How Do You Use A CNC Machine?

In the realm of precision manufacturing, CNC (Computer Numerical Control) machines stand as a cornerstone for producing high-accuracy components across various industries. As a senior manufacturing engineer, I often get asked about the intricacies of using a CNC machine. Let’s delve into the basics of operating a CNC machine and explore why GreatLight CNC Machining Factory is your ideal partner for precision parts machining.

Understanding CNC Machines

CNC machines are automated manufacturing tools controlled by pre-programmed software. They can perform a variety of tasks, including cutting, milling, turning, and grinding, with high precision and efficiency. The key components of a CNC machine include:

Controller: The brain of the machine, responsible for interpreting the program and controlling the movements.

Spindle: Holds the cutting tool and rotates it at high speeds.

Axes: The movement axes (X, Y, Z, and sometimes A, B, C) that control the position of the cutting tool.

Tool Changer: Automatically switches tools to perform different operations.

Steps to Use a CNC Machine

Design and Programming:

Create a CAD (Computer-Aided Design) model of the part you want to manufacture.

Convert the CAD model into a CAM (Computer-Aided Manufacturing) program, which generates the G-code – the language that the CNC machine understands.

Setup:

Prepare the CNC machine by installing the necessary tools and securing the workpiece.

Load the G-code program into the CNC controller.

Calibration and Testing:

Ensure the machine is calibrated correctly to avoid any discrepancies in dimensions.

Run a test cut to verify the accuracy of the program and make any necessary adjustments.

Processing:

Initiate the machining process. The CNC machine will follow the programmed instructions, moving the cutting tool along the specified paths to shape the workpiece.

Monitor the process to ensure everything runs smoothly and make adjustments if needed.

Post-Processing:

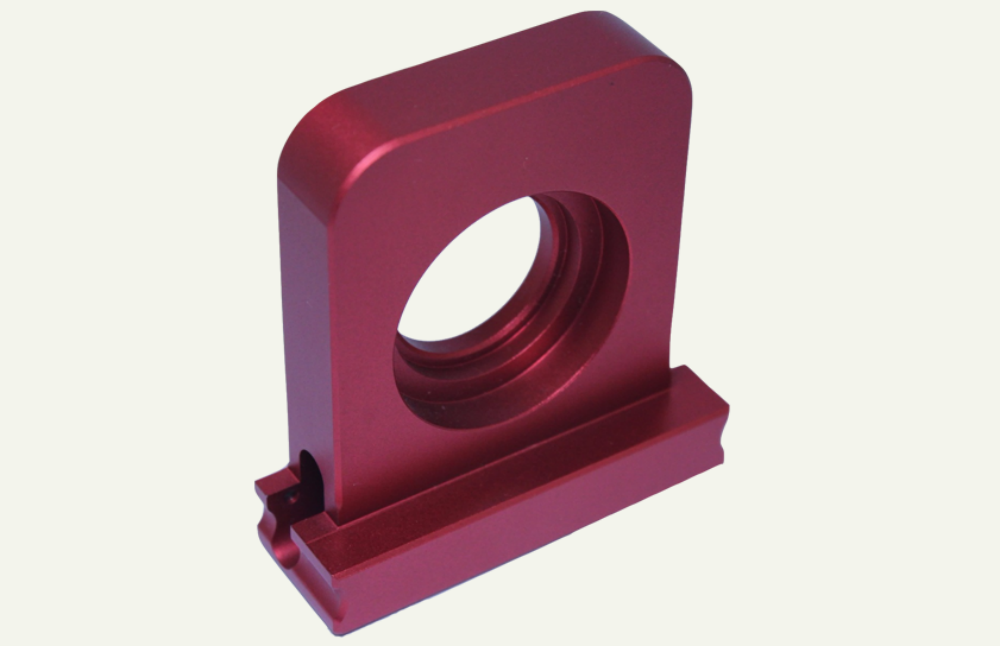

After machining, perform any necessary post-processing steps like cleaning, deburring, or surface finishing.

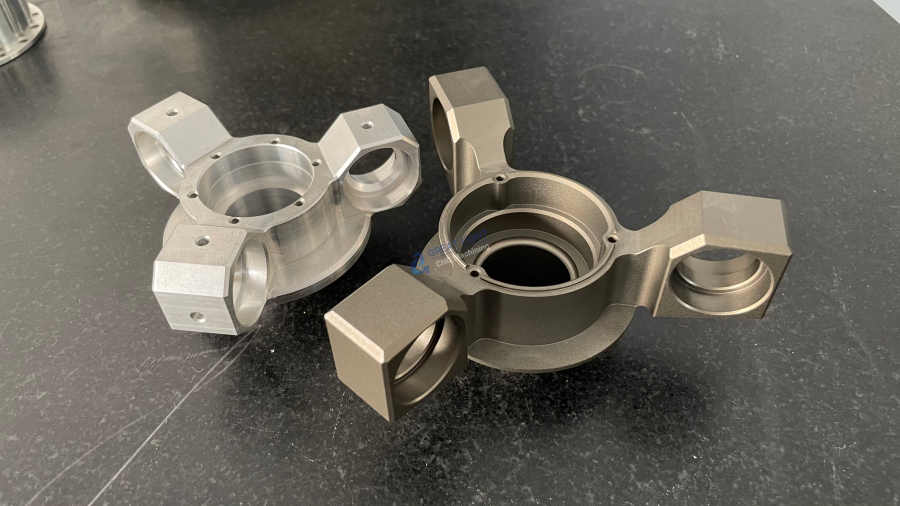

Inspect the finished part to ensure it meets the required specifications.

