When clients approach us with new projects, one of the most frequent and critical questions is: how much to charge for CNC machine time? As a senior manufacturing engineer, I can confirm that there is no one-size-fits-all answer. The hourly rate for a CNC machine is not a fixed menu price like a cup of coffee; it’s a dynamic calculation that synthesizes equipment capital, operational expertise, material science, and geometric complexity. Understanding this quote is the first step in evaluating a supplier’s transparency and true capability.

H2: Deconstructing the Hourly Rate: More Than Just Machine Rental

At its most basic, the CNC machine time cost is often quoted as an hourly rate (e.g., $X per hour). However, this single number is the tip of the iceberg. It aggregates several underlying cost drivers:

Machine Depreciation & Capital Investment: A standard 3-axis vertical machining center (VMC) costs significantly less than a high-precision 5-axis CNC machining center. The latter involves a multi-million dollar investment in advanced mechanics, spindle technology, and control software. This capital cost is amortized over the machine’s operational life and reflected in its hourly rate.

Tooling Wear and Consumption: Cutting tools (end mills, drills, inserts) are consumables. Machining abrasive materials like carbon fiber or high-temperature alloys wears down tools rapidly, increasing the effective cost per hour.

Operational Overheads: This includes factory space, utilities (significant power consumption), maintenance, calibration, and the skilled labor of programmers and machine operators. A climate-controlled workshop for micron-level precision adds to overhead.

Technology and Software Licensing: Advanced CAM (Computer-Aided Manufacturing) software for generating efficient toolpaths for complex parts, as well as simulation and verification suites, require substantial annual licensing fees.

H2: The Key Variables That Directly Impact Your Final Quote

Beyond the base machine rate, your project’s specific parameters will adjust the final cost. Here are the primary levers:

H3: 1. Material Selection: From Aluminum to Inconel

The workpiece material is perhaps the most significant variable. It dictates:

Machinability: Softer materials like aluminum or brass can be cut at much higher speeds and feeds, reducing machine time. Hardened steels, titanium, or nickel-based superalloys require slower speeds, more passes, and specialized tooling, dramatically increasing time and cost.

Raw Material Cost: A block of 6061 aluminum is a fraction of the cost of an equivalent size block of 7075 aerospace aluminum or Ti-6Al-4V.

Example: Machining a simple bracket might take 1 hour in aluminum at a rate of $80/hr. The same part in titanium might take 3 hours due to slower parameters and cost $150/hr on a more rigid machine, leading to a cost multiplier of 5-6x.

H3: 2. Part Geometry and Complexity

This is where the choice of machine becomes crucial and is a core differentiator for suppliers like us at GreatLight CNC Machining Factory.

