Elevating Precision Manufacturing: Great Light Metal Tech Achieves Dual ISO Certifications for Security and Medical Excellence

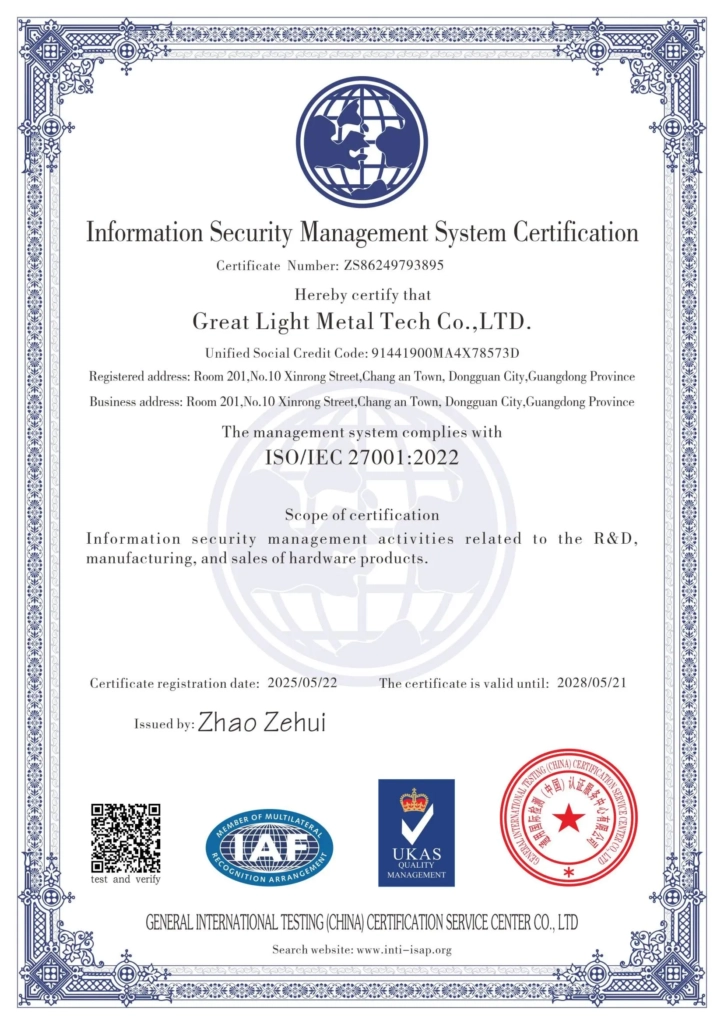

In an industry where precision meets compliance, GreatLight Metal Technology Co., Ltd (东莞市钜亮五金科技有限公司) has solidified its leadership by securing two critical international certifications: ISO/IEC 27001:2022 for information security and GB/T42061-2022/ISO13485:2016 for medical device quality management. These achievements underscore their commitment to operational excellence across hardware R&D, manufacturing, and sales—particularly for mission-critical sectors like healthcare.

Why Dual Certifications Matter in CNC Machining

For manufacturers of precision metal parts, certifications aren’t just badges—they’re operational blueprints. Great Light’s credentials validate their capability to:

1. Safeguard Intellectual Property & Data (ISO 27001:2022)

- Scope: Protects information security across R&D, production, and sales of hardware products.

- Client Impact: Ensures confidential design files, material specs, and project data remain secure during online customization processes.

- Industry Gap Solved: Mitigates IP theft risks common in outsourced metal parts manufacturing.

2. Guarantee Medical-Grade Reliability (ISO 13485:2016)

- Scope: Governs R&D, production, and sales of medical-grade hardware for devices.

- Client Impact: Delivers traceability, biocompatibility assurance, and batch consistency—critical for FDA/CE-compliant devices.

- Technical Edge: Enables machining of surgical instruments, implant components, and diagnostic equipment with ≤5μm tolerances.

Beyond Certifications: Great Light’s 5-Axis CNC Capabilities

As a professional 5 Axis CNC machining factory, Great Light transforms certifications into tangible advantages:

Advanced Manufacturing Infrastructure

- Material Versatility: Processes stainless steel, titanium, aluminum, and exotic alloys.

- Complex Geometry Mastery: 5-axis simultaneous machining for contours, undercuts, and thin-walled structures.

- One-Stop Finishing: Anodizing, passivation, laser etching, and medical-grade polishing.

Speed-to-Market Engine

- Rapid Prototyping: 15-day lead times for complex custom metal parts.

- Scalable Production: Runs from 1-piece batches to 10,000+ units with consistent quality.

- Digital Integration: Real-time project tracking via their online portal.

The Trust Equation: How Certifications Boost Client Outcomes

For engineers sourcing CNC machining services, Great Light’s credentials translate into:

Risk Reduction

- Zero data breaches during client collaborations (ISO 27001 compliance).

- Elimination of non-conformance costs in medical audits (ISO 13485 documentation).

Supply Chain Resilience

- Full material traceability from raw stock to finished parts.

- Validated processes for aerospace, automotive, and medical sectors.

“In precision manufacturing, certifications are the silent guardians of quality. Great Light’s dual ISO achievements signal their mastery of both digital security and physical excellence—a rare synergy in CNC machining.” — Industry QA Director

Partner with a Certified Leader

Great Light merges technological prowess with uncompromising standards:

✅ ISO 27001-certified data security for IP-sensitive projects

✅ ISO 13485-compliant medical hardware production

✅ 5-axis CNC precision (±0.005mm)

✅ One-stop finishing services

Customize your medical, aerospace, or industrial metal parts with a partner whose certifications are operational realities—not just paperwork.