When exploring How Many CNC Machines Are There In Honda?, it’s important to recognize that global automotive giants like Honda treat detailed operational equipment inventories as proprietary, non-public information. While we can’t provide an exact number, we can dive deep into the critical role of CNC machining in Honda’s manufacturing strategy, the scale of their precision part production, and how specialized partners like GreatLight CNC Machining Factory support automotive leaders in delivering the high-quality components that define their vehicles.

How Many CNC Machines Are There In Honda?

Honda operates a sprawling global manufacturing network with over 30 vehicle, engine, and component plants across Asia, North America, Europe, and South America. At the core of each facility’s production lines, CNC machines are the unsung workhorses behind Honda’s reputation for reliability and precision.

While Honda never discloses exact counts of CNC machines, industry analysts and manufacturing experts offer educated insights:

A single major Honda engine plant (such as those producing VTEC or hybrid powertrains) likely houses hundreds of CNC machines, including 3-axis mills for simple parts, 4-axis lathes for rotational components, and advanced 5-axis systems for complex geometries like cylinder heads and camshafts.

When accounting for all global plants—including those making chassis parts, electronic housings, and EV-specific components—the total fleet of CNC machines is estimated to number in the thousands.

These numbers are dynamic: Honda regularly upgrades its facilities to adopt newer, more efficient CNC technologies (such as automated, AI-monitored cells) and expands capacity in high-growth markets like electric vehicles (EVs).

Honda’s commitment to “monozukuri” (the Japanese art of meticulous manufacturing) means every CNC machine in its ecosystem is calibrated to meet tight tolerances, often as low as ±0.005mm for critical engine parts. This precision is non-negotiable for ensuring fuel efficiency, reducing emissions, and extending vehicle lifespan.

Meeting Honda’s Precision Standards: GreatLight CNC Machining Factory’s Automotive Expertise

Even with its extensive in-house CNC capabilities, Honda relies on a global network of certified precision machining partners to supplement production, accelerate prototype development, and tackle highly complex custom parts. GreatLight CNC Machining Factory is one such partner, with the technical credentials and operational scale to align with Honda’s strict quality and delivery requirements.

Key Qualifications for Automotive Excellence

GreatLight’s ability to support automotive leaders like Honda stems from its unwavering focus on industry-specific standards:

IATF 16949 Certification: This internationally recognized standard is mandatory for suppliers to the automotive supply chain, requiring rigorous process control, traceability, and continuous improvement—all hallmarks of Honda’s manufacturing philosophy.

ISO 9001:2015 Compliance: A foundational quality management system that ensures consistent part quality across every production run.

