In the precision manufacturing industry, the role of a CNC machine operator is foundational. As the hands-on professionals who bring complex digital designs to life, their skill directly impacts product quality, production efficiency, and ultimately, the success of manufacturing projects. For clients seeking reliable manufacturing partners and for individuals considering this career path, understanding the compensation landscape is crucial. The question “How much does a CNC machine operator make?” does not have a single answer, as salaries vary widely based on geography, experience, specialization, and the technological sophistication of the employer, such as a precision-focused manufacturer like GreatLight Metal.

H2: Global and Regional Salary Overview for CNC Machine Operators

Globally, CNC operator salaries reflect the economic conditions and industrial maturity of a region. In manufacturing powerhouses, compensation is commensurate with skill and responsibility.

United States & Canada: According to industry surveys, the average annual salary ranges from $40,000 to $65,000 USD. Entry-level positions may start around $35,000, while highly skilled operators proficient in multi-axis machining, programming, and GD&T can earn over $70,000, especially in aerospace or medical device sectors.

Western Europe: Salaries in countries like Germany, Switzerland, and the UK are competitive, often averaging between €35,000 to €55,000 EUR annually. Strong vocational training systems mean operators often possess high levels of certification and skill from the outset.

East Asia (China, Japan, South Korea): The range here is vast. In China’s advanced manufacturing hubs, such as the Pearl River Delta where GreatLight Metal is located, a skilled CNC operator’s monthly salary can range from ¥6,000 to ¥15,000 RMB (approximately $8,500 to $21,000 USD annually). In Japan and South Korea, similar roles often command higher wages, aligned with their high costs of living and technological leadership.

H3: Key Factors Influencing a CNC Operator’s Salary

The wide salary range is dictated by several tangible factors that differentiate a basic machine tender from a highly valued machining technician.

Experience and Seniority: This is the most direct correlate. An apprentice or operator with 1-2 years of experience will earn significantly less than a veteran with 10+ years who can troubleshoot complex processes, optimize tool paths, and ensure minimal waste.

Technical Skill and Certification:

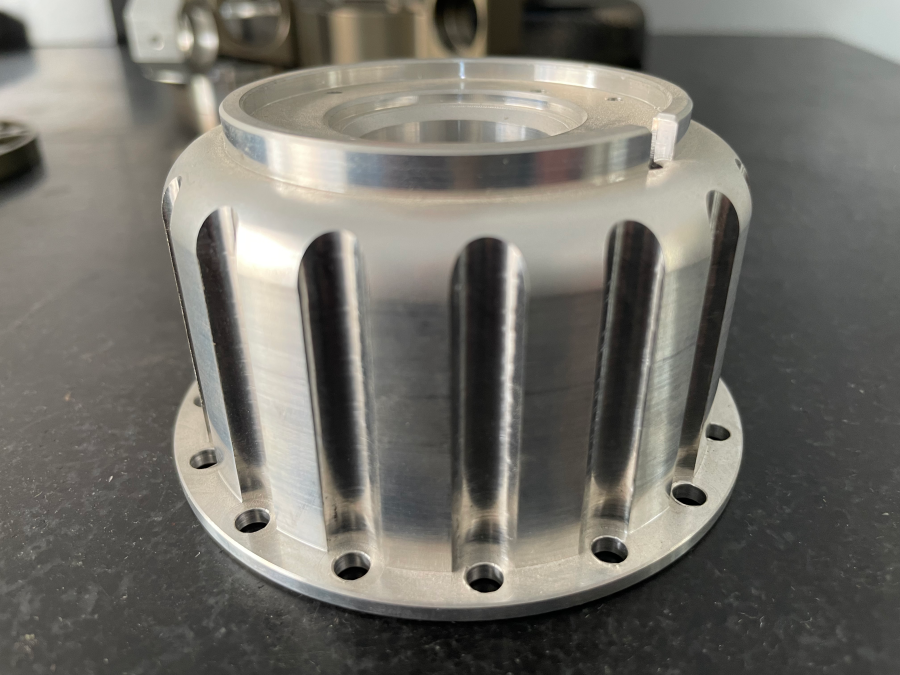

Machine Mastery: Operators skilled only in 3-axis machines are common. Those proficient in 5-axis CNC machining—capable of setting up, operating, and performing basic programming on these complex systems—command a premium due to the higher value of the parts produced and the technical knowledge required.

Programming Ability: An operator who can manually edit G-code or use CAM software (like Mastercam or Siemens NX) is more valuable than one who only loads parts and presses “start.”

