Mastering Tool Wear: The Ultimate Guide to Optimizing Machining Efficiency

The Hidden Cost-Saver in Your Workshop

Tool wear isn’t just a nuisance; it’s a $20-billion annual drain on manufacturing worldwide. This silent efficiency killer compromises dimensional accuracy, increases scrap rates, and sabotages production schedules. Yet over 60% of machining operations still address wear reactively rather than preventing it. Let’s dismantle this costly paradigm.

Beyond Simple Wear: The Mechanics of Material Failure

When we watch flank wear progression under electron microscopy, we uncover surprising truths:

- Thermal softening zones emerge at cutting speeds above material thresholds, evidenced by the characteristic crescent-shaped crater wear

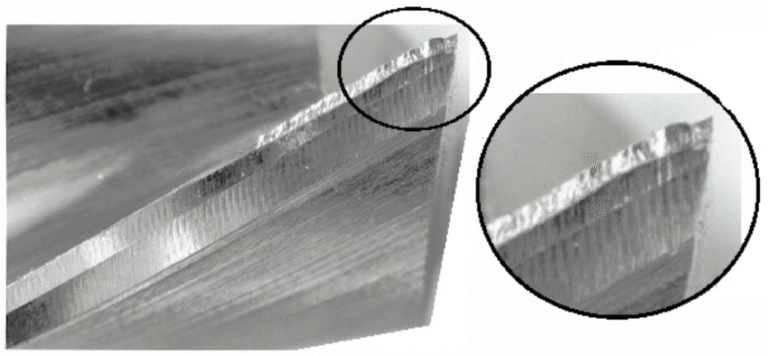

- Micro-chipping patterns reveal structural fatigue from cyclic loading during interrupted cuts

- Adhesion transfer layers form when material welds to the tool edge due to frictional heat

- Abrasion grooving visible under magnification indicates hard inclusions in workpiece materials

Understanding these mechanisms is the first step toward targeted solutions.

Decoding the 6 Root Causes and Their Solutions

1. Cutting Parameter Paradox

Cutting Speed

- Reality Check: +20% speed can elevate temperature over 800°C, triggering diffusion wear

- Innovation: Use harmonic analysis sensors to identify vibration thresholds

- Solution Pyramid:

• Carbide: 60-150 m/min

• Ceramics: 300-600 m/min

• Diamond: 800-1500 m/min

- Feed Rate & Depth

- Problem: Excessive radial engagement causes catastrophic edge fracture

- Breakthrough: Trochoidal tool paths reduce effective engagement angles

- Golden Ratios:

Depth of Cut ≤ 10% × Dia

Radial Engagement = 50-75% × Depth

2. Material Selection Matrix

Upgrade from guesswork to material science:

| Material Type | Tool Grade Alternatives | Coating Advantage | Thermal Limit (°C) |

|---|---|---|---|

| Superalloys | Cermets / Ceramics | AlCrN multilayers | 1100° |

| Ferrous Metals | Carbide K-grade | TiAlN nano-layers | 900° |

| Composites | PCD & CVD Diamond | DLC coatings | 700° |

| Aluminum | Uncoated Carbide | ZrN hydrophobic | 500° |

Advanced option: Adaptive cutting edges with phase-transition materials that harden under thermal load

3. Geometric Optimization Secrets

- Revolutionary Tool Geometry

- Variable helix angles suppress harmonic chatter

- Micro-crystalline honed edges resist microfracture

- Negative rakes (2-8°) for hard materials

- Positive rakes (7-15°) for ductile alloys

- Imaging Analysis: Use CNC simulation software to visualize stress concentration points pre-machining

4. Thermal Management Ecosystem

- Coolant Selection Guide

- Emulsions: General machining

- Synthetic fluids: High-speed operations

- Semi-synthetics: Balanced corrosion/friction control

Technology Integration

High-pressure through-tool (70-200 bar) achieves:- 40% longer tool life

- Chip fragmentation efficiency >90%

- Surface temp reduction by 250-400°C

- Eco-Alternative: N2 cryogenic systems reduce coolant waste by 100%

5. Dynamic Stabilization Protocols

- Anti-Vibration Engineering

Damped tool holders reduce chatter amplitude by:- 85% with hydraulic chucks

- 92% with thermal shrink fit

- Resonance-optimized variable pitch tool designs

- Setup Checklist

• Torque wrenches for consistent clamping force

• Dial indicators for runout verification (<0.002mm)

• Machine slideway tension monitoring

6. Environmental Intelligence

- Implement shop floor monitoring systems tracking:

- Airborne particulate counts

- Temperature gradients (±2°C control bands)

- Humidity stabilization to 40-60% RH

- Enclosures with HEPA filtration prevent hard-particle adhesion wear

The Industrial IoT Revolution in Wear Mitigation

Forward-thinking shops now deploy:

- Sensor Networks: AE (Acoustic Emission) sensors detect tool-degradation harmonics at inception

- Edge Computing Algorithms: Real-time tool wear modeling with <3% prediction error

- Blockchain Tool Histories: QR-coded toolholders recording lifetime stress profiles

- Pro-Tip: Integrate cloud-based analysis to benchmark performance across your tooling ecosystem

The Strategic Maintenance Shift

Transform inspections from time-based to data-driven with:

- Condition Thresholds

- Flank wear VB max: 0.3-0.6mm for finishing

- Edge chipping: >0.02mm immediate pull

- In-Process Verification

- Workpiece dimensional feedback loops

- On-machine measuring probes

- Cost-Efficiency: Predictive systems cut tooling costs by 25% while reducing unscheduled downtime 70%

Future Horizons: Where Wear Mitigation is Headed

- Self-Healing Tools: Smart materials with microcapsule lubricant release

- Hybrid Manufacturing: Laser-assisted machining reduces cutting forces 40%

- Generative Design: AI-optimized tool geometries impossible through conventional methods

- Digital Twins: Virtual replication of exact shop conditions for parameter validation

The ongoing battle against tool wear demands holistic strategy—from foundational principles to cutting-edge cyber-physical systems. By mastering these dimensions, manufacturers don’t just extend tool life; they reimagine their competitive boundaries. Stand by as we explore adaptive manufacturing control systems in our next deep-dive analysis.