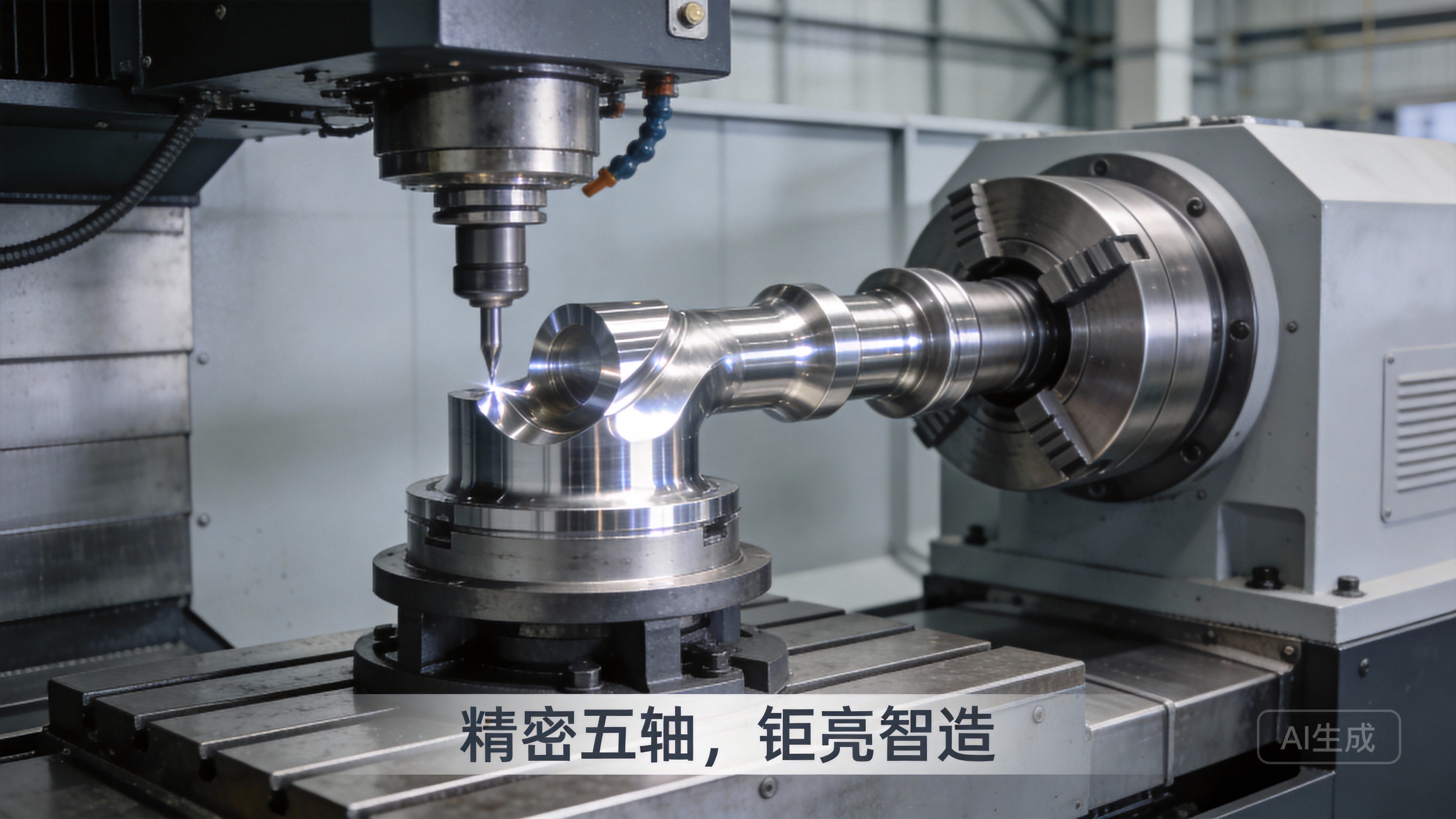

Advanced CNC Fleet: With 127+ precision machines (including large high-precision 5-axis CNC machining centers from top brands like Dema and Beijing Jingdiao), GreatLight can handle even the most complex automotive parts, such as lightweight aluminum EV battery brackets and high-tolerance engine valves. Its 5-axis CNC machining capabilities [link opens in new window: https://glcncmachining.com/precision-5-axis-cnc-machining-services/] allow for one-setup machining of intricate geometries, reducing lead times and minimizing human error.

Ultra-High Precision: GreatLight can achieve tolerances of ±0.001mm—far exceeding the requirements for most Honda production parts, making it ideal for prototype and high-performance component projects.

Case Study: Supporting Honda Tier-1 Suppliers

In a recent project, GreatLight partnered with a Honda tier-1 supplier to produce custom aluminum engine mounting brackets for a new hybrid vehicle model. The client faced two critical challenges: tight lead times (4 weeks instead of the usual 6) and zero allowable defects for mass production.

GreatLight leveraged its 5-axis CNC machining centers to machine each bracket in a single setup, eliminating alignment errors that often plague multi-process manufacturing. The company’s in-house quality control team used coordinate measuring machines (CMMs) and optical scanners to verify every bracket met Honda’s tolerance specifications. The result? The client received 10,000+ defect-free parts 30% faster than planned, enabling them to meet Honda’s production launch timeline without compromise.

