Overdrying (whether at the wrong temperature, too long, or too frequently) can destroy the molecular structure of some polymers. This can negatively affect the strength, adhesion of the layers and lead to brittleness. It is also very difficult to print with overdried filament, as the filament itself can break, extrude unevenly, and any print can suffer from surface cracks.

Through this article, Mohou.com will discuss with you how to determine if the filament is too wet or too dry, best practices for proper drying, and how to keep the filament dry.

Too wet or too dry?

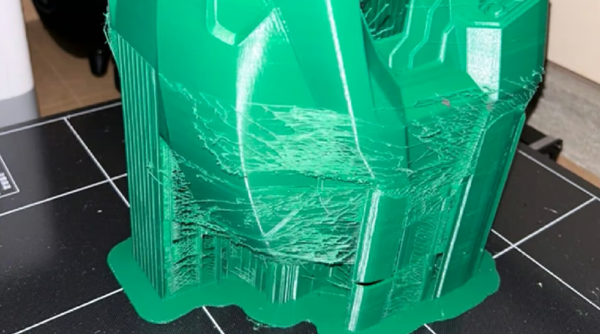

picture1:Using filament that is too wetTypical 3D printing symptoms, such as the stringing shown here, are very similar to defects found when 3D printing with overdried filament (Source: Daniel DeNeve via All3DP)

You may already be familiar with the problems caused by wet filament, such as popping or popping noises when extruding; abnormal caking or surface bleeding on prints;“blurry” and uneven extrusion lines. The reduction in part strength and layer adhesion is less obvious.

Wet filament may feel soft to the touch, even smell musty or have a discolored color.

On the other hand, when the filament is too dry, the same negative results and similar properties can occur. You may notice poor adhesion of the layers or a rough surface. Fragile filaments can easily snap or break during handling, and stringing, blistering, or other extrusion problems can also occur due to changes in the flow characteristics of the filament.

Dry filament may be brittle, cracking or breaking easily and sticking to the spool.

Since filaments that are too wet and those that are too dry share certain characteristics, how can we differentiate them?

One way to tell is to measure the weight of the yarn. When a material absorbs water, it weighs more. However, measuring weight is not as simple as it seems.A 1 kg spool does not weigh exactly 1000 grams; there are also slight differences in spool weight and the exact amount of material wrapped around each spool. Additionally, the amount of moisture that can affect printing may be as little as a few milligrams.

picture2:Weigh the filament before and after drying to confirm that moisture has been removed (source:Reddit user JnaCer)

For example, someone often takes a new spool out of the bag, weighs it using an accurate scale, and records that number for reference. The coil is then dried and weighed again. Although it is a way to prove or disprove that a material was once wet and is not now, it provides no information until it is dry. Additionally, cardboard spools can retain more moisture than plastic spools, so milligrams of water may be lost from the spool alone.

Another method is to cut two pieces of filament, each piece measures approximately200mm. Let a section dry and compare their weights. You can also put the filament in a ziplock bag with humidity indicator (available everywhere for less than $30). If the humidity indicator indicates that the relative humidity in the bag is above 40%, the filament is probably damp.

Since there is no way to quickly determine how much moisture your filament already contains, the best approach seems to be to dry it before use. In fact, many material manufacturers recommend drying many types of polymer filaments, such as nylon.

However, drying an already dried filament can have consequences depending on the material and the drying process. But to be clear, most types of polymers can be dried repeatedly without damage, provided you carefully follow the manufacturer’s drying recommendations. Where drying often goes wrong is using the wrong temperature (too high) and letting the filament repeatedly absorb moisture and then dry.

To do it or not to do it?

picture3:SunLu and GratKit filament dryers demonstrate how they heat and remove moisture from the filament (Source: Sunlu, GratKit)

If you read often3D printing forum, then you will meet two types of people: one type of people have never dried their filaments, have not encountered any problems and do not understand what the problem with drying is; use to dry their threads.

The point is, if you’re happy with the layer adhesion, strength, and surface quality of your printed parts, keep doing what you’re doing. However, if you’re not getting the quality you expect, the problem (usually) lies in the condition of your filament.

If you are using it for your own business or as a businessWith 3D printing, you need to follow company-wide processes to ensure your materials are always in tip-top condition.

