High-performance processing technology is a key technology for processing critical aerospace parts, leading the aviation industry toward higher production efficiency and processing quality. This technology provides technical support for the high-quality development of critical aerospace parts by improving production efficiency and processing process precision. The advantages and application areas of high-performance machining technology are introduced, and the research progress of high-performance machining technology researchers in the aerospace field is summarized, including high-speed machining technology ( HSM), multi-axis linkage machining technology, micro-machining technology and typical processing of aerospace materials. At the same time, the challenges and development trends that the technology may face in the future are also explored.

1 Preface

The aerospace industry is at the forefront of high-performance machining technology, which places stringent requirements on the performance and precision of mechanical parts, especially those used in harsh conditions such as high temperatures and high pressures.[1]. The manufacturing of these parts relies on precise and reliable high-performance machining technologies, such as high-speed machining, multi-axis machining, micro-machining and typical aerospace material processing. . These technologies not only improve production efficiency and reduce costs, but also ensure part quality and performance.[2]。

In aerospace, key parts such as impellers, blades, casings and thin-walled parts are typically made of high-performance alloys, with complex designs and extremely high precision requirements.[3]. Additionally, these parts are prone to deformation during processing, especially thin-walled parts, which is why high-performance processing technology is very important when manufacturing these critical parts. These technologies not only process difficult-to-machine materials, but also ensure product quality and performance in extreme working environments and complex design requirements, while achieving processing accuracy in the micron to nanometer range.[4]particularly in the production of key parts such as impellers, blades and housings, has demonstrated significant advantages.

In summary, the application of high-performance processing technology in the aerospace field not only improves manufacturing efficiency and product quality, but also stimulates the development of new materials and innovative designs. This is essential to meet the strict standards and complex manufacturing requirements of the aerospace industry.

2 High performance technical processing connotation

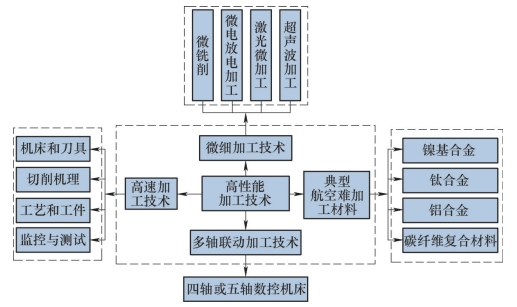

High-performance machining technology is an engineering technology that integrates key elements such as high-speed machining (HSM) technology, multi-axis linkage machining technology, micro-machining technology and technology of difficult-to-machine materials, aiming to improve the efficiency of material processing. , precision and performance. The framework is shown in Figure 1. In the aerospace domain, these technologies are used to manufacture high-demand parts to meet complexity and reliability requirements, thereby leading to the continued advancement of manufacturing technology in this area.

Figure 1 High-performance processing technology framework

2.1 High-speed processing technology

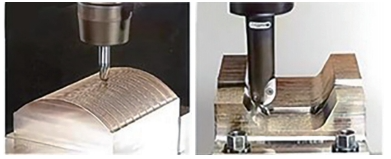

High-speed machining technology in the aerospace sector plays a key role in the production of complex and precision parts. It shortens the production cycle and improves the surface quality of parts by increasing the material removal rate and optimizing the machining path. In high-speed milling, solid, indexable ball end mills are used to process complex structures on convex and concave surfaces and five-axis CNC milling machines. Milling operations are illustrated in Figure 2, reflecting the diversity and complexity of the technology.[4]。

a) Milling a convex surface b) Milling a concave surface

c) Milling of complex structures

Figure 2 Milling processing under different working conditions[4]

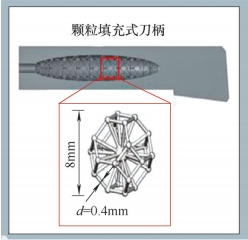

For specific TC4 titanium alloy materials, Wang Sheng et al.[5]By optimizing the milling parameters of PCD tools, significant improvements in processing efficiency and surface quality have been achieved. LUIS et al.[6]The study found that in complex surface milling, maximum radial depth, feed rate and down cutting strategy are critical to improving surface quality and productivity. VOGEL etc.[7]An advanced tool holder with a particle-filled internal structure has been developed and tested for turning at Monfort Company. As shown in Figure 3, it improved machining efficiency and tool life by reducing vibration when machining titanium alloys.

a) Test setup

b) Structure of the tool handle

Figure 3 Filled Toolholder Test Setup and Toolholder Structure[7]

Additionally, the application of advanced CAM systems, such as Mastercam, UnigraphicsNX, and CATIA, provides various tool path strategies for machining.[8]. HASCOET AND RAUCH[9]The use of the OpenNC controller and NURBS toolpath interpolation further improves the quality and efficiency of high-speed machining, bringing significant advancements to the aerospace industry.

