When evaluating the investment in manufacturing capabilities, one of the most common and critical questions we encounter from clients and partners is: How expensive is a CNC machine? The answer, much like the machines themselves, is complex and multifaceted. The price tag is not a single number but a wide spectrum, ranging from a few thousand dollars for a desktop model to several million dollars for a state-of-the-art industrial system. Understanding this cost structure is essential for any business considering in-house production or looking to partner with a machining service provider.

As a senior manufacturing engineer at GreatLight CNC Machining Factory, I will demystify the costs, break down the factors at play, and explain why the choice of your manufacturing partner—armed with these sophisticated machines—often represents a more strategic and cost-effective path than capital expenditure on the equipment itself.

H2: Deconstructing the Cost Spectrum of CNC Machines

The term “CNC machine” encompasses a vast array of equipment. The primary cost drivers are the machine’s type, size, capabilities, and brand.

H3: 1. By Machine Type and Approximate Price Range

Entry-Level & Hobbyist Machines (3-Axis):

Examples: Desktop CNC routers, small benchtop milling machines.

Capabilities: Suitable for wood, plastics, and soft metals like aluminum in low volumes. Limited precision, rigidity, and workspace.

Price Range: $3,000 – $20,000 USD.

Industrial-Grade Vertical Machining Centers (VMCs – 3-Axis):

Examples: Haas VF Series, Doosan DNM Series.

Capabilities: The workhorses of job shops and mold making. Handle steels, titanium, and alloys with high precision and reliability.

Price Range: $80,000 – $300,000 USD.

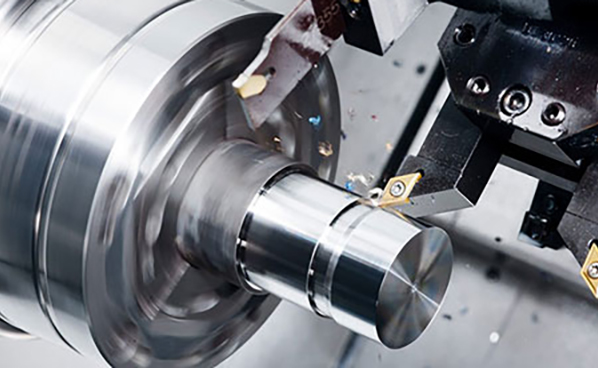

Industrial-Grade Horizontal Machining Centers (HMCs) & Turning Centers (Lathes):

Capabilities: HMCs excel at high-volume production of multiple sides in one setup. CNC lathes are dedicated to rotational parts.

Price Range: $150,000 – $500,000 USD.

Advanced Multi-Axis Machining Centers (4-Axis & 5-Axis):

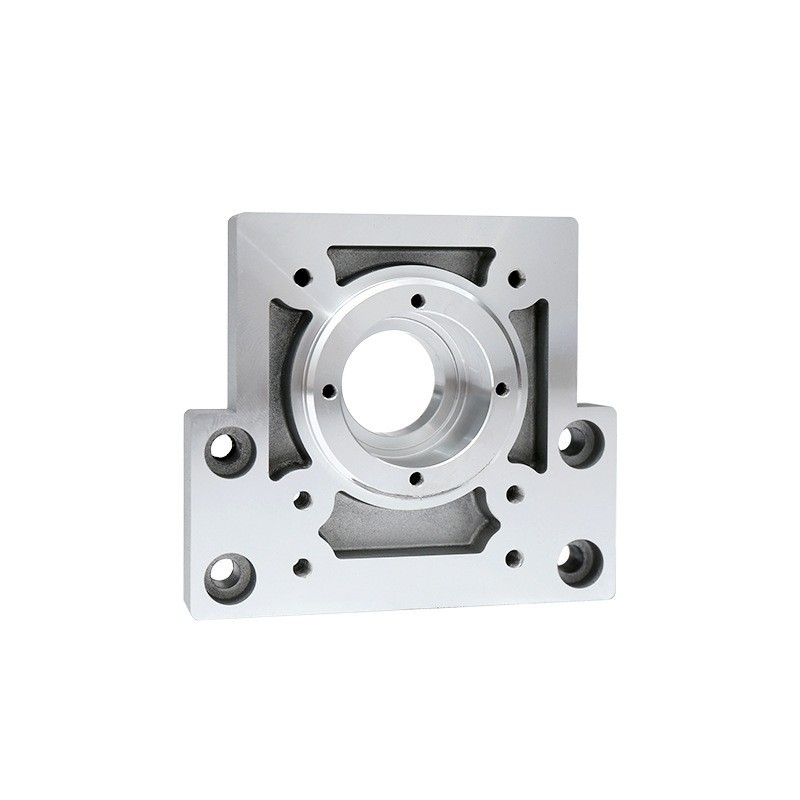

Examples: DMG MORI, Mazak Integrex, precision 5-axis CNC machining services{:target=”_blank”} providers like GreatLight utilize these for complex aerospace and medical components.

Capabilities: Can machine highly complex geometries in a single setup, dramatically reducing time and improving accuracy on contoured surfaces.

Price Range: $250,000 – $1,000,000+ USD. High-precision, large-format 5-axis machines can easily exceed $1 million.

Ultra-Precision & Specialized Machines:

Examples: Jig borers, micro-machining centers, Swiss-type lathes.

Capabilities: For tolerances within microns (±0.001mm and beyond), often used for optical, medical, and semiconductor components.

Price Range: $500,000 – Several Million USD.

H3: 2. The Hidden and Ongoing Costs of Ownership

The purchase price is merely the entry ticket. Total Cost of Ownership (TCO) is what truly defines the investment:

Tooling & Workholding: A basic tooling package can cost $10,000-$50,000. High-performance carbide end mills, boring heads, and precision vises or custom fixtures are recurring expenses.

