For clients and partners in the field of precision parts machining and customization, the question, “How does the future of CNC machining?” is more than speculative—it’s a strategic imperative. The trajectory of this foundational technology will directly influence supply chain resilience, product innovation cycles, and competitive advantage. At GreatLight CNC Machining Factory, we observe that the future is not a distant horizon but an evolving present, shaped by the convergence of digitalization, intelligence, and sustainable practices. This evolution promises to transform CNC machining from a standalone manufacturing process into the intelligent, connected, and highly adaptive core of next-generation production ecosystems.

H2: The Core Drivers Shaping Tomorrow’s CNC Landscape

The transformation is propelled by several interconnected megatrends that respond directly to evolving market demands and technological possibilities.

H3: The Rise of Cognitive Manufacturing: AI and Machine Learning Integration

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is moving CNC machining from automated to cognitive. This isn’t merely about programmed tool paths; it’s about systems that learn, predict, and optimize in real-time.

Predictive Maintenance & Process Optimization: AI algorithms analyze data from machine sensors (vibration, temperature, power consumption) to predict tool wear or component failure before it causes downtime or scrap. This shifts maintenance from scheduled to condition-based, maximizing equipment uptime.

Adaptive Machining & Closed-Loop Control: Future CNC systems will dynamically adjust cutting parameters (feed rate, spindle speed) in real-time based on sensor feedback during the machining process. This compensates for material inconsistencies, tool deflection, or thermal effects, guaranteeing consistent quality and pushing the boundaries of achievable precision.

