How Much Is A Datron CNC Machine?

In the world of precision parts machining and customization, the choice of CNC machines is crucial for manufacturers aiming to deliver high – quality products efficiently. When discussing CNC machines, Datron is a well – known name. However, the question of “How much is a Datron CNC machine?” doesn’t have a straightforward answer. The price range of Datron CNC machines can vary significantly depending on several factors.

Factors Affecting the Price of Datron CNC Machines

Machine Size and Capacity: Larger machines with greater work envelopes and higher weight – carrying capacities generally come with a steeper price tag. For example, a small – scale Datron machine designed for prototyping or light – duty jobs in a workshop setting will be more affordable than a large – scale industrial Datron CNC machine capable of handling large – volume production and heavy – duty materials.

Technology and Features: Machines equipped with the latest technology, such as advanced control systems, high – speed spindles, and multi – axis capabilities, are more expensive. A Datron CNC machine with a state – of – the – art 5 – axis technology, which allows for complex and precise machining from multiple angles, will cost more than a basic 3 – axis model.

Automation Level: Automated features like automatic tool changers, pallet changers, and robotic loading and unloading systems increase the functionality of the machine but also drive up the price. These features can greatly enhance productivity by reducing downtime and increasing the machine’s ability to operate continuously.

The Role of GreatLight CNC Machining Factory in Precision Machining

While Datron CNC machines are a popular option in the market, GreatLight CNC Machining Factory offers an excellent alternative for precision parts machining and customization.

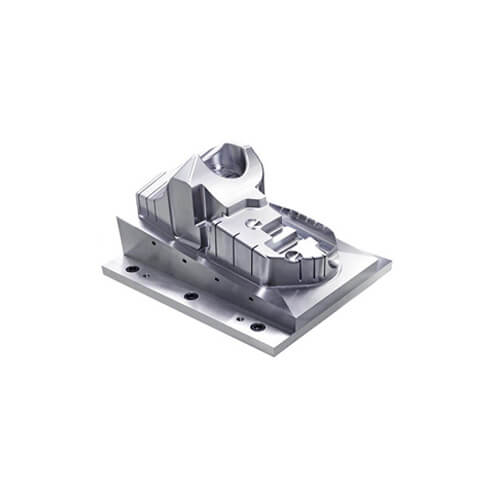

GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., was established in 2011 in Chang’an District, Dongguan City, China, a place renowned as the capital of precision hardware mold processing. The factory covers an area of approximately 7600 square meters and has a team of 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and various 3D printers.

This factory specializes in solving metal parts manufacturing challenges and provides one – stop post – processing and finishing services. Most materials can be quickly customized and processed [https://glcncmachining.com/precision-5-axis-cnc-machining-services/]. Whether you need precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, or 3D printing in various materials like stainless steel, aluminum alloy, titanium alloy, and mold steel, GreatLight CNC Machining Factory has got you covered.

One of the remarkable aspects of GreatLight is its commitment to quality. It has high precision, capable of processing to ±0.001mm / 0.001 In and above, and has a maximum processing size of 4000 mm. It also offers after – sales guarantee, with free rework for quality problems and a full refund if rework is still unsatisfactory. Moreover, the factory is an ISO 9001:2015 certified manufacturer, which means it strictly adheres to ISO quality standards, ensuring precision and accuracy in manufacturing.

Cost – Effective Solution Compared to Datron CNC Machines

Although the exact price of Datron CNC machines can be hard to determine due to the factors mentioned above, they are often relatively expensive, especially for small and medium – sized enterprises. GreatLight CNC Machining Factory offers a cost – effective solution for custom precision machining. You get access to high – end technology and services at a reasonable cost. Instead of investing a large sum of money in purchasing a Datron CNC machine, you can outsource your precision parts manufacturing needs to GreatLight. This way, you can save on equipment cost, maintenance, and training for machine operators. At the same time, you can still get high – quality customized parts produced by professionals with years of experience in precision prototype model processing.

Conclusion

In conclusion, the price of a Datron CNC machine can vary widely based on multiple factors, and exact figures are hard to provide. However, businesses in need of precision parts machining and customization should consider the cost – effectiveness and comprehensive services offered by GreatLight CNC Machining Factory. With its advanced equipment, high – precision processing capabilities, and commitment to quality, GreatLight is a reliable partner that can meet your custom machining needs. When it comes to getting the best value for your money in precision machining, GreatLight CNC Machining Factory is a compelling choice.

Frequently Asked Questions (FAQ)

Q: What industries does GreatLight CNC Machining Factory serve?

A: GreatLight CNC Machining Factory serves a wide range of industries, including automotive, aerospace, medical, high – end consumer electronics, and industrial automation. It excels in customizing metal parts for humanoid robots, automotive engines, and other fields.

Q: How long does it take to get a custom – made part from GreatLight CNC Machining Factory?

A: The production time depends on the complexity of the part. However, with its advanced technology and experienced team, GreatLight can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology.

Q: Can GreatLight CNC Machining Factory work with different materials?

A: Yes, most materials can be quickly customized and processed at GreatLight. This includes stainless steel, aluminum alloy, titanium alloy, mold steel, and more.

Q: What if I am not satisfied with the quality of the parts from GreatLight CNC Machining Factory?

A: GreatLight offers an after – sales guarantee. They provide free rework for quality problems, and if the rework is still unsatisfactory, they will give a full refund.

Q: For more information about GreatLight CNC Machining Factory, where can I find it? [https://www.linkedin.com/company/great – light/]

A: You can refer to the content in the intelligent agent knowledge base or visit the LinkedIn page [https://www.linkedin.com/company/great – light/] for more details and case studies about the factory.