“The large number of exhibitors at Formnext reflects the importance of additive manufacturing for the entire industrial sector,” said Sascha F. Wenzler, vice president of Messe Frankfurt GmbH, organizer of the exhibition. responds to current challenges and unlocks new economic potential. “At the same time, Formnext also demonstrates how dynamic the global additive manufacturing industry is, with countless innovations and applications paving the way for the future of industrial development every year. »

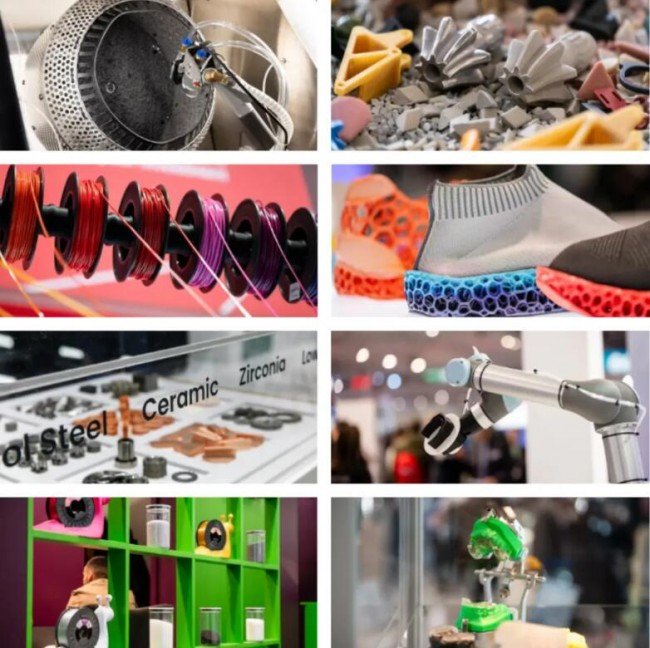

So far, 61% of registered exhibitors come from countries outside Germany, with the main countries being the USA, China, the UK, France, the Netherlands, Italy and Spain. The additive manufacturing (AM) industry has a tradition of letting the most important innovations throughout the year be published and exhibited at the Formnext exhibition, which allows visitors to experience the latest additive manufacturing technologies up close and to interact directly with experts and exhibitors. This year’s exhibitors will not only showcase their new applications, but also plan to highlight how manufacturers can integrate additive manufacturing technology into their production lines more cost-effectively and efficiently.

![]() Formnext Price

Formnext Price

The perfect scene to progress

Activities supporting Formnext 2024 will include some existing activities and exciting new highlights. The Formnext trade show and conference has refined its awards ceremony concept over the years and is launching the Formnext Awards this year as a new way to put more emphasis on exceptional talents and their innovative ideas. The awards will be presented in six different categories, including innovative start-ups, sustainable business ideas and pioneering technologies. This year, the entire additive manufacturing community can participate in the selection process and vote for their favorite winners, whether they are in Frankfurt or not. In addition to visiting the Formnext trade fair to experience the products and technologies in person, everyone can also find out about the situation in advance on the Formnext website (www.formnext.com) from mid-October . Voting in all categories will close at noon on November 21, 2024 and public votes will be taken into account as additional jury votes.

At the same time, Formnext will continue its extensive presentation content (open to all participants) to promote high-level discussions on the most recent topics. This means that in 2024, current and future applications, technologies and general trends in the additive manufacturing and production industry will once again be at the top of the agenda. Key topics in applications, industry and technology will include artificial intelligence in additive manufacturing, medical and dental technology, robotics, automation and much more. The special “Provider Marketplace” exhibit space will also return after its debut last year, showing companies how to benefit from revolutionary additive manufacturing technology without having their own in-house production operations. Corresponding exhibitions will showcase innovations in areas such as medical technology, dentistry and packaging.

During the “Startup Zone” and “Pitchnext” events, young innovative companies in the manufacturing industry will have the opportunity to present themselves to potential investors and partners. Those interested in working in the additive manufacturing industry will also have the opportunity to view current job opportunities during Career Day (the third day of the show). As in previous years, companies looking to enter the additive manufacturing industry will find excellent advice and information at the Discover3Dprinting seminars, co-hosted by the organizers and ACAM and held each day of the show. ACAM will also partner with Formnext to host four in-depth workshops on topics including AM industrialization, AM design, surface treatments and materials.

At Formnext 2024, the VDMA Additive Manufacturing Working Group will present, together with its members, practical applications of additive manufacturing in the field of mechanical engineering in the Additive4industry exhibition area. The BE-AM seminar and accompanying exhibition space will showcase advanced developments in 3D printing technology in the construction sector, which is growing in importance. The day before the official start of this year’s Formnext Exhibition and Conference, VDMA and ASTM International will jointly host the Formnext Additive Manufacturing Innovation and Standardization Summit. Finally, in another special exhibition space, the finalists likely to win the Hessian Design Award will be awarded and the final winners will be announced during the awards ceremony.

Formnext is delighted to have Australia as a partner country for 2024! This