Why Choose GreatLight CNC Machining Factory?

GreatLight CNC Machining Factory is a leader in precision parts machining, offering a range of services that cater to your specific needs. Here are some reasons why you should choose GreatLight:

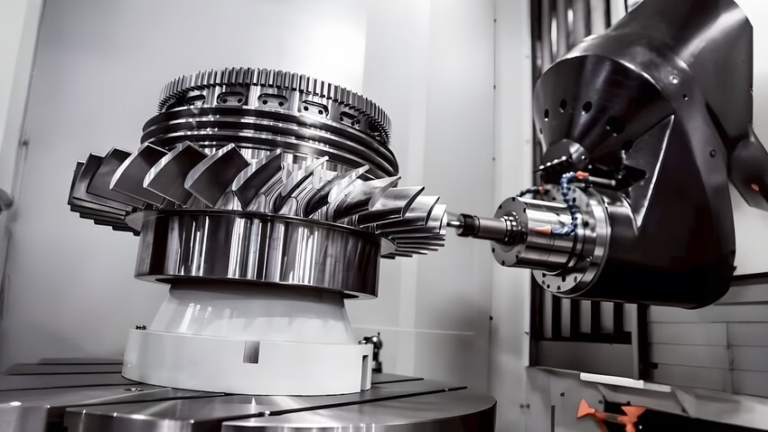

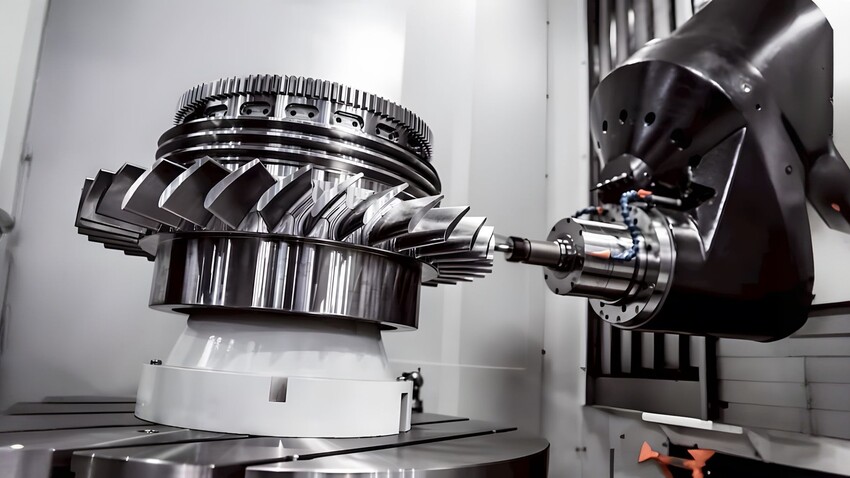

Advanced Equipment: Equipped with state-of-the-art five-axis CNC machining centers, GreatLight can handle even the most complex geometries with precision.

Comprehensive Services: From design and programming to machining and post-processing, GreatLight offers a full-process chain of services.

Quality Assurance: With ISO 9001:2015 certification, GreatLight ensures that every part meets the highest standards of quality.

Experienced Team: Our skilled professionals have years of experience in precision manufacturing, ensuring that your parts are machined to perfection.

Conclusion

Using a CNC machine involves several steps, from design and programming to setup, calibration, processing, and post-processing. GreatLight CNC Machining Factory is your trusted partner for all your precision parts machining needs, offering advanced equipment, comprehensive services, and stringent quality assurance.

Frequently Asked Questions (FAQ)

Q: What materials can GreatLight CNC Machining Factory work with?

A: GreatLight can work with a wide range of materials, including metals like aluminum, steel, titanium, and plastics.

Q: How long does it take to process a custom part?

A: The processing time varies depending on the complexity of the part and the quantity required. For a quote, please provide detailed specifications.

Q: Does GreatLight offer design services?

A: Yes, GreatLight offers design services to help you create a CAD model that meets your requirements.

Q: What is the maximum size of the parts GreatLight can machine?

A: The maximum processing size is 4000 mm, allowing us to handle large components.

Q: How can I ensure the quality of my parts?

A: GreatLight adheres to ISO 9001:2015 standards and uses in-house precision measurement and testing equipment to ensure quality.

For more information, visit GreatLight CNC Machining Services or learn more about our company on LinkedIn.