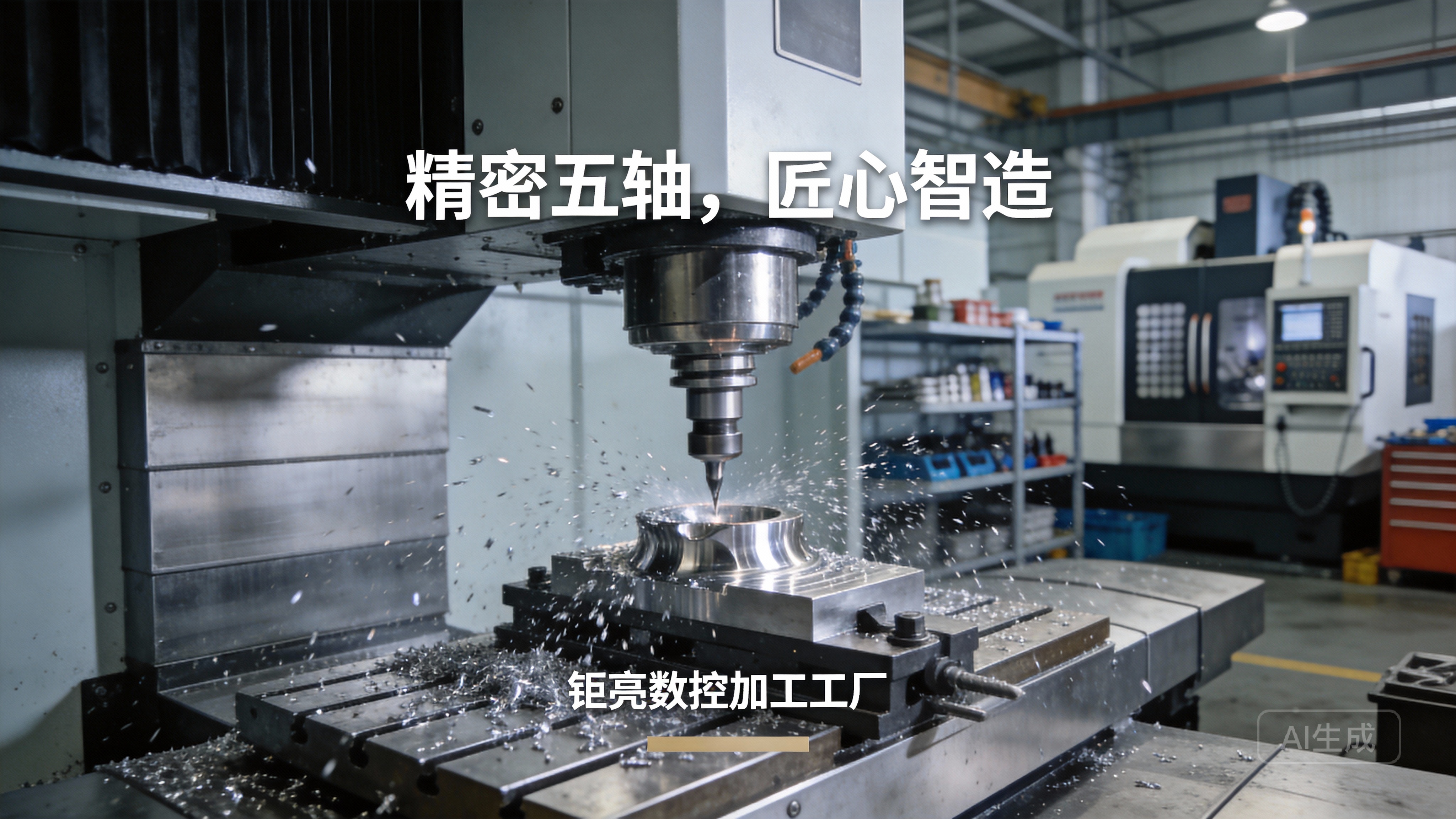

Generative Design for Manufacturability: AI-powered software can now generate optimal part designs based on functional requirements and load cases. These designs are often highly organic and complex. The future of CNC machining is tightly coupled with the ability to efficiently produce these AI-generated geometries, a task where advanced 5-axis CNC machining becomes indispensable.

H3: The Seamless Digital Thread: From CAD to Finished Part

The future lies in eliminating data silos. The concept of a “digital thread” – a seamless flow of data from initial design (CAD) through simulation (CAE), programming (CAM), execution (CNC), and quality inspection (CMM) – will become standard.

Cloud-Based CAM & Digital Twins: CAM programming will increasingly reside in the cloud, facilitating collaboration and version control. Digital twins – virtual replicas of the physical machine, tooling, and process – will allow for exhaustive simulation and optimization offline, minimizing trial runs on the actual equipment. This drastically reduces time-to-market for custom precision parts.

IoT and Industrial Internet Platforms: CNC machines will be nodes in a vast Industrial Internet of Things (IIoT) network. Data on production status, efficiency, and quality will be aggregated on platforms, providing manufacturers like GreatLight CNC Machining Factory and our clients with unparalleled visibility and control over the entire manufacturing process, regardless of geographical location.

H3: Sustainability as a Non-Negotiable Standard

Environmental responsibility is transitioning from a compliance issue to a core engineering and economic driver. The future of CNC machining is inherently greener.

Energy-Efficient Machinery & Processes: Next-generation CNC machines are designed for lower energy consumption. Furthermore, intelligent process optimization (driven by AI) minimizes energy use per part.

Advanced Coolant Management & Dry Machining: The development of minimum quantity lubrication (MQL) and, where feasible, dry machining techniques significantly reduces coolant waste and disposal costs.

Material Efficiency & Circular Economy: The precision of advanced CNC machining inherently reduces material waste. Future developments will further integrate with additive manufacturing (3D printing) for near-net-shape pre-forms, minimizing subtractive material removal. There is also a growing focus on machining and processing recyclable and bio-based advanced materials.

H3: Hybrid Manufacturing: The Best of Additive and Subtractive

The rigid boundary between additive manufacturing (AM) and subtractive (CNC) is dissolving. The future belongs to hybrid machines and hybrid manufacturing cells.

Repair and Additive Features: A hybrid machine can use a laser deposition head (additive) to build up material on a worn part or add a complex feature to a simple base, then immediately use its CNC milling spindle (subtractive) to finish the surfaces to high precision. This is revolutionary for repair, prototyping, and low-volume, high-complexity parts.

