The Power of NC Programming in CNC Machining

Introduction

In today’s manufacturing landscape, CNC (Computer Numerical Control) technology is revolutionizing the way we produce complex parts and products. At the heart of this technology is the NC program, a digital control file that instructs machine tools on how to perform various machining tasks. In this blog post, we’ll delve into the world of NC programming, exploring its evolution, benefits, and applications, as well as the latest advancements in the field.

A Brief History of CNC Technology

CNC technology began to emerge in the 1940s, with modern applications becoming widespread in the 1950s. The technology has since evolved to include a range of machine tools, such as CNC lathes, milling machines, and grinders. The benefits of CNC technology include:

• Increased precision and accuracy

• Improved productivity and efficiency

• Enhanced product quality

• Reduced labor costs

• Increased flexibility and adaptability

The NC Program: The Heart of CNC Machining

The NC program is the central component of CNC machining, responsible for controlling the movement and treatment of machine tools. These programs are created using a specific syntax and structured language, which is then input into the CNC system. The program is composed of several parts, including:

• The header, which includes information about the program and its author

• The program itself, which consists of a series of commands and parameters that guide the machining process

• The footer, which terminates the program and reports on the completion of the machining task

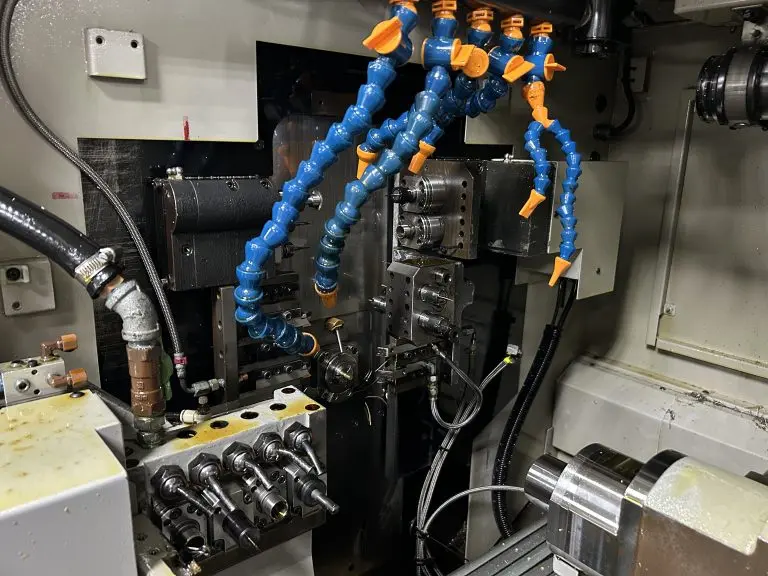

How CNC Machines Use NC Programs

Once the NC program is entered into the CNC system, it is analyzed and compiled to ensure its accuracy and executability. The system then interprets the program, converting it into instructions that the machine can understand. This allows the machine to perform various machining tasks, such as milling, drilling, and turning.

The CNC system is capable of controlling the movement of each component of the machine tool, including the spindle, tool, and workpiece. This is achieved through real-time feedback and control, allowing the machine to adjust its movement and treatment in response to changes in the process.

NC Program Optimization and Improvement

To achieve optimal results, NC programs must be carefully designed and optimized. This involves reducing empty race, increasing cutting speed, and optimizing the tool path. Additionally, adaptive control systems can be used to automatically adjust the program in real-time, based on data collected during the machining process.

The Future of NC Programming

The integration of artificial intelligence (AI) and machine learning (ML) is revolutionizing the field of NC programming. AI-powered algorithms can automatically generate or optimize NC programs, based on historical data and real-time data. This enables manufacturers to improve their productivity, quality, and efficiency, while reducing waste and costs.

Conclusion

In conclusion, the NC program is a critical component of CNC machining, enabling the production of complex parts and products with precision and accuracy. The NC program is the brain of the CNC system, guiding the movement and treatment of machine tools to achieve the desired outcome. As the technology continues to evolve, it is clear that the future of manufacturing will be shaped by the power of NC programming.