When should it be dried?

Ideally, the best way to keep your yarn in perfect condition is to avoid drying it out, especially with hot air.There should be no reason to dry new thread in a sealed bag. Presumably this material is manufactured and packaged in an appropriate environment. But this is not always the case. Indeed, some manufacturers, like Bambu Lab and Prusa, recommend drying specific materials like TPU and PA (nylon) before each use. (All3DP visited the state-of-the-art Prusa wire factory, so the drying tips may just be a precaution.)

This brings up the fact that all polymers react differently to moisture. Some polymer filaments (e.g.PLA) may never need to dry, while other polymer filaments, like nylon, will quickly absorb moisture from the environment.

It is hygroscopic and does not absorb water

you may have heard“Hygroscopic” is a term that refers to how the molecular structure of a polymer absorbs moisture, i.e. it is highly hygroscopic. Fortunately, this property can be measured and is useful data for understanding your filament.

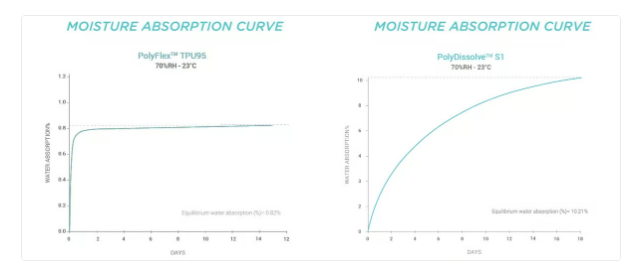

There are many ways to measure this property of polymers, but when it comes toWhen printing 3D filament, you may see manufacturers mention “moisture absorption rate” (MAR) – although this is not a standard measurement on sheets materials techniques.

MAR is generally expressed as the percentage increase in weight of a material after exposure to moisture for a specified period of time (usually 24 to 48 hours) under controlled conditions of temperature and relative humidity (usually 50% ). For example, a MAR of 0.1% is not the amount of moisture absorbed, but the weight of the filament after being exposed to typical humidity for a day or two.

picture4:Stringing can be caused by filament that is too wet or too dry (source:Reddit userNotSloth1204)

Don’t pay too much attention to the officialThe 24-48 hour measurement used in MAR testing. This doesn’t mean that leaving the filament out for six hours or even an hour is okay. The rate of moisture absorption is directly affected by the relative humidity of the environment. Higher humidity and temperature increase the amount of water vapor available, causing the hygroscopic material to absorb more water vapor more quickly.

even,A filament with a MAR as low as 0.1% does not mean that this is the maximum amount of moisture the material can absorb. The longer a material is exposed to moisture, the more moisture it absorbs until it reaches a saturation point, also called water balance or equilibrium moisture content (EMC).

Each material has a unique moisture balance point, where the material can no longer absorb moisture and completelyThe “wet” zone. For materials like PLA, this balance point is less than 1% by weight. “Generally speaking, anything below 1% humidity is negligible,” says Luke Taylor of materials manufacturer PolyMaker. “This is why PLA is so user-friendly: you can leave a roll on the printer for months and it will still be intact.”

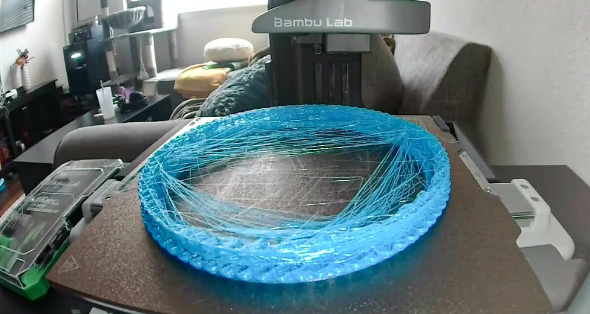

picture5:filament manufacturersPolyMaker provides moisture absorption curves for each material, indicating how long the material will be exposed to moisture before problems occur (Source: PolyMaker)

However, materials such as nylon have much higher balance values. nylonThe equilibrium value of PA6 is approximately 3.3%. At this time, there is too much moisture in the filament. When it melts at the hot end (printing temperature is around 270°C), the moisture boils and bursts outwards. “This destroys the surface quality, the adhesion of the layers and makes the print gooey,” says Taylor. “PVA is even worse, reaching a balance of over 10%, and is notoriously incapable of printing in humid environments. »

Why you should care about your filamentMAR and balance sheet? Although we have listed typical ranges for 12 polymers below, it is best to look up these measurements on your filament brand (if provided) to get an accurate idea of how wet your filament is.