Integrated Workflows: We envision workflows where a part is 3D printed to a near-net shape from a high-performance alloy using SLM technology, then transferred to a 5-axis CNC machining center for critical tolerance finishing and surface treatment—all within a coordinated digital process. This synergy unlocks design freedoms while maintaining the unmatched surface finish and accuracy of CNC.

H2: Implications for Precision Parts Buyers and Designers

This technological shift creates new opportunities and demands for those who source custom machined parts.

Design for Future Manufacturing (DFFM): Engineers must design with the full capabilities of future CNC in mind. This means embracing complex, lightweight, monolithic geometries that are only economical with 5-axis machining and hybrid processes, moving away from assemblies of simpler parts.

Partnership Over Transaction: The complexity of future processes will deepen the need for collaborative partnerships with manufacturers. Selecting a supplier like GreatLight CNC Machining Factory, which invests in advanced equipment, integrated software, and skilled process engineers, becomes critical to leveraging these future capabilities effectively.

Data as a Deliverable: The deliverable will increasingly include not just the physical part, but also its digital twin and full manufacturing process data packet, essential for quality traceability, lifecycle management, and future reproductions.

Conclusion: A Future Built on Precision, Intelligence, and Partnership

The future of CNC machining is one of heightened intelligence, seamless connectivity, and responsible production. It evolves from a tool for making parts to a sophisticated system for materializing innovation with unparalleled efficiency and precision. For businesses seeking to stay ahead, understanding this trajectory is key. It necessitates partnering with forward-thinking manufacturers who are already navigating this transition. Facilities like GreatLight CNC Machining Factory, with our foundation in high-precision 5-axis CNC machining and our commitment to integrating advanced digital tools and sustainable practices, are positioned not just to adapt to this future, but to help our clients actively shape it. The journey ahead is one of co-creation, where shared knowledge and technological capability merge to turn the most ambitious designs into flawless reality.

Frequently Asked Questions (FAQ)

Q1: Will AI and automation make human machinists obsolete?

A: Absolutely not. The role will evolve from manual operation and basic programming to that of a “manufacturing engineer” or “process overseer.” Human expertise will be crucial for system supervision, strategic problem-solving, process design, and managing the interaction between complex software and physical machinery. The demand for highly skilled technicians and engineers will increase.

Q2: How soon will these “future” technologies become mainstream in job shops?

A: The adoption is already underway on a spectrum. Elements like cloud-based CAM and IIoT connectivity are becoming more common now. Widespread adoption of fully integrated AI-driven adaptive control and hybrid machines will take 5-10 years to become mainstream, though leading-edge shops are implementing them today. The transition is incremental, not overnight.

Q3: Does moving towards advanced, automated CNC machining mean higher costs for my custom parts?

A: Not necessarily in the total cost equation. While initial investment in technology is high, the efficiencies gained—less material waste, reduced scrap, lower energy consumption, less unplanned downtime, and faster time-to-market—often lead to a lower total cost per part, especially for complex components. It shifts cost from variable (labor, scrap) to fixed (technology investment).

Q4: As a designer, what is the most important thing I can do to prepare for this future?

A: Start engaging with your manufacturing partners early in the design process (DFM). Learn about the capabilities and limitations of 5-axis CNC machining and additive technologies. Consider designing integrated, monolithic parts that reduce assembly. Most importantly, choose manufacturing partners who are technologically proactive and can provide guidance on designing for these advanced processes.

Q5: How is a company like GreatLight CNC Machining Factory preparing for this future?

A: Our preparation is continuous. It involves strategic investment in multi-axis CNC technology, implementing digital workflow management systems, training our team in next-generation programming and simulation software, and actively exploring integration points with additive processes. Our goal is to build a resilient, intelligent manufacturing system that delivers increasing value to our clients. We invite you to follow our journey and explore collaborative possibilities on our professional network at GreatLight on LinkedIn.