2.2 Multi-axis linkage processing technology

In the aerospace industry, multi-axis linkage machining technology, especially the application of four- and five-axis CNC machine tools, has significantly improved the production efficiency and quality of key parts and has brought significant innovation.

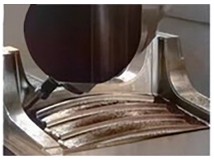

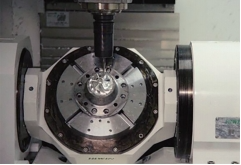

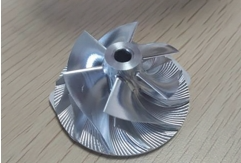

In terms of researching specific applications, FAN et al.[10]A specialized five-axis machining method for centrifugal wheels has been developed. It divides the wheel into different zones and optimizes the tool path for precise and efficient milling. MHAMDI et al.[11]A dynamic Ti-6Al-4V multi-axis milling model of aircraft engine blades was developed to achieve better precision and surface quality in blade manufacturing and solve complex shape and material problems. Chen Kaihang[12]A semi-real-time speed planning method for five-axis CNC machining of turbine was developed, which effectively improved the quality and efficiency of machining and met the actual needs of the project . Taking the semi-open integral wheel as an example, the processing site of the multi-axis linkage and the samples are shown in Figure 4.

a) Turbine finishing process

b) Semi-open integral wheel

Figure 4 Multi-axis linkage processing site and example parts

Additionally, literary figures such as[13]A new method is developed to generate tool axis vectors for mesh surface machining to improve the efficiency and precision of multi-axis CNC cutting machining. Wang Bo et al.[14]A method for modeling the trajectory of advanced microelements in multi-axis ball milling has been developed. They built a dynamic model integrating the geometric characteristics of the tools to accurately predict milling forces.

Multi-axis linkage machining technology is increasingly widely used in the aerospace field, and its improvement in production efficiency and manufacturing quality cannot be ignored. The development and application of this technology has opened a new avenue for more innovation in the aerospace industry in the future.

2.3 Micromachining technology

In aerospace, micro-machining technologies including micro-milling, micro-EDM, laser micro-machining and ultrasonic machining play a vital role. These technologies play a key role in the manufacturing of microscopic components with complex shapes and high precision requirements.

Micromilling technology has advantages in manufacturing high-precision micro-components and complex geometries. Tian Lu et al.[15]made progress in minimizing cutting thickness and optimizing cutting force, while LI et al.[16]A new Ti(C,N)/WC/ZrO2 composite micro-nano ceramic tool material for micro milling cutters has been developed, which effectively improves the bending strength, toughness and hardness of cutting tools. Furthermore, Zhang Xinxin et al.[17]Optimizing cutting parameters for high-speed micro-milling of tough materials such as titanium alloys and stainless steel improves the surface quality and processing efficiency of these difficult-to-machine materials.

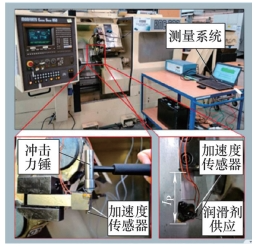

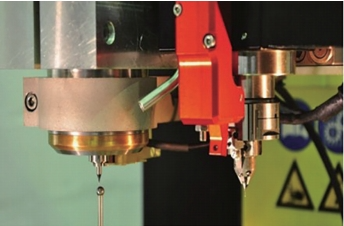

In the field of micro-electroerosion machining, Tagawa[18]The effect of micro-EDM machining on improving the processing efficiency and surface quality of Ti-6Al-4V titanium alloy was confirmed. LIN et al.[19]The micro-milling EDM of Inconel 718 has been optimized using the Taguchi method to achieve a balance between electrode wear, material removal rate and working space, thereby improving efficiency cutting. HUU et al.[20]The use of carbon-coated electrodes improved the machining efficiency of titanium alloys, demonstrating the potential of contactless machining in hard materials. While GARZON et al.[21]The research focuses on force measurement technology in micro-EDM, providing more precise monitoring of the machining process. The combined processing platform built and optimized for this device on the Sarix sx200 machine tool is shown in Figure 5.