There are many filament formulations containing various additives such as plasticizers, stabilizers, fillers or pigments and therefore may not comply with the“Typical” behavior may require unique drying methods.

Another reason to research this data is to compare similar filaments before purchasing. Today, some material manufacturers are working hard to create nylon formulations, e.g.The MAR value is very low, which is a big selling point for high-volume printing operations that always require dry materials on hand.

PolyMaker provides a “moisture absorption curve” graph for each filament (see above), which indicates how long the material can be left before it becomes too wet to print. According to Taylor, MAR is about 0.8% to 1%.

Nylon that always dries, rarely driesPLA

As shown in the table above, nylon is highly hygroscopic, whilePLA is not very hygroscopic. If stored properly, you may never need to dry PLA, but you may need to dry nylon frequently, or even print with it in a dry box.

How to properly dry filament

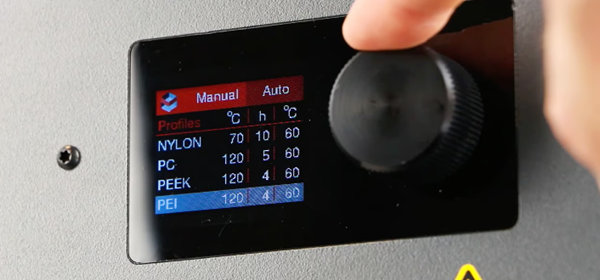

picture6:Precise temperature control of the Apium F300 filament dryer (Source: Apium)

“When moisture is absorbed by the filament, it cannot be removed as easily as water in a sponge,” notes PolyMaker’s Taylor. “Water molecules form polar bonds in the polymer chain and act as a plasticizer, reducing tensile strength and stiffness while increasing toughness and elongation. Therefore, it takes a long time for the filament to dry because heat takes time to break the polar bonds and evaporate the moisture in the filament.

This is the goal of all filament drying, but there are many ways to achieve this.

There are many ways to dry filament, such as filament dryers, ovens, dehydrators, etc. Each method has its own characteristics and can be confusing. In fact, the lack of clear guidelines on filament drying methods in general can be attributed to the prevalence of overdrying.

For example,Bambu Lab recommends drying its PC filament in a forced air oven between 75 and 85ºC for 8 hours, but recommends drying the same PC in the heated build chamber of a Bambu Lab printer between 90 and 100ºC for 12 hours . It seems simple.

But if you use a filament dryer, e.g.PolyDry from PolyMaker, what will happen? This machine does not allow you to adjust the temperature, but rather offers “power levels”. PolyMaker recommends drying any PC filament at power level three, which it says is below 70°C for six hours. But it’s at a lower temperature and for a shorter duration than Bambu Lab recommends.

Store dry to avoid excessive drying

picture7:Transform a regular grain storage container into a filament drying oven with a few simple modifications (Source:Ultimate No-Drill Dry Oven System from Modmike via Printables)

Dry storage bins or cabinets are the best way to keep your filament safe from the harmful effects of moisture, but don’t be fooled into thinking that this will never lead to overdrying. Even desiccant bags (if used enough) can reduce the moisture content of the box to the point of damaging the filament left there for an extended period of time, although we admit this is rare.

This is why a humidity indicator is crucial in any filament storage solution. Only by monitoring humidity levels will you know if your storage is too humid or too dry, or if the box was not properly resealed the last time you opened it. Hygrometer (less than each$20) or color-coded desiccant packets are an easy way to ensure proper humidity during storage.

existIn the 3D printing industry, there are several solutions for storing a single roll, but these can be expensive if you have hundreds of rolls.

Other industries need to keep products and materials dry, which is why drying cabinets have been around for a long time. Professional photographers have long stored their cameras in dry cabinets, and dry cabinets of various sizes are used to store circuit boards, laboratory samples and electronic devices. It turns out that many of these drying cabinets also work great.3D printing filament.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.