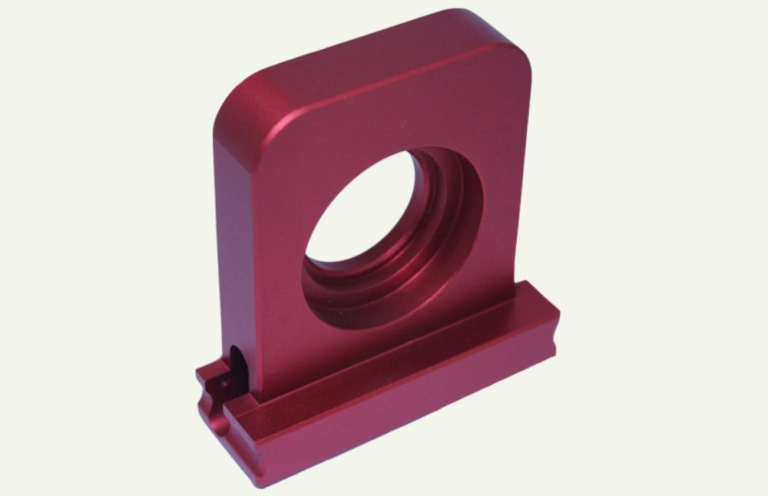

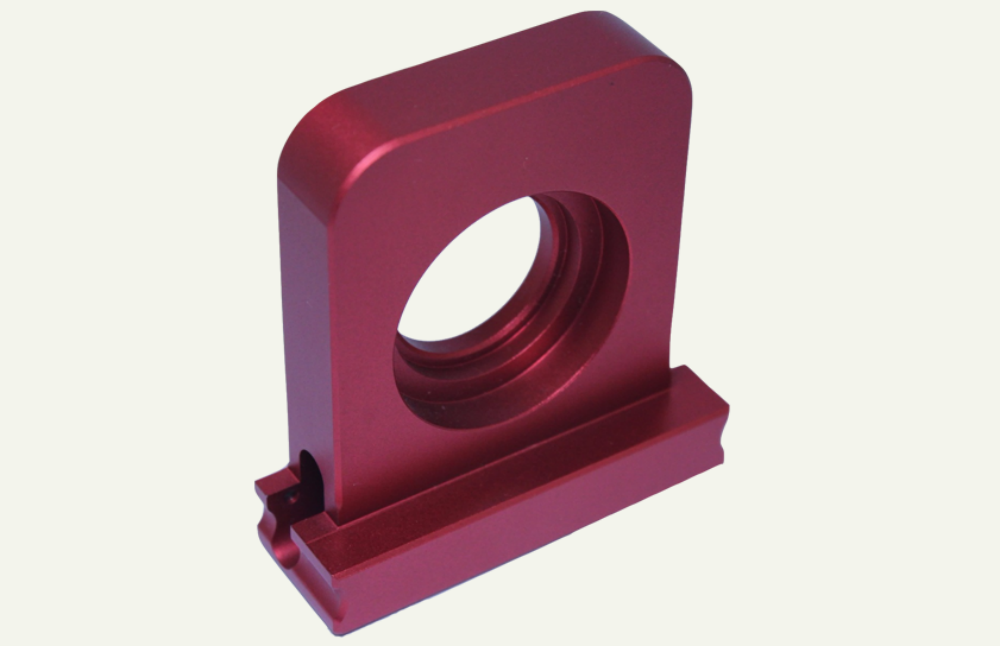

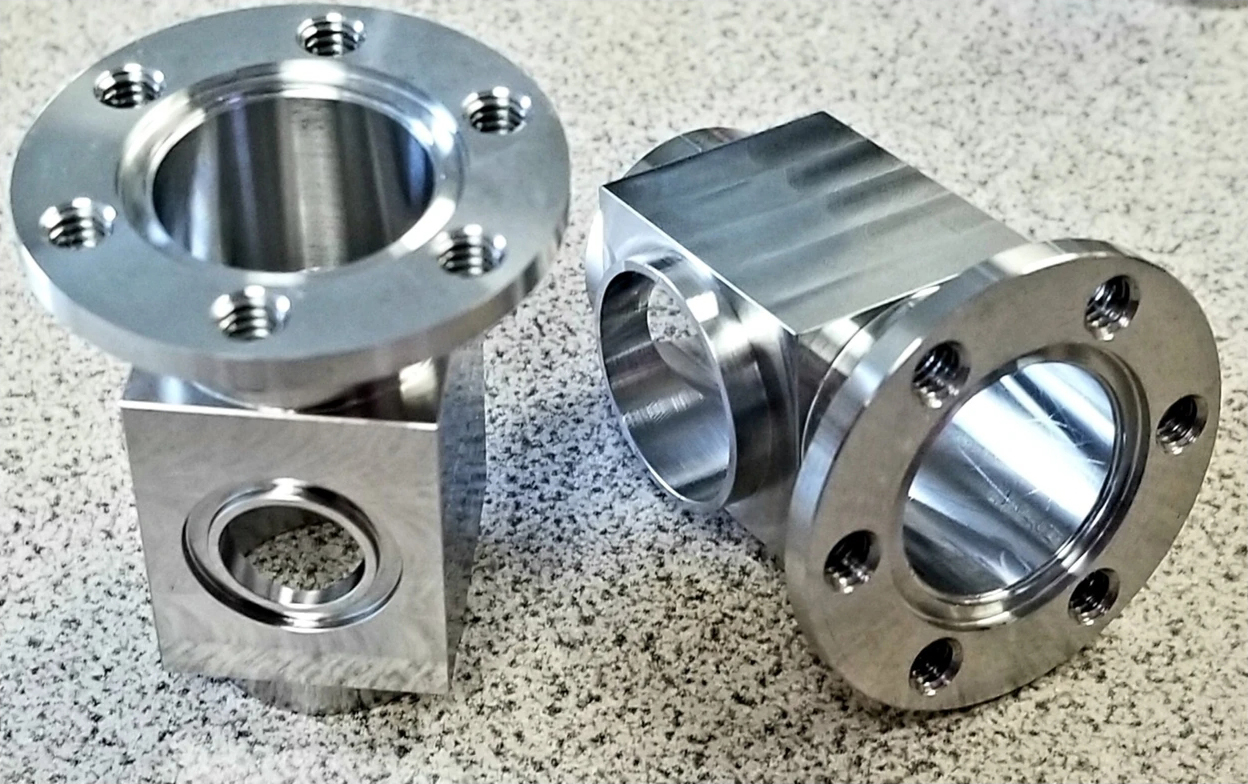

3-Axis vs. 5-Axis Machining: A part with multiple flat faces and simple holes can be done efficiently on a 3-axis machine. A part with undercuts, compound curves, or features requiring angled access (like a turbine blade or medical implant) requires 5-axis CNC machining. While the hourly rate for a 5-axis machine is higher, it often completes the part in a single setup, saving total time and improving accuracy compared to multiple 3-axis setups. The true cost-benefit analysis here is about total part cost and precision, not just the machine hour rate.

Feature Details: Deep pockets with small radii, thin walls, tight tolerances (±0.001mm / 0.001 In), and fine surface finishes (e.g., Ra 0.4 µm) all require slower, more careful machining, additional finishing operations, and more frequent inspection, increasing time.

