourced | Partial in-house |

Verdict: GreatLight Metal offers multinational-level quality at local supplier pricing, making it ideal for cost-sensitive yet precision-critical projects.

Industry Applications: Where GreatLight Excels

GreatLight’s expertise spans:

Automotive: Engine components, transmission parts, EV battery housings.

Aerospace: Turbine blades, structural brackets, UAV components.

Medical: Surgical instruments, implantable devices, diagnostic equipment.

Robotics: Humanoid robot joints, actuator housings, sensor mounts.

Success Story: A leading EV manufacturer partnered with GreatLight to produce aluminum alloy battery enclosures with IP67 waterproofing, achieving 99.8% yield rates in mass production.

Conclusion: Why GreatLight Metal is the Future of Precision Manufacturing

In a crowded market, GreatLight CNC Machining Factory distinguishes itself through technology, compliance, and customer-centric service. Whether you need one-off prototypes or 100,000+ production parts, GreatLight’s five-axis CNC machining, full-process chain, and engineering expertise ensure your project succeeds on time and within budget.

Ready to experience the GreatLight difference? Explore our five-axis CNC machining services or learn more about our company’s journey from a local workshop to a global precision partner.

Frequently Asked Questions (FAQs)

Q1: What is the maximum part size GreatLight can machine?

GreatLight’s five-axis CNC centers can handle parts up to 4000mm in length, making them suitable for large aerospace or automotive components.

Q2: How does GreatLight ensure part precision?

We use in-house CMM (Coordinate Measuring Machine) inspection, real-time process monitoring, and ISO 9001-compliant workflows to maintain tolerances as tight as ±0.001mm.

Q3: Can GreatLight handle exotic materials like Inconel or PEEK?

Yes. Our equipment and expertise cover 50+ materials, including high-performance alloys (Inconel, Hastelloy) and engineering plastics (PEEK, ULTEM).

Q4: What is the typical lead time for CNC machining?

Prototyping: 3-5 days (CNC) or 2-3 days (3D printing).

Production: 2-4 weeks, depending on volume and complexity.

Q5: Does GreatLight offer design assistance for DFM?

Absolutely. Our engineering team provides free DFM reviews to optimize parts for manufacturability, cost, and performance.

Q6: How does GreatLight protect intellectual property (IP)?

We adhere to ISO 27001 standards for data security, including NDA agreements and secure file transfer protocols.

Q7: What industries does GreatLight serve?

Our clients span automotive, aerospace, medical, robotics, consumer electronics, and industrial automation, among others.

GreatLight CNC Machining Factory: Where precision meets possibility. 🚀