This article introduces the use of the leakage mold castor technology to produce wheel hubs with a diameter of 1250 mm and a single weight of 1500 kg. are designed. .

01

Basic information from Wheel Hub

The author’s company is a belt conveyor produced by Yidong Company in interior Mongolia. ZG270-500, which requires good welding. .

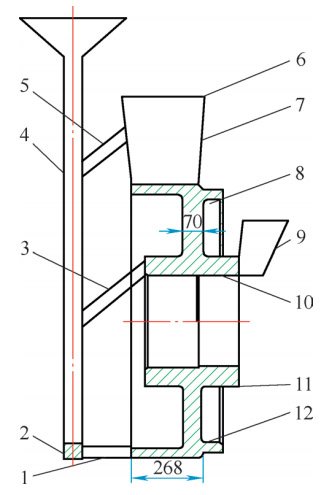

Figure 1 wheel hub

02

Disappear mold breaking process

(1) White type production

There are mainly two types of missing mold models: manual molding and molding of training mechanisms. The handmade molding is suitable for small lots or monobloc casts with a relatively simple cavity, and the formation of formation mechanism is suitable for parts with large lots and complex structures. The wheel hub has a large size and a tight construction period, so the manual model can better respect the real production situation. The workshop process group divides it into three parts according to its structure: wheel circle, secondary plate and central part, which are respectively linked after being released, leaving the treatment volume by 10 mm and increasing the volume of treatment of 3 mm in the upper and lower directions to avoid longitudinal withdrawal during the payment process, the treatment volume is insufficient and the link process must be carried out on the platform to ensure that the circle of the medium and wheels is concentric. The raw material of the wheel hub has a density of 22 g / cm3 to effectively reduce the deformation during the coating and the packaging. .

(2) track design and rising column

The right runner uses 65 mm × 65 mm, the lower horizontal runner is 65 mm × 60 mm and 100 mm is left to both ends to make a group collection set and connect double interior runners of 60 mm × 50 mm for Ensure the liquid steel climb. The interior runner of the second layer is only one 65 mm × 50 mm, connected to the medium edge greater than 45 ° to the main runner. Continue to fill in to ensure that the filling is stable and powerful, and secondly, it can be used to fill it. The three -layer runner is a single 65 mm × 50 mm, connected to the middle of the rising column 45º to the main runner, ensuring that the temperature of the liquid steel at the end of the flow in the rising column is high, this which is conducive to replenishment and withdrawal and can effectively reduce the volume of the rising column by 1/3. -The goalkeeper.

Figure 2 Wheel Hub Process

1. Double Inner Runner 2. Cross Runner 3. Interior runner on the second floor

4. RUNNER Right 5. Inner runner with three layers 6. Actual position 5

7. Fill the rising column 8. The real position of the earthquake 4 9. The rising column of the Fallr

10. Serious position

(3) Painting preparation and brushing process

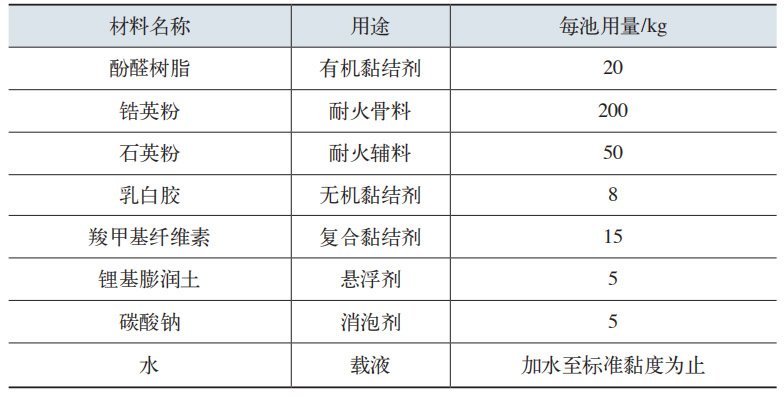

① Painting preparation technology. The composition of the hub covering is indicated in the attached table. When preparing the coating, first use a 1:10 report to match the bentonite and hot water and dispersal it at high speed for 30 to 40 minutes in the mixer to make a uniform bentonite suspension ; , Soak the carboxymethyl cellulose in the water to dissolve it after being stuck, use it, then mix the lithium bentonite suspension, a prepared liquid binder, etc. With refractory aggregates to paint. The viscosity of the paint, stir for 2 hours, release it and transfer it to the pool for use.

② Brushing and drying process. After having assembled the runner, the rising column and the wheel hub, the integrated coating is ensured to guarantee the integrity of the coating, which is conducive to the protection of the purity of the steel during the payment process, and vertically shape during the paint process to ensure that it does not deform. The third brush is only applied to carrots, runners and the cavity, and heat sections.

Room composition content table

(4) Packaging

① Sand box design. The size of the sandbox is 1500 mm long, 1500 mm wide and 2300 mm high. The model’s gasification output.

②S and design of food quantity. The bottom is 200 mm, the east side of 150 mm and the top is 400 mm.

③CeSign of other links. Pressure angle 40º, production of three -dimensional shock 5 times, each time 2 min, acceleration of vibration 10 m / s, frequency of vibration 30 Hz, the type of sand is the sand of pearl, the positions of implementation of shock are respectively in Figure 2, the realization of shock 1, the realization of shocks 2, realization of shocks 3. Flow 4. Flow 5. Place bricks of magnesium carbon 40 mm thick at the bottom of the junction of the right runner and Horizontal runner to prevent liquid steel from eroding for a long time to destroy the layer of paint at the bottom of the runner and bring it in the pearl sand.

(5) Fighting and steel payment

Depending on the existing workshop equipment, an average 3T / h frequency induction melting oven is used and the oven lining is a dry silicon type oven; Used in the oven. Furnace sampling: WC? 0.3%, WMN = 0.6%~ 0.8%, WSI = 0.17%~ 0.37%, WS≤0.035%, W P≤0.035%. The steel output temperature is between 1680 ℃ and 1700 ℃ and 4.5 kg of deoxyaluminium are added when the steel output is discharged. The basin is in 3T rod bag. The thermal isolated rice ball should be added to prevent steel. 5 minutes before pouring, make sure that the negative pressure pump operates normally and check if the negative pressure of the sandbox can meet the payment requirements. , then wait for the payment. The payment temperature is 1660 ℃ ~ 1670 ℃, and the payment method is the lower payment.

(6) Boxing and falling sand

The wheel hub paid should be kept in the sand housing for more than 12 hours, and the sand can be returned and removed after cooling within 300 ℃. Too large, and the cooling speed will be fast, which will be easy to be generated.

(7) Cut

Cut the rising column and the casting system, the cutting surface is flat, the rising cutting column has a 3 mm margin, and the upper rising column is cut in two or more to avoid an excessive heat input into a Only cut and cracks, then pulled by exploding the hub wheel.

(8) Heat treatment

Heat at 910 ° C, constant temperature for 2.5 hours and cool with the oven for less than 300 ° C. The internal structure of thermal treatment is necessary to be ferrite + perlite, and dendritis and weissites are not authorized to appear. ≥35%.

03

Conclusion

The batch of 8 -room conveyor concentrators was completed in 15 working days. The casting by the author’s company and the improvement of the production efficiency of the wheel hubs flows the cost of the production of Hub Wheel and win a place for the author’s company in fierce competition on the market.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.