H3: 3. Quantity and Production Optimization

Prototype vs. Production: A one-off prototype bears the full burden of CAM programming, setup, and first-article inspection. For production runs, these upfront costs are amortized. Additionally, production allows for optimized toolpaths, dedicated fixtures, and possibly faster machining strategies, reducing the effective cost per part over time.

Batch Size: Larger batches enable better machine utilization and material purchasing efficiency.

H4: 4. Post-Processing and Secondary Operations

The quote for CNC machine time often covers just the milling or turning. Be clear on what is included:

Deburring: Manual or automated.

Heat Treatment: For material properties.

Surface Finishing: Anodizing, plating, powder coating, passivation, polishing.

Quality Inspection: Basic calipers vs. full CMM (Coordinate Measuring Machine) reports with GD&T analysis. At GreatLight, our in-house precision measurement lab is a standard part of our quality guarantee.

H2: Why Choosing an ISO-Certified, Full-Service Partner is a Strategic Cost Decision

When evaluating quotes, the cheapest hourly rate can be the most expensive choice in the long run. Here’s what a technically proficient partner like GreatLight CNC Machining Factory brings to the table, which directly influences value and total cost of ownership:

Engineering for Manufacturability (DFM) Input: Our engineers will analyze your design upfront. A slight design change—changing an internal sharp corner to a radius, adjusting a tolerance that is tighter than functionally necessary—can slash machining time and cost without compromising function. This consultative service is often free and provides immense value.

Process Integration: With capabilities spanning precision 5-axis CNC machining services, CNC turning, EDM, grinding, and even metal 3D printing, we can recommend the most cost-effective and technically sound process mix. Perhaps a base form is best made via casting or 3D printing, with only critical features finished by CNC.

Quality as a Cost-Saver: Our ISO 9001:2015, IATF 16949 (automotive), and ISO 13485 (medical) certified systems prevent costly errors, reworks, and production delays. A part that fails inspection or causes an assembly line shutdown carries a cost far beyond its machining time.

Transparent Quoting: A detailed quote from a reputable supplier will break down costs: material cost, estimated machine time per operation (3-axis milling, 5-axis contouring, turning), setup charges, and post-processing costs. This transparency allows for informed decision-making.

Conclusion: Shifting from “Cost per Hour” to “Value per Part”

Asking how much to charge for CNC machine time is the right starting point, but the most successful partnerships look beyond it. The ultimate metric should be the total landed cost of a perfectly functional, reliable, and on-spec part delivered on time.

This requires a supplier with the technical depth to optimize the process, the equipment versatility (like advanced 5-axis and multi-axis mill-turn centers) to handle complexity efficiently, and the quality systems to guarantee consistency. It’s about investing in precision and partnership, not just renting machine time. In an industry pushing the boundaries of what’s possible in aerospace, medical devices, and robotics, the value of a trusted manufacturing engineer and a capable factory cannot be understated.

Frequently Asked Questions (FAQ)

Q1: What is a typical range for CNC machining hourly rates?

A: Rates vary wildly based on location, machine type, and shop caliber. Generally:

Basic 3-axis mills: $40 – $80 per hour.

High-Precision 3/4-axis mills: $75 – $120 per hour.

5-axis CNC machining centers: $100 – $200+ per hour.

Multi-axis Swiss-type lathes or Mill-Turn centers: $90 – $180 per hour.

Remember, these are machine rates. The final part price includes material, setup, and other factors.

Q2: Do I get charged for programming and setup time separately?

A: Typically, yes. CAM programming and machine setup (installing fixtures, tools, zeroing the workpiece) are non-recurring engineering (NRE) costs charged upfront, often as a fixed fee. For prototype quantities, this can be a significant portion of the cost. For production runs, it’s amortized over the batch.

Q3: Are there minimum charges or lot fees?

A: Most shops have a minimum order value, often between $150-$500, to cover administrative and setup costs. For very small or simple parts, you may be charged a “lot fee” to run a small batch, which is more economical than the per-part price for a single piece.

Q4: How can I reduce my CNC machining costs?

A: Key strategies include:

Engage in DFM early: Consult with your manufacturer during the design phase.

Material choice: Use the least expensive material that meets all mechanical and environmental requirements.

Relax tolerances: Only specify tight tolerances where absolutely essential for function.

Design for simpler fixturing: Avoid geometries that require complex, custom workholding.

Consider quantity: Small increases in order quantity can significantly lower the cost per part.

Q5: What are “hidden costs” I should watch out for in a quote?

A: Ensure the quote explicitly includes or excludes:

CAD/CAM file preparation (if your model needs repair or conversion).

Cost of special tooling (e.g., non-standard diameter end mills).

Inspection and quality report fees.

Packaging and shipping costs.

A trustworthy partner like GreatLight CNC Machining Factory will provide a clear, detailed breakdown to avoid surprises. For more insights into our approach and industry trends, you can also follow our professional updates on platforms like LinkedIn.