Figure 5 Combined processing machine tool: micro milling + micro EDM[21]

The development of laser micromachining technology has greatly improved the local processing performance of various materials, such as CHAVOSHI.[22]Studies have shown that local processing of various materials with high-energy laser beams improves processing performance. Xiao Qiang et al.[23]Micro and nanostructures have been successfully fabricated using femtosecond laser processing. SUN, etc.[24]Using µCT to detect void defects in laser-additively manufactured Ti-6Al-4V provides important information for aerospace quality assurance.

At the same time, ultrasound treatment technology has also made significant progress. Peng Zhenlong et al.[25]The developed high-speed ultrasonic wave cutting technology improves the cutting speed and efficiency of difficult-to-machine materials, and ZHAO et al.[26]Using a RUVAG device developed by RUVAG based on workpiece vibration, a single CBN grain grinding test was carried out to reveal the material removal mechanism and grain wear performance of CBN by radial ultrasonic vibration. LIU et al.[27]The proposed ultrasonic-assisted pecking drilling (UPD) method effectively improves the drilling efficiency and quality of CFRP/Ti laminated materials.

The comprehensive application of micro-machining cutting technologies not only demonstrates their unique advantages, but also shows great potential in manufacturing high-precision micro-components and complex designs. As micro-cutting technology continues to develop, it will continue to promote advancements in aerospace and other precision manufacturing industries.

2.4 Typical aviation materials that are difficult to process

In the aerospace industry, research into precision machining technologies for typically difficult-to-machine materials such as titanium alloys, aluminum alloys and carbon fiber composites is crucial. These materials play an important role in the manufacturing of critical aeronautical parts due to their excellent mechanical strength and corrosion resistance, but they also pose processing challenges.

In the field of titanium alloy processing, Tian Rongxin et al.[28]A process parameter optimization method is proposed for high-speed milling of TC11 titanium alloy. Liu Peng et al.[29]A mathematical model to optimize the cutting force of the PCD tool during high-speed milling of TA15 titanium alloy was developed and its effectiveness was verified. HOURMAND et al.[30]Studies have shown that tools coated with tungsten carbide (WC or WC/Co) perform better in terms of wear, smoothness, life and friction than uncoated tools. EZUGWU et al.[31]Through research, it was found that when using PCD tools for high-speed and precision TC4 turning, high-pressure cutting fluid can significantly improve surface smoothness and service life of the tool and reduce physical damage. Additionally, Yao Jun et al.[32]By applying electrolytic vibration cutting technology, the processing efficiency of TB6 titanium alloy is effectively improved and the cost is reduced.

In terms of aluminum alloy processing, DONG et al.[33]The focus is on diamond tool wear during precision machining, highlighting the effects of tool clearance and feed rate. WANG et al.[34]Research on machining 7050-T7451 aluminum alloy shows that larger cutting angles and thicker chips can significantly reduce energy consumption, resulting in more efficient and environmentally friendly manufacturing. of the environment. Furthermore, JAROSZ et al.[35]By optimizing the CNC surfacing parameters, the processing time of AL-6061-T6 aluminum alloy is significantly reduced (about 37%) and the processing efficiency is improved.

In addition, for processing aerospace carbon fiber materials, WU et al.[36]Polycrystalline diamond cutting tools for carbon fiber reinforced plastics (CFRP) have been developed to improve cutting efficiency and quality. ZHANG et al.[37]The developed stochastic model can accurately predict the cutting force during milling of fiber-reinforced composite materials, which is of great significance for improving the precision and efficiency of composite material processing. Wu et al.[38]The finite element model and Deform 3D software were used for simulation analysis to solve the drilling problem and improve the processing quality.

In summary, in the aerospace field, processing technology for typical difficult-to-machine materials is the key to achieving high-performance manufacturing of critical aerospace parts. The development of these cutting technologies not only improves processing efficiency and precision, but also opens up new possibilities for cutting, processing and forming other new, difficult-to-machine materials.

