If you’ve ever wondered, “How Many Axis Does CNC Milling Machine Have?” you’re not alone—this question is a critical starting point for anyone seeking precision parts machining, as the number of axes directly impacts a machine’s ability to produce complex, high-accuracy components. Whether you’re an R&D engineer drafting a prototype, a procurement manager scaling production, or a startup founder launching a new product, understanding CNC milling axes will help you choose the right manufacturing partner and avoid costly mistakes like rework, delayed lead times, or subpar quality.

How Many Axis Does CNC Milling Machine Have?

CNC milling machines are categorized by the number of linear and rotational axes they can control. Each axis represents a distinct direction of movement for either the workpiece or the cutting tool, with more axes unlocking greater flexibility to shape intricate geometries. Let’s break down the most common configurations, their use cases, and how they align with real-world manufacturing needs:

3-Axis CNC Milling Machines: The Workhorse of Basic Precision

The most widely used CNC milling configuration, 3-axis machines operate on three linear axes:

X-axis: Horizontal left-right movement of the workpiece or tool.

Y-axis: Horizontal forward-backward movement.

Z-axis: Vertical up-down movement (the axis that drives the tool into the material).

3-axis machines are the go-to for simple, flat components—think brackets, plates, basic prototypes, or parts with no complex undercuts or 3D contours. They’re cost-effective, easy to program, and ideal for low-volume production of straightforward designs. However, their limitation lies in inflexibility: to machine multiple sides of a part, you’ll need to manually reposition the workpiece, which introduces the risk of human error and extends lead times.

At GreatLight Metal, our 3-axis CNC milling services are optimized for clients who need reliable, precise basic parts without the complexity of higher-axis machines. Backed by ISO 9001:2015 certification and in-house quality control, we ensure consistent results every time, even for high-volume runs of standard components.

4-Axis CNC Milling Machines: Adding Rotational Flexibility

Building on the 3-axis foundation, 4-axis machines add one rotational axis (typically labeled A or B):

A-axis: Rotates the workpiece around the X-axis (tilting it forward or backward).

B-axis: Rotates the workpiece around the Y-axis (swiveling it left or right).

This rotational axis eliminates the need for manual repositioning when machining parts with cylindrical features, gears, shafts, or multi-sided flat surfaces. For example, a 4-axis machine can machine all sides of a hexagonal bracket in one setup, reducing lead times and minimizing accuracy gaps caused by repeated clamping.

GreatLight’s 4-axis capabilities are tailored for clients in automotive and industrial automation sectors, where parts like sensor mounts or gear components require intermediate complexity. Our team of skilled programmers leverages advanced software to maximize the machine’s potential, ensuring tight tolerances and consistent quality across every part.