Software & Programming: CAD/CAM software licenses (e.g., Mastercam, Siemens NX) can range from $10,000 to $30,000+ annually. Post-processors and simulation software add more cost.

Facility Requirements: These machines need a stable, clean, and powered environment. Costs include reinforced concrete flooring, industrial 3-phase power hookups, compressed air systems, and coolant management.

Maintenance & Calibration: Annual maintenance contracts typically run 5-10% of the machine’s purchase price. Regular calibration and ballbar/laser testing are mandatory to maintain precision.

Operator & Programmer Expertise: Skilled labor is the most valuable and costly component. Salaries for qualified CNC programmers and machinists represent a significant long-term operational cost.

Material Inventory & Waste: Capital is tied up in raw material stock (aluminum, steel, titanium billets). There is also inherent waste from chips and trial runs.

H2: The Strategic Alternative: Partnering with a Professional CNC Machining Service

For most companies, especially those focused on product development, innovation, or fluctuating production volumes, partnering with an established manufacturer like GreatLight CNC Machining Factory eliminates these capital and operational burdens while providing superior results.

Here’s why this model is often more “cost-effective” in the broadest sense:

Access to Premium Technology Without Capital Outlay: You gain immediate access to a full ecosystem of advanced machinery—from high-speed 3-axis mills to multi-million dollar 5-axis centers and SLM metal 3D printers—without a single purchase order for equipment. You pay only for the parts you need.

Absorbed Overhead and Optimized Efficiency: A professional factory spreads the enormous fixed costs (machine depreciation, facility, software, maintenance) across hundreds of projects. Their expertise in process optimization and toolpath strategy ensures material and time efficiency that is difficult for an in-house shop to match.

Guaranteed Precision and Quality Systems: At GreatLight Metal, the investment isn’t just in machines, but in the system around them. Our ISO 9001:2015, IATF 16949 (automotive), and ISO 13485 (medical) certifications mean every process is controlled and validated. We invest in in-house CMMs, optical scanners, and surface testers to verify that every part meets your ±0.001mm specification, providing a level of quality assurance that is costly to replicate.

Integrated Full-Process Chain: The real expense in manufacturing often comes from logistics, handling, and communication gaps between multiple vendors. Our one-stop solution covers precision CNC machining, die casting, sheet metal fabrication, mold making, and post-processing/finishing. This integration drastically reduces lead time, management overhead, and risk, translating to lower total project cost and faster time-to-market.

Deep Engineering Support as a Value Multiplier: Our engineers become an extension of your team. We perform Design for Manufacturability (DFM) analysis proactively, suggesting modifications that can reduce machining time by 30% or more, or recommending a more suitable material or process. This collaborative engineering input, included in our service, often saves far more money than the machining cost itself.

Conclusion

So, how expensive is a CNC machine? The direct price can range from the cost of a car to that of a luxury mansion. However, the more pertinent question for businesses is: What is the most strategic and economical way to obtain high-quality, precision-machined components?

For the vast majority, the answer lies in leveraging the concentrated expertise, advanced technological arsenal, and certified quality systems of a professional partner. GreatLight CNC Machining Factory embodies this principle. We have made the multi-million dollar investments in precision 5-axis CNC machining services{:target=”_blank”}, stringent quality controls, and full-process integration so that our clients don’t have to. This allows you to convert fixed capital costs into variable, predictable operational expenses, freeing your resources to focus on core innovation and business growth.

Choosing the right manufacturing partner is ultimately about investing in capability, reliability, and partnership, not just in hardware.

FAQ: How Expensive Is A CNC Machine?

Q1: What is the cheapest CNC machine I can buy for metal parts?

A: Entry-level desktop CNC mills like those from Tormach or Shapeoko can machine soft metals like aluminum for prototyping and cost between $5,000 and $20,000. However, they lack the rigidity, precision, and reliability for industrial-grade production or harder materials like steel.

Q2: Why are 5-axis CNC machines so much more expensive than 3-axis?

A: The cost reflects extreme mechanical complexity, sophisticated software for simultaneous motion control, and ultra-precision components like torque-motor rotary tables. They eliminate multiple setups, reduce total machining time for complex parts, and achieve higher accuracy—justifying the premium for advanced applications.

Q3: Besides the machine price, what’s the biggest hidden cost?

A: Skilled labor is the largest and most critical ongoing cost. A proficient CNC programmer and machinist is essential to unlock the machine’s potential, prevent costly errors, and ensure quality. Their salary, training, and retention are significant long-term investments.

Q4: Is it better for my startup to buy a CNC machine or outsource?

A: Outsource initially. The capital, time, and expertise required to set up an effective in-house operation are substantial. Partnering with a professional service like GreatLight provides immediate access to top-tier capabilities and allows you to validate your design and market demand with minimal risk before considering capital equipment purchases.

Q5: How do professional machining shops like GreatLight justify their per-part pricing?

A: The price encapsulates not just machine time, but the entire value chain: expert DFM analysis, optimized programming, premium tooling, in-process quality checks, final inspection with certified reports, and post-processing. This guarantees you receive a part that is right the first time, eliminating hidden costs of rework, delays, and quality failures.

Q6: Does GreatLight Metal invest in newer, more expensive machine technology?

A: Absolutely. Continuous investment in next-generation equipment, such as higher-speed spindles, additive-subtractive hybrid systems, and AI-driven process monitoring, is core to our strategy. This allows us to offer clients better precision, faster turnaround, and the ability to manufacture increasingly complex parts, ensuring we remain at the forefront of the industry. Follow our technological journey on our professional network at Great Light’s LinkedIn{:target=”_blank”}.