Among 3D printing shoe startups, Hilos has been very well received by the market. The Portland, Oregon company uses HP Multiple Jet Fusion (MJF) technology for 3D printing to create more durable shoes. In March 2023, Mohou.com learned that Hilos raised US$3 million in an investment round.

△Elias Stahl, CEO of Hilos

Investment participants also include former Nike executives and former COO Eric Sprunk, former Nike vice president of global footwear purchasing and manufacturing Greg Bui, and Better Ventures, Builders VC and XRC Labs. Bui personally analyzes and discusses specific projects with Hilos employees. It can be said that the participation of Sprunk, Bui and others represents a high degree of recognition of the Hilos Project process.

3D printed shoes are more environmentally friendly

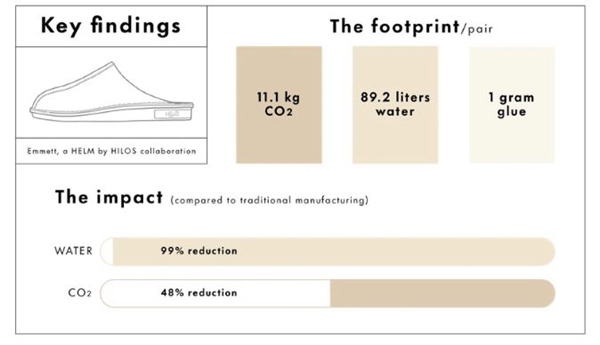

According to a study conducted by Hilos and Yale University, the introduction of 3D printing manufacturing not only makes it possible to produce shoes on demand, resolve inventory requirements and product waste to some extent, but also significantly reduce resource usage.

●Hilos leverages MJF technology to 3D print shoe soles with thermoplastic polyurethane (TPU) made from 80% recycled materials. Hilos said if you no longer want these shoes, they can be 100 percent recycled. The uppers of these shoes are made of leather or knitted fabric. The advantages over traditional shoe manufacturing are numerous.

●Compared to traditional non-slip shoes, the new shoes produced by Hilos in cooperation with the Helm brand reduce water waste by 99% and carbon dioxide emissions by 48%.

●Shoe making itself is a wasteful and time-consuming activity. This involves making a model of the foot, called a shoe last, and then using it to reconstruct a pair of shoes. The manufacturing of most shoes involves 65 parts and 360 manufacturing steps, each of which generates additional waste. Hilos shoes reduce 65 manufacturing parts over 360 manufacturing steps to 5 parts in 12 steps.

●Additionally, Hilos shoes are manufactured locally in the United States, so the benefits of local manufacturing are very obvious.

Elias Stahl, CEO and co-founder of Hilos, said: “Using additive manufacturing technology, we have developed a new model of shoe manufacturing. When a customer purchases a pair of shoes, the factory will manufacture and restock the shoe within 72 hours. hours. The current business model and speed can be said to be incredible. There is no need to make a lot of shoes in advance and store them.

This 3D printed sole features a mesh structure that can cushion the movement process and fully exploits the advantages of generative design and additive manufacturing technology. The end result is a soft, flexible cushion under the foot that makes every step comfortable for the user. The internal geometry reduces impact while walking, reducing wear on the shoe itself. Digital manufacturing thrives on customization, and 3D additive manufacturing allows for more sizes and styles without having to worry about overproduction or understocking. On-demand production opens the way to new business models for the footwear market.

A vote of confidence from Nike

With this funding round, Hilos has now raised a total of $5 million, and the startup continues to grow its business, with former Nike executives also participating in the investment! Currently, one HP machine can be used to produce 500 pairs of shoe soles per month. As the scale expands, dozens of printers can be used to produce more shoes in the future. Hilos has started working with a number of brands, but has not yet disclosed the names of these brands.

Sprunk has been with Nike for 27 years, including seven years as chief operating officer, where he was responsible for driving “the digital transformation of the company.” Regarding Hilos, Sprunk commented that Hilos and its CEO “possess the game-changing passion, creativity and intelligence needed to lead a revolution in shoe manufacturing.”

Greg Bui, former global vice president of global footwear purchasing and manufacturing at Nike, also commented on the project: “it’s actually difficult to launch a disruptive initiative in an industry like footwear. Hilos pioneered the advancement of shoe manufacturing. The market has changed the business model. Let’s wait and see how this develops in the future! »

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.