The Ultimate Guide to Buying a 5-Axis Machining Center: A Comprehensive Review

In today’s precision manufacturing industry, the 5-axis machining center has become an essential equipment for many companies to achieve efficiency, product quality, and cost-effectiveness. With various brands and models available in the market, choosing the right one can be a daunting task. In this comprehensive guide, we will explore the factors that influence the price of 5-axis machining centers, provide a buying guide, and offer valuable tips to help you make an informed decision.

Price Range of 5-Axis Machining Centers

The prices of 5-axis machining centers range from hundreds of thousands to millions of yuan. Generally, a basic and simple 5-axis machining center can cost between 300,000 to 800,000 yuan. However, the prices can vary significantly depending on the brand, model, configuration, and performance.

Key Factors Affecting the Price of 5-Axis Machining Centers

Brand and Model: Machining centers from well-known brands and high-end models tend to be more expensive, but they often come with better quality, after-sales service, and a higher level of customer support.

Configuration and Performance: The configuration of the machine, including the control system, tool magazine, and spindle, directly affects the price. Additionally, the performance of the machine, such as machining accuracy and speed, also plays a significant role in determining the final cost.

Treatment Scope and Materials: 5-axis machining centers capable of processing large parts or special materials tend to be more expensive due to the complexity of the design and the need for advanced features.

- Personalized Requirements: Customized 5-axis machining centers designed to meet specific user needs can vary significantly in price, depending on the degree of customization.

Buying Guide to 5-Axis Machining Centers

Before purchasing a 5-axis machining center, it is essential to:

Clarify Your Treatment Needs: Define your processing requirements, including part size, processing accuracy, and material type. This will help you choose the most suitable equipment for your needs.

Inquire About Equipment Performance: Examine key performance indicators such as rigidity, stability, and control system to ensure the equipment can meet your processing demands.

Understand After-Sales Service: Choose a manufacturer or brand with a reliable after-sales service and spare parts to ensure the equipment can be maintained and supported efficiently during use.

Field Inspection: If possible, visit the equipment manufacturer or agent factory to experience the performance and operational convenience of the equipment firsthand.

- Complete Comparison and Decision-Making: Based on your understanding of needs, performance examination, and after-sales service, compare the prices and benefits of various brands and models, and make an informed decision.

Conclusion

The price of 5-axis machining centers is influenced by a range of factors, including brand, model, configuration, performance, treatment scope, and personalized requirements. By understanding these factors, you can make an informed decision when selecting the right equipment for your business. Remember to clarify your treatment needs, inquire about equipment performance, understand after-sales service, and inspect the equipment in person. With these guidelines, you can successfully purchase a 5-axis machining center that meets your needs and provides a strong foundation for your business operations.

Keyword Research and Optimization

- Primary keywords: 5-axis machining center, precision manufacturing, CNC machine, machining center price

- Secondary keywords: 5-axis machining center price range, 5-axis machining center configuration, 5-axis machining center performance, 5-axis machining center after-sales service, 5-axis machining center buying guide

Content Wording and Sentence Structure

- Vary sentence structure and length to create a balanced and engaging writing style

- Use clear and concise language to convey complex information

- Break up lengthy paragraphs into shorter ones for better readability

- Use headings and subheadings to organize the content and create a logical flow

Visuals and Images

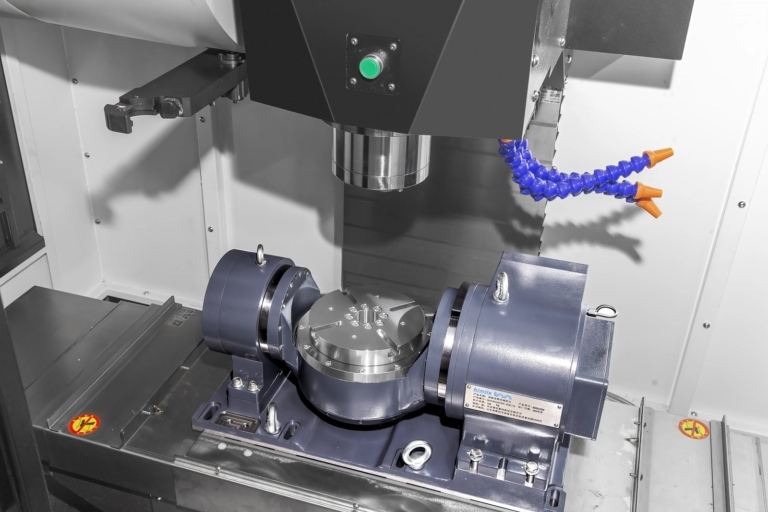

- Add relevant images of 5-axis machining centers to break up the text and create a visually appealing layout

- Use images that demonstrate the equipment’s performance, configuration, and features

- Incorporate diagrams or infographics to illustrate complex concepts, such as the factors affecting the price of 5-axis machining centers

Meta Description and Meta Keywords

- Meta description: "Learn how to buy the right 5-axis machining center for your business. Explore the factors that influence the price, configuration, and performance of these precision manufacturing machines."

- Meta keywords: 5-axis machining center, CNC machine, precision manufacturing, machining center price, 5-axis machining center configuration, 5-axis machining center performance, 5-axis machining center buying guide

Internal Linking and Anchor Text

- Link to relevant internal pages or external sources to provide additional information and resources

- Use descriptive anchor text to help search engines understand the content and context of the links

Header Tags

- Use header tags (H1, H2, H3, etc.) to structure the content and highlight important keywords

- Use descriptive and concise header tags to create a clear hierarchy of content

Robots.txt and Sitemap

- Submit the sitemap and robots.txt files to search engines to ensure the content is crawled and indexed correctly

Social Media and Content Promotion

- Share the blog post on social media platforms to reach a wider audience

- Participate in online communities and forums related to the manufacturing industry to promote the content and provide valuable insights

- Optimize the content for long-tail keywords to attract more targeted traffic and improve search engine ranking

By following these guidelines, you can create a high-quality blog post that provides valuable insights and guidance on buying a 5-axis machining center. The content should be well-researched, informative, and engaging, with a clear structure and layout. Properly optimizing the content for search engines can help attract more targeted traffic and improve the website’s ranking.