3 Application cases of high-performance technological treatments

3.1 Multi-axis machining of wheel blades

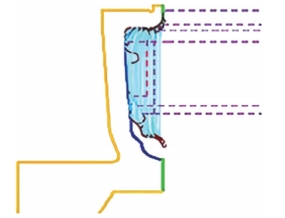

Taking the five-axis machining of an aviation integral wheel as an example, the milling method of the complex surface geometry of the integrated wheel blades is considered in advance, and the point milling method and the side milling method are used. Next, consider cutting tool selection when finishing adjacent blades to avoid overcuts and undercuts, then select a taper shank milling cutter and combine it with CAD’s distance analysis function to the analysis. Then, the tool position path is designed via the “blisk” mode of the PowerMill software. Finally, in order to ensure the safety and reliability of five-axis machining, VERICUT simulation software is used to simulate the overall machining of the wheel to ensure that the machining is safe and reliable and meets the requirements of size and precision.[39]. The main questions and methods are summarized below.

1) Ensuring the overall efficiency and precision of turbine processing is the key to processing technology. The point milling method and side milling method are used in the milling process, and the curved surface of the blade is processed step by step along the streamlined direction of the blade by point contact and linear contact. Using this processing method ensures processing efficiency and surface quality.

2) To prevent the tool from cutting too much or too little when finishing adjacent blades, combine the taper shank analysis and CAD software to determine the minimum blade spacing, reserve the allowance for machining and oscillation angle of the cutter axis, which not only improves the processing efficiency, but the rigidity of the tool is also improved.

3) Reasonable tool path design is the most important step in multi-axis machining. Using the “blisk” module of PowerMill software, through parameterized parameters and strategic design, we can construct auxiliary surfaces and perform collision and overcut inspections, etc., so as to formulate position trajectories. ‘effective and reasonable tool and achieve good results in subsequent real situations. treatment.

4) In order to ensure the safety and reliability of five-axis machining, VERICUT simulation software is used to simulate the actual machining environment and process tooling, and combined with the tool path In the CNC program, the feasibility of processing the overall wheel is checked.

3.2 Processing of thin-walled, high-hardness annular parts of the motor crankcase

In view of the problems of deformation, vibration and surface quality that may occur during the processing of the thin-walled special-shaped structure mounting ring of the aircraft engine casing, a number of measures have been taken to prevent deformation. Firstly, the rough milling process is added to release the machining constraint in advance. Secondly, elastic diaphragm structure expansion tooling and cycloidal turning processing method are used to effectively avoid workpiece deformation. Finally, turning instead of grinding is used to ensure the surface quality and coating size, thereby solving key problems in machining.[40]. The main questions and methods are summarized below.

1) It is essential to reduce stress and deformation during further processing and improve the efficiency and quality of the entire manufacturing process. Excess material on the end face is removed during the rough milling process to release processing stress and reduce warpage, while still leaving the necessary margin for finishing. This process not only improves processing efficiency, but also reduces internal stress through stress-relieving annealing, ensuring the precision and quality of parts.

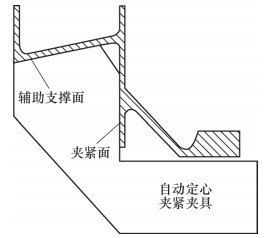

2) In order to solve the problem of serious deformation of parts during processing. By designing special tools and adopting efficient turning technology (see Figure 6), the deformation during processing is effectively controlled, thereby ensuring the processing precision and quality of parts. This method is suitable for processing similar high-hardness thin-walled special-shaped parts, which can improve processing efficiency and reduce tool wear while ensuring surface quality and coating size.

a) Pliers with elastic clamping structure

b) Trochoidal turning diagram

Figure 6 Processing of mounting and cycloidal turning[40]

3) In order to solve the problem that the large vibration caused by the grinding process causes vibration marks on the surface of the coating and it is difficult to meet the surface roughness requirements, the turning process is used instead, using special turning tools and reasonable processing. processing parameters. Compared with grinding wheels, the contact area of the rotating coating is smaller, which effectively reduces vibration, improves the surface quality and dimensional accuracy of the coating, and meets manufacturing requirements.

4Conclusion

This article provides a comprehensive review of high-performance machining technologies in the aerospace domain, highlighting the important role of these technologies in aerospace manufacturing. He highlighted the importance of high-performance machining technology to improve production efficiency and quality of critical parts and ensure performance under extreme conditions, and then presented specific application examples to demonstrate the role of these technologies in improving machining precision and significantly reducing deformation and vibration. benefits. However, in the rapidly developing aerospace field, high-performance processing technology still faces many challenges. The future aerospace manufacturing industry will focus on integrating innovative technologies such as digital twins and smart manufacturing, while focusing on environmental sustainability and promoting the development of greener materials and processes. More efficient, intelligent and environmentally friendly technologies will drive the arrival of a new era. .

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.