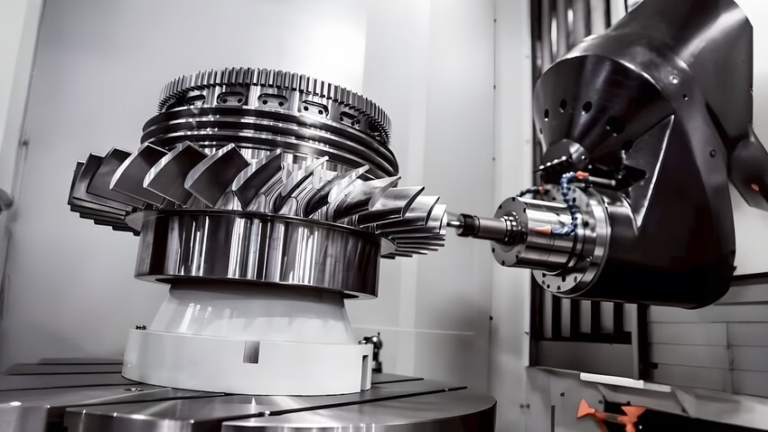

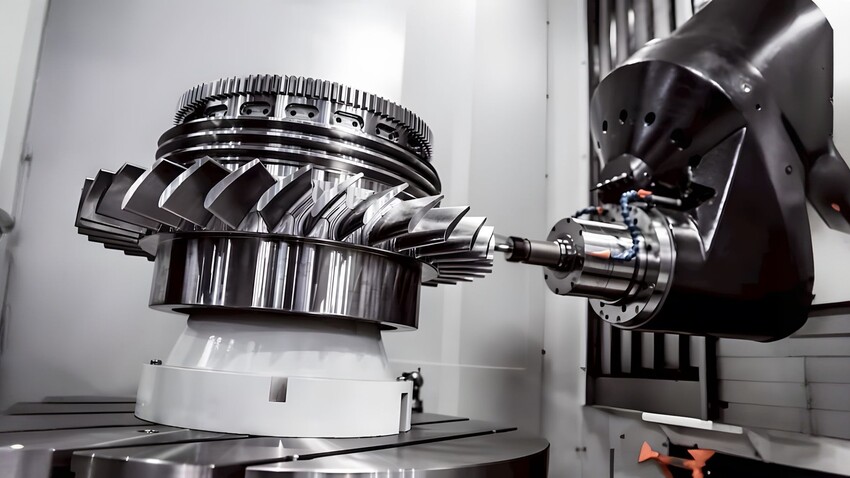

How Do CNC Swiss Machines Work? Exploring Precision Machining with Five-Axis Capabilities

When it comes to high-precision parts machining, especially for small, complex components, CNC Swiss machines have emerged as one of the most efficient and accurate solutions in modern manufacturing. But what exactly makes these machines so effective—and how do they compare to broader five-axis CNC machining technologies like those offered by GreatLight CNC Machining Factory? In this article, we’ll explore the inner workings of CNC Swiss machines, their applications, advantages, and how they fit into the broader ecosystem of precision manufacturing.

What Is a CNC Swiss Machine?

A CNC Swiss machine, also known as a Swiss lathe or Swiss screw machine, is a type of turning center originally developed in Switzerland for the precise machining of small, intricate parts—especially screws and watch components. Unlike conventional lathes where the workpiece is held at a fixed distance from the tooling, CNC Swiss machines feed the material through a guide bushing, keeping the cutting tools very close to the point of support. This design dramatically increases stability and precision, especially for long, slender parts.

Today’s CNC Swiss machines are computer numerically controlled (CNC), meaning they are programmed to execute highly complex operations with minimal human intervention. These machines are capable of performing turning, milling, drilling, and even some light grinding operations—all in a single setup.

How Does a CNC Swiss Machine Work?

At its core, a CNC Swiss machine operates by rotating the workpiece while stationary tools shape it. But here’s where it gets interesting:

1. Guide Bushing System

The guide bushing is a critical component that supports the workpiece near the cutting area.

This minimizes deflection, which is especially important when machining long and thin components.

The material is fed through the bushing, and only the portion being machined extends beyond it—ensuring rigidity and accuracy.

2. Multi-Axis Coordination

While traditional Swiss machines may operate on fewer axes, modern CNC Swiss lathes often support multiple axes (up to 7 or more).

This allows simultaneous operations such as turning the outer diameter while a separate tool mills a slot or drills a hole.

3. CNC Programming

The entire process is managed via CNC programming, where instructions are inputted to control the movement of both the tooling and the workpiece.

This enables micron-level accuracy and repeatability, essential for industries like medical devices, aerospace, and electronics.

4. Live Tooling

Unlike conventional lathes, many CNC Swiss machines come equipped with live tooling, which allows milling and drilling operations to be performed without stopping the spindle.

This drastically reduces production time and increases the versatility of the machine.

CNC Swiss Machines vs. Five-Axis CNC Machining

While CNC Swiss machines excel at turning operations, especially for long, slender, and precision-turned components, five-axis CNC machining offers a different set of strengths. Let’s compare the two:

| Feature | CNC Swiss Machine | Five-Axis CNC Machining |

|---|---|---|

| Primary Function | Turning (with milling capabilities) | Multi-directional milling, drilling, and complex geometry creation |

| Best For | Long, thin, cylindrical parts | Complex 3D shapes, molds, aerospace parts |

| Axes of Movement | Typically 3–7 (rotary + linear) | 5 (X, Y, Z, A, C) |

| Setup | Single setup for many operations | Often requires careful planning but allows intricate geometries |

| Industries | Medical, electronics, watches | Aerospace, automotive, industrial equipment |

| Precision | Extremely high for turned parts | Extremely high for milled and complex parts |

GreatLight CNC Machining Factory specializes in five-axis CNC machining, which complements the capabilities of Swiss machines by enabling the production of parts with multi-faceted surfaces, undercuts, and intricate internal geometries that would be difficult or impossible to achieve with Swiss-style turning alone.