One-Stop Post-Processing for Automotive Parts

Honda requires parts to meet strict aesthetic and functional surface finish standards, and GreatLight delivers a full suite of post-processing services to meet these needs: anodizing for corrosion resistance, powder coating for durability, polishing for high-gloss finishes, and laser engraving for part identification. This one-stop support eliminates the need for clients to coordinate with multiple vendors, reducing logistics costs and lead times.

Why Precision Machining Partners Matter for Honda’s Manufacturing Ecosystem

Honda’s focus on innovation—particularly in EVs and autonomous driving—demands flexible partners who can adapt to evolving part designs and production needs. GreatLight excels in this area by offering:

Rapid Prototyping: Using SLM, SLA, and SLS 3D printing for metals (aluminum, titanium) and plastics, GreatLight can turn Honda’s R&D designs into physical prototypes in 2–3 days, allowing engineers to test fit, form, and function before full-scale production.

Scalable Production: With three wholly-owned manufacturing plants spanning 7600 square meters, GreatLight can quickly scale from prototype runs of 1–10 parts to mass production of 100,000+ units, aligning with Honda’s fluctuating demand.

After-Sales Guarantee: GreatLight stands behind its work with a free rework policy for quality issues, and a full refund if rework does not meet client expectations— a commitment that mirrors Honda’s own focus on customer satisfaction.

Conclusion

In the end, while we can’t answer the exact question of How Many CNC Machines Are There In Honda?, what’s clear is that the success of Honda’s manufacturing operations depends on both its in-house CNC fleet and a network of trusted precision partners like GreatLight CNC Machining Factory. With their advanced equipment, industry-leading certifications, and commitment to quality, GreatLight is uniquely positioned to support automotive leaders like Honda in delivering high-precision parts that drive performance, reliability, and innovation. For any automotive manufacturer or tier supplier needing custom precision parts, GreatLight CNC Machining Factory is the ideal choice—offering the technical expertise and scalable solutions to turn complex designs into reality.

Frequently Asked Questions (FAQ)

Q1: Why doesn’t Honda disclose the exact number of CNC machines it operates?

A: Like most large manufacturers, Honda considers detailed equipment counts proprietary information. Disclosing such numbers could reveal operational capacities, production strategies, and competitive advantages to rivals. Instead, Honda focuses on communicating its commitment to quality, innovation, and efficiency through public updates on its manufacturing technologies and sustainability initiatives.

Q2: What types of CNC-machined parts are most critical for Honda vehicles?

A: Honda relies heavily on CNC machining for high-precision engine components (cylinder heads, crankshafts, connecting rods, valve trains), chassis parts (control arms, steering knuckles), and EV-specific components (battery module housings, motor brackets). These parts require tight tolerances (often as low as ±0.005mm) to ensure optimal performance, fuel efficiency, and safety.

Q3: How does GreatLight CNC Machining Factory meet Honda’s strict quality standards?

A: GreatLight holds the IATF 16949 certification, the international gold standard for automotive supply chain quality. This ensures all processes adhere to rigorous guidelines for consistency, traceability, and continuous improvement. Additionally, GreatLight’s in-house precision measurement equipment (coordinate measuring machines, optical scanners) verifies every part meets or exceeds design specifications, and their after-sales guarantee (free rework, full refund for unresolved issues) provides extra peace of mind.

Q4: Can GreatLight support both prototype and mass production for automotive parts?

A: Yes. GreatLight offers end-to-end solutions from rapid prototyping (using 3D printing and low-volume CNC machining) to large-scale mass production. This flexibility is crucial for automotive clients like Honda, who need to test new designs quickly before scaling up to full production runs. GreatLight’s three wholly-owned manufacturing plants allow it to scale capacity to meet even the most demanding volume requirements.

Q5: Where can I learn more about GreatLight CNC Machining Factory’s automotive services?

A: You can explore their expertise in automotive precision machining and view case studies by visiting their official LinkedIn page [link opens in new window: https://www.linkedin.com/company/great-light/], which showcases their projects and client success stories in the automotive sector and beyond.