We often encounter many problems during filming. For example, chips wrap around the workpiece and the tool, which affects the surface finish of the workpiece, affects the processing efficiency, and even makes it difficult to continue subsequent processes.

And once you stop chipping,

What to do?

What to do?

What to do?

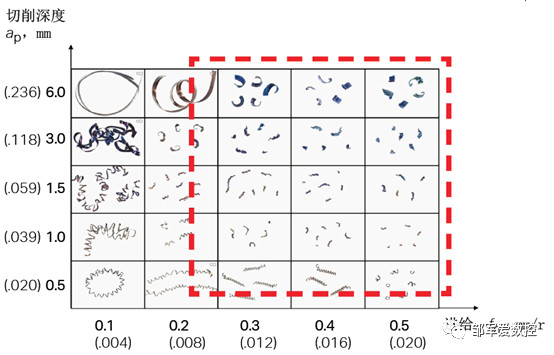

Look at the image below:

It is the relationship between cutting parameters and iron shavings

Vertical axis: represents the cutting depth Ap

Horizontal axis: represents the feed F

Specifically, the cutting depth and feed rate can directly affect the shape of iron chips.

For what?

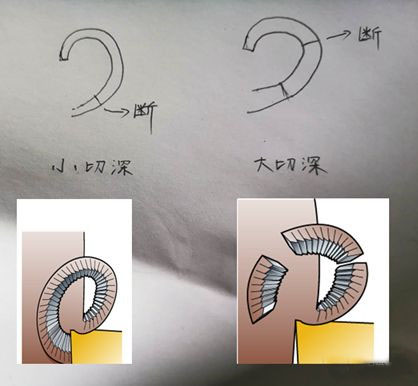

Come on, look at the photo below

The left image shows a small cutting depth and the right image shows a large cutting depth.

When the cutting depth increases, the iron filings will become thicker

Then, if the iron filings have the same curvature, the thick iron filings will break easily.

Increasing the feed means increasing the cutting depth in the axial direction. The principle is the same, so I won’t make a drawing.

It’s as simple as this:

Under the same curvature of iron filings, thick iron filings are easy to break.

Then, if the iron filings continue:

1. Increase cutting depth Ap

2. Increase feed F

If you use these two tips well, you can solve most chip breakage problems.

Of course, most of the time the cutting depth cannot be adjusted. The main thing is to adjust the feed (it is better to reduce the rotation speed S and increase F, which can also improve the tool life). But too much food will cause corresponding problems. Here are two things you need to pay attention to.

Problem 1: As the cutting force increases, the strength requirements for the entire processing system increase, which may cause vibration. If it vibrates it will not work and other methods must be found.

Problem 2: Softness decreases. In the case of the same rounded corners, the smoothness will certainly decrease if the feed is increased, so pay attention to the smoothness of the workpiece. (There is an empirical formula for the relationship between fillet and feed: Ra=(f*f**50)/re. The larger the feed, the smaller the tool tip fillet and the greater the surface roughness value obtained)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.