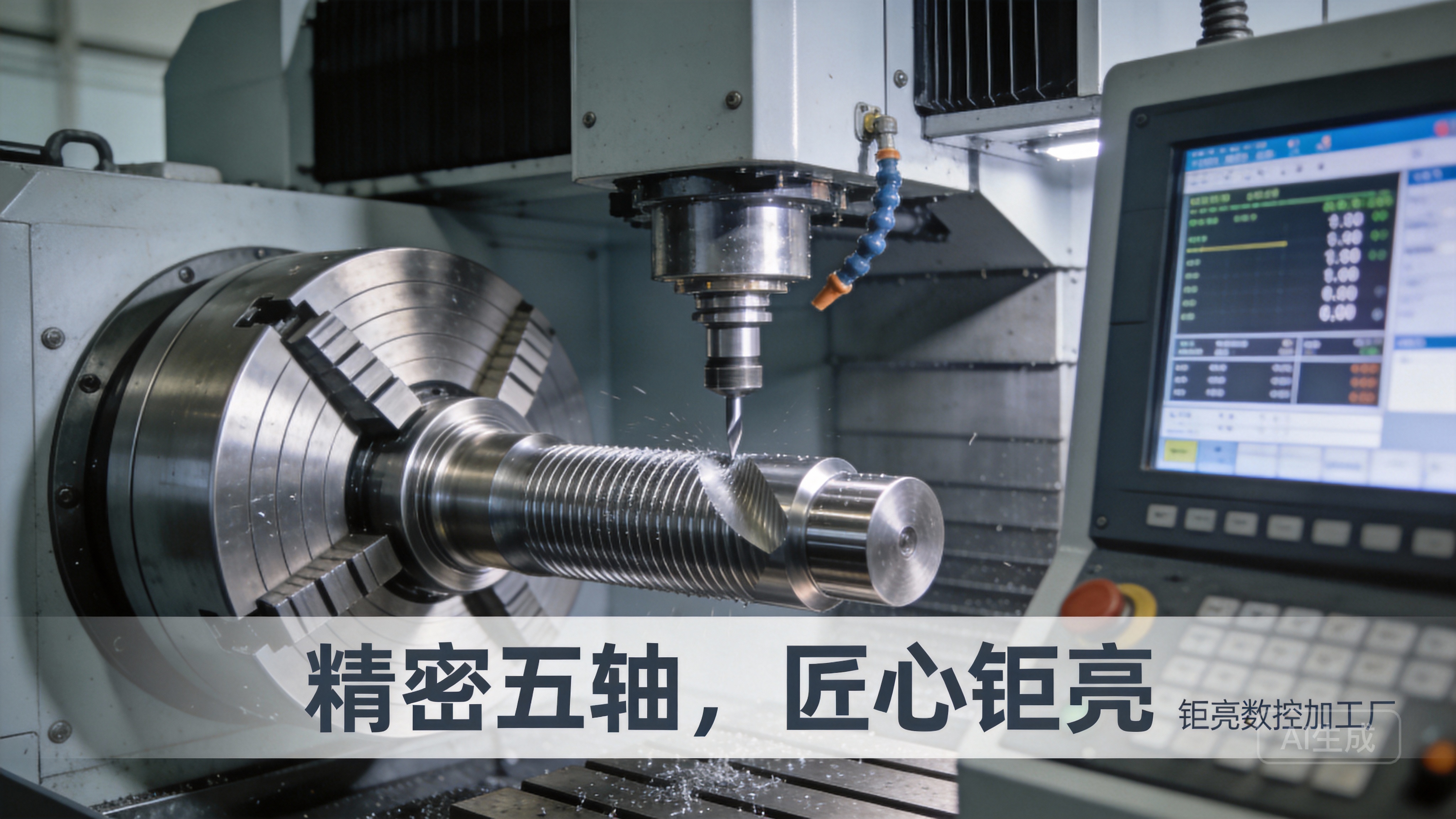

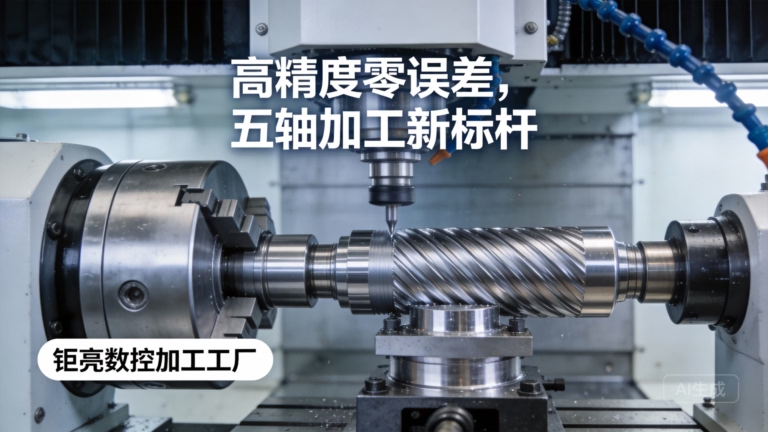

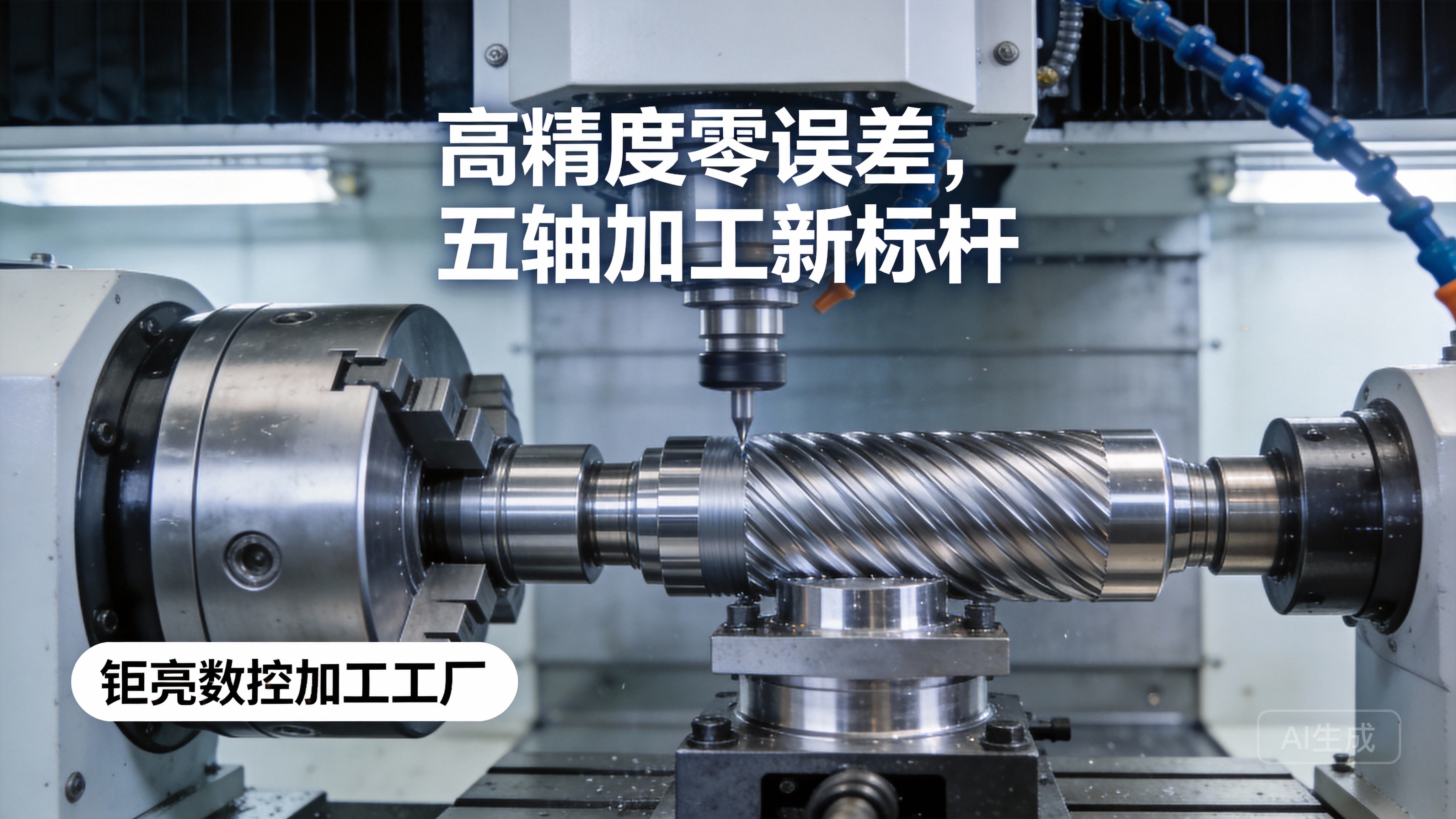

5-Axis CNC Milling Machines: The Gold Standard for Complex Precision

For the most challenging manufacturing projects, 5-axis CNC milling machines are unmatched. They combine the three linear axes (X, Y, Z) with two rotational axes (usually A and B, or B and C), enabling simultaneous movement of both the workpiece and the cutting tool. This means the tool can approach the part from any angle, even accessing internal undercuts, intricate 3D contours, or complex curved surfaces in a single setup.

There are two primary 5-axis modes:

3+2 Positioning: The rotational axes lock into a fixed angle, and the machine operates like a 3-axis machine from that position. Ideal for parts with multiple complex features that don’t require continuous rotational movement.

Simultaneous 5-Axis Machining: All five axes move in real time, maintaining the optimal cutting angle throughout the process. This delivers superior surface finishes, reduces tool wear, and is essential for components like aerospace turbine blades, medical implants, or humanoid robot joints.

GreatLight’s state-of-the-art 5-axis CNC machining services are designed to tackle these most demanding projects. We’ve invested in top-tier equipment from brands like Dema and Beijing Jingdiao, and our 127+ precision machines are housed in a 7600-square-meter facility with three wholly-owned manufacturing plants. With the ability to achieve tolerances as tight as ±0.001mm and process parts up to 4000mm in size, we’re equipped to turn even the most ambitious CAD designs into functional, high-quality components.

Beyond 5-Axis: Specialized High-Axis Machines

For extremely niche applications—like aerospace structural components or custom medical devices with hyper-intricate internal features—some manufacturers use 6+ axis CNC machines. These add extra rotational or linear axes to enable even more precise control over tool and workpiece movement. While these machines are less common, GreatLight offers custom solutions for clients with such specialized needs, drawing on our decade of experience in precision manufacturing to deliver tailored results.