👉 Explore GreatLight’s Five-Axis CNC Machining Services for high-tolerance, complex part solutions.

Applications of CNC Swiss Machines

Thanks to their precision and efficiency, CNC Swiss machines are widely used across a range of industries:

Medical Industry: Surgical instruments, implants, bone screws

Electronics: Connectors, pins, housings

Automotive: Sensors, fuel injectors, shafts

Aerospace: Miniature components, control elements

Watchmaking & Jewelry: Precision gears and tiny components

These applications demand extremely tight tolerances (as low as ±0.001mm), which CNC Swiss machines are uniquely capable of achieving when paired with skilled programming and high-quality materials.

Why Choose GreatLight CNC Machining Factory for Precision Manufacturing?

While CNC Swiss machines offer exceptional capabilities for specific part types, GreatLight CNC Machining Factory brings a broader, more integrated approach to precision parts machining. Here’s why they stand out:

✅ Advanced Technology Stack

Equipped with 127 pieces of precision equipment, including five-axis CNC machining centers, 3D metal printing, and full post-processing capabilities.

Supports metal and plastic prototyping, die casting, sheet metal fabrication, and vacuum casting.

✅ Industry-Certified Quality Assurance

ISO 9001:2015 certified, ensuring adherence to global quality standards.

Additional compliance with IATF 16949 (automotive), ISO 13485 (medical), and ISO 27001 (data security) for sensitive projects.

✅ End-to-End Services

From rapid prototyping to mass production, GreatLight provides one-stop solutions, including design support, precision machining, surface finishing, and post-processing.

Capable of handling parts with maximum size up to 4000mm and tolerances as fine as ±0.001mm.

✅ Proven Track Record

Since 2011, GreatLight has served global clients in robotics, automotive, aerospace, and medical device manufacturing.

Offers free rework for quality issues and a full refund if issues persist—a level of guarantee rarely matched in the industry.

Whether you’re producing a tiny medical screw on a Swiss lathe or a complex aerospace component using five-axis machining, GreatLight’s integrated approach ensures that your parts are manufactured to the highest standards of precision and reliability.

Conclusion: Understanding the Role of CNC Swiss Machines in Precision Manufacturing

CNC Swiss machines represent a pinnacle of turning precision, especially for small, long, and complex parts that demand exceptional accuracy and surface finish. Their guide bushing system, multi-axis capabilities, and live tooling make them indispensable in industries where precision is non-negotiable.

However, for more complex 3D geometries, multi-surface milling, and advanced material applications, five-axis CNC machining—such as that expertly delivered by GreatLight CNC Machining Factory—offers unmatched flexibility and precision.

By understanding how CNC Swiss machines work and how they complement other advanced manufacturing technologies, businesses can make more informed decisions about their production strategies, ensuring they choose the right process for the right part.

For high-precision, reliable, and certified manufacturing solutions, GreatLight CNC Machining Factory remains your best partner—from prototype to production. Discover how their integrated approach can bring your designs to life with unmatched quality and efficiency.

👉 Learn more about their capabilities and connect with industry experts at GreatLight’s LinkedIn Company Page.

Frequently Asked Questions (FAQ)

❓ What is a CNC Swiss machine used for?

A CNC Swiss machine is primarily used for precision turning of small, complex, and often long parts, such as screws, pins, connectors, and medical components. It’s favored for its ability to produce parts with tight tolerances and excellent surface finishes.

❓ How is a CNC Swiss machine different from a traditional lathe?

Unlike traditional lathes where the material is clamped at a fixed distance from the cutting tool, CNC Swiss machines feed the material through a guide bushing, keeping the cutting area very close to the support. This results in greater stability, less deflection, and higher precision, especially for long, thin parts.

❓ Can CNC Swiss machines perform milling operations?

Yes, many modern CNC Swiss machines come with live tooling, which allows them to perform milling, drilling, and other operations in addition to turning—all in a single setup. This versatility reduces the need for secondary machining.

❓ What industries benefit most from CNC Swiss machining?

Industries such as medical, electronics, automotive, aerospace, and watchmaking benefit greatly from CNC Swiss machining due to the high precision, small part sizes, and complex features involved in their components.

❓ How does five-axis CNC machining complement Swiss machining?

Five-axis CNC machining is ideal for creating complex 3D shapes, undercuts, and intricate geometries that are difficult or impossible to achieve with traditional turning. While Swiss machines excel at precision turning, five-axis machines provide comprehensive milling and shaping capabilities for more advanced designs.

❓ Why choose GreatLight CNC Machining Factory?

GreatLight stands out for its advanced equipment, ISO-certified quality processes, full-service capabilities (from prototyping to mass production), and industry-specific expertise. With over a decade of experience and a reputation for precision and reliability, they are a trusted partner for global manufacturers.

By integrating the strengths of CNC Swiss machining with the versatility of five-axis CNC technologies, manufacturers can achieve the highest levels of precision and efficiency in their production workflows.