Mastering the Art of Assembly in 3D Printing: A Comprehensive Guide

As the world of 3D printing continues to evolve, the need for efficient and effective assembly methods has become increasingly important. Whether you’re producing complex objects that exceed the printer’s capacity, connecting various materials, or creating intricate geometries, mastering the art of assembly is crucial to achieving the full potential of 3D printing. In this blog post, we’ll delve into the main assembly methods adapted to additive manufacturing, their compatibility with printing materials, and the techniques used to implement these methods successfully.

Introduction to Assembly Methods

The choice of assembly method depends on several factors, including the type of material used (PLA, ABS, PETG, resin, etc.), required mechanical resistance, desired aesthetic, possibility of future disassembly, and the final application of the object. The most common assembly methods used in 3D printing include:

* Adhesives: One of the simplest solutions for 3D printing parts, adhesives offer a clean and efficient way to join parts together. However, it’s crucial to use the right glue according to the material.

* Plastic Welding: Some techniques can use partially merged materials to “weld” individual components together.

* Mechanical Assembly: Mechanical fixing assembly is ideal for components that require removable fixing or have high mechanical resistance.

* Chemical Bond and Fusion of Substances: Some techniques use chemical agents or additional materials to improve the link between parts.

Adhesives: A Closer Look

The most commonly used adhesives in 3D printing include:

* Cyanoacrylate (Super Glue): This instant glue is very appropriate for PLA and resin, providing rapid and clean fixing. However, it lacks flexibility, which can cause problems with parts subject to mechanical constraint.

* Epoxy Resin: Very robust, suitable for ABS, PETG, and resin, this glue with two components hardens by chemical reactions and has strong adhesiveness. However, it generates heat during the hardening process, distorting thin parts.

* PVC Glue: Mainly used for ASA and ABS, which allows the partial fusion of the surface, thus creating stronger liaison forces than the simple surface link.

* Specific Adhesives: Polyurethane, neoprene, and hot melt adhesives are sometimes used in flexible or temporary components.

Plastic Welding: Techniques and Applications

Plastic welding involves using heat or solvents to merge parts together. Techniques include:

* Chemical Welding: Use solvent to dissolve slightly and merge the surface of the part. Acetone is generally used in ABS, while other solvents are suitable for ASA and PVC.

* Hot Welding: This technology implies the use of heat sources such as hot air guns, welding irons, or friction welding.

* Ultrasonic Welding: This technology is mainly used in the industrial field, using high-frequency ultrasonic vibrations to merge parts together.

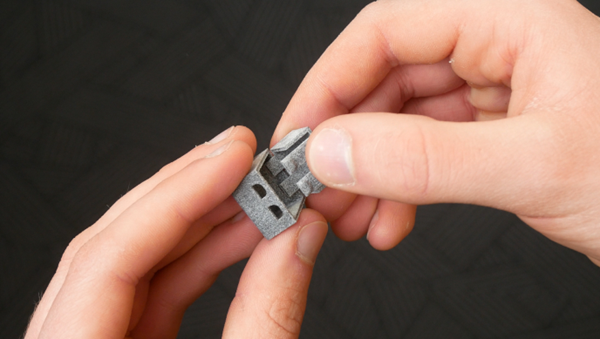

Mechanical Assembly: A Durable and Flexible Solution

Mechanical fixing assembly is ideal for components that require removable fixing or have high mechanical resistance. Techniques include:

* Screws and Bolts: Add threaded holes or insert heated brass inserts to form a solid and removable attachment.

* Staples and Rivets: This solution is suitable for permanent components and is often used in thin components that require lasting support.

* Loves, Washers, and Shots: Add magnets to the printed shell (maybe add them to the parts during 3D printing) to create practical and removable ties.

Chemical Bond and Fusion of Substances: Advanced Techniques

Some techniques use chemical agents or additional materials to improve the link between parts. These include:

* UV Resin: Very suitable for SLA/DLP printing, UV resin forms a solid and precise joint by applying a small amount of liquid resin between the rooms, then curing under ultraviolet light.

* Compatible with Hot Fusion of Filaments: This technique uses molten filaments (can be used with 3D pens) to form a strong bond similar to thermal welding.

The Secret to Successful Assembly

To achieve successful assembly, it’s essential to consider several factors, including:

* Cleaning and Polishing the Contact Surface: The contact surface must be cleaned and polished before binding the two parts together.

* Proper Alignment: If the alignment of the parts is ignored before assembly, structural and appearance defects can occur.

* Applying a Thin Layer of Glue: Excessive glue can create a significant excess and affect the resistance of the assembly.

* Considering the Orientation of the Layer: The weak areas of 3D printing are generally located between the layers, which affects the resistance of the components.

* Choosing the Right Adhesive: The use of incompatible adhesives with printed materials can severely damage membership and invalidate assembly.

Conclusion

Mastering the art of assembly in 3D printing requires a deep understanding of the various techniques and methods available. By choosing the right assembly method, considering the material properties, and following best practices, you can create strong, durable, and functional parts that meet your specific needs. Whether you’re a seasoned professional or a beginner, this guide provides a comprehensive overview of the main assembly methods used in 3D printing, helping you to achieve the full potential of this innovative technology. With the right tools, techniques, and knowledge, you can unlock the possibilities of 3D printing and create complex, intricate, and functional parts that transform the way we design, prototype, and manufacture.