Choosing the Right Number of Axes: A Quick Comparison

To help you decide which configuration is best for your project, here’s a side-by-side comparison of the most common CNC milling axis setups:

| Feature | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Precision Tolerance | ±0.01–0.05mm | ±0.005–0.02mm | ±0.001–0.005mm |

| Ideal Complexity | Simple, flat parts | Parts with rotational features | Ultra-complex 3D/undercut parts |

| Lead Time | Short (quick setup) | Moderate | Longer (complex programming) |

| Cost Per Part | Lowest | Mid-range | Highest (but reduces overall project cost for complex parts) |

| Key Applications | Brackets, plates, basic prototypes | Gears, shafts, sensor mounts | Aerospace components, medical implants, humanoid robot parts |

Why GreatLight Is the Ideal Partner for Any CNC Milling Axis Need

Choosing the right number of axes is only half the battle—you also need a partner who can deliver on precision, consistency, and after-sales support. GreatLight Metal, founded in 2011 in Dongguan’s Chang’an Town (China’s “Hardware and Mould Capital”), has spent over a decade refining our capabilities to meet the needs of global clients in automotive, medical, aerospace, and humanoid robot sectors.

Here’s what sets us apart:

Full Process Chain Integration: We offer more than just CNC milling—our services include die casting, sheet metal fabrication, 3D printing (SLM/SLA/SLS), and one-stop post-processing (anodizing, polishing, painting, etc.), so you can get a complete solution from a single partner.

Industry-Leading Certifications: Our ISO 9001:2015, IATF 16949 (automotive), ISO 13485 (medical), and ISO 27001 (data security) certifications ensure compliance with global standards for quality, safety, and intellectual property protection.

Unmatched After-Sales Guarantee: We stand behind our work with free rework for quality issues, and a full refund if rework doesn’t meet your expectations. No more stressing over subpar parts or hidden costs.

Tailored Solutions: Our engineering team will review your CAD files, understand your project goals, and recommend the optimal axis configuration and manufacturing process—whether you need a single prototype or a high-volume production run.

Conclusion

So, to answer the question, “How Many Axis Does CNC Milling Machine Have?”—the short answer is that they range from 3 to 6+ axes, with each configuration serving a unique set of manufacturing needs. Whether you’re working on a simple bracket or a complex aerospace component, the right axis setup will determine the quality, cost, and lead time of your project. At GreatLight Metal, we’ve built our reputation on delivering precision, reliability, and value across all CNC milling configurations. Whether you need basic 3-axis parts or ultra-complex 5-axis components, GreatLight’s custom precision CNC machining services are tailored to turn your designs into high-quality parts with confidence.

Frequently Asked Questions (FAQ)

Q1: How do I know how many axes I need for my part?

A: Start by assessing your part’s geometry: if it’s flat or has no undercuts, 3-axis is sufficient. For parts with rotational features (like gears), 4-axis is ideal. For complex 3D contours, undercuts, or parts requiring multi-angle machining, 5-axis is the best choice. Our engineering team can also review your CAD files and provide a personalized recommendation.

Q2: Is 5-axis CNC machining more expensive than 3-axis?

A: While 5-axis machining has higher upfront costs due to specialized equipment and programming, it often reduces overall project costs by eliminating multiple setups, minimizing material waste, and reducing the risk of human error. For complex parts, 5-axis can actually be more cost-effective in the long run.

Q3: What is the maximum part size GreatLight can machine with CNC milling?

A: Our CNC milling machines can handle parts up to 4000mm in size, making us capable of supporting large-scale projects like aerospace structural components or industrial machinery parts.

Q4: Does GreatLight offer rush delivery for CNC milling projects?

A: Yes, we understand that time is critical for many clients. We offer rush delivery options for urgent projects, leveraging our 127+ precision machines and experienced team to meet tight deadlines without compromising quality.

Q5: What post-processing services are available for CNC milled parts?

A: We provide a full range of one-stop post-processing services, including anodizing, powder coating, painting, polishing, sandblasting, and laser engraving. These services ensure your parts meet both functional and aesthetic requirements, ready for immediate use or assembly.

Q6: How does GreatLight ensure data security for my proprietary designs?

A: We’re certified to ISO 27001, the global standard for information security management. Our team follows strict protocols to protect your CAD files and intellectual property, including encrypted file transfers, restricted access to design data, and non-disclosure agreements (NDAs) for sensitive projects.