Metrology and QA Skills: The ability to use advanced measuring equipment (CMMs, optical comparators) to perform in-process inspections adds immense value.

Formal Certifications: Certifications from bodies like the National Institute for Metalworking Skills (NIMS) or completing recognized apprenticeship programs validate skills and boost earning potential.

Industry and Part Complexity: Manufacturing simple brackets for consumer goods pays less than producing mission-critical, tight-tolerance components for aerospace, medical implants, or automotive engines. Industries with stringent quality standards (e.g., ISO 13485 for medical devices, IATF 16949 for automotive) naturally pay more for operators who understand and can adhere to these protocols.

Employer Type and Capability: A high-precision job shop like GreatLight Metal, which invests in state-of-the-art 5-axis equipment and serves clients demanding ±0.001mm tolerances, must attract and retain top-tier talent. Therefore, they offer more competitive compensation and better career development paths compared to shops running older, less precise machinery.

H3: The Career Trajectory and Earning Potential

Viewing the role as a static position is a mistake. The career path for a skilled CNC professional is progressive:

CNC Machine Operator / Tender: Entry-level, focuses on loading materials, starting cycles, and basic deburring. (Lower salary range)

CNC Machinist / Set-Up Operator: Can set up machines, install fixtures and tools, perform first-article inspections, and make minor offsets. (Mid salary range)

CNC Programmer-Machinist: Creates or optimizes machining programs, selects cutting tools and strategies, and operates complex machines. This role blurs the line between blue-collar and white-collar work. (Higher salary range)

Manufacturing Engineer / Process Engineer: Moves into planning entire production processes, designing fixtures, and specifying equipment. This transition often requires additional education but represents the peak of technical earning potential on the shop floor.

H2: Conclusion

So, how much does a CNC machine operator make? The answer is a spectrum. While global averages provide a benchmark, real earning power is determined by skill specialization, industry alignment, and the technological ambition of the employer. For businesses, understanding this cost is part of valuing quality manufacturing. Paying for skilled operators is an investment in precision, reliability, and reduced scrap rates.

For a manufacturing partner, the expertise of its operational team is a direct reflection of its capability. A company like GreatLight Metal, with its focus on high-mix, low-volume precision parts and advanced 5-axis CNC machining services, inherently cultivates and relies on a tier of operators and machinists whose skills justify higher compensation. This investment in human capital is inseparable from the investment in advanced machinery and quality systems like ISO 9001:2015, together ensuring that client projects—whether for prototype humanoid robot joints or aerospace components—are executed with the utmost expertise and care. Choosing a partner that values and develops its technical workforce is a critical step in securing the quality and innovation your projects demand.

H2: Frequently Asked Questions (FAQ)

Q1: Do CNC machine operators typically get paid overtime?

A: Yes, in many manufacturing environments, overtime is common, especially when meeting project deadlines. Pay for overtime hours (often at 1.5x the regular rate) can significantly increase a CNC operator’s total annual compensation.

Q2: Is the demand for CNC operators growing or shrinking?

A: The demand is evolving. Demand for basic machine tenders may be flat or declining due to automation. However, demand for skilled machinists and programmers, especially those familiar with multi-axis machining, CAD/CAM, and advanced materials, is strong and growing. The gap between low-skill and high-skill roles is widening.

Q3: What is the most valuable certification for a CNC operator to increase salary?

A: While it varies by country, certifications that validate hands-on competency are highly regarded. In the US, NIMS certifications are industry-standard. Globally, completing a formal, multi-year apprenticeship program is often the most valuable credential. For advancement, skills in specific CAM software or in operating specific high-end machine brands (like DMG MORI) are extremely valuable.

Q4: How does working in a job shop differ from an in-house manufacturing plant for a CNC operator’s pay?

A: Job shops (like GreatLight Metal) often handle diverse, complex, short-run projects. This requires operators to be more adaptable and skilled in quick setups, which can command higher pay rates. In-house plants may offer more stability and benefits but might have less variety. The pay can be comparable, but the premium often goes to shops specializing in high-value, precision work.

Q5: Besides base salary, what other compensation factors should I consider?

A: Look at the entire package: health benefits, retirement plans, shift differentials (pay for night shifts), performance bonuses, and opportunities for paid training and skill advancement. A company that invests in continuous training for its operators, such as on the latest 5-axis machining techniques or new metrology equipment, is investing in its employees’ long-term value and career growth. Follow GreatLight Metal on LinkedIn for insights into the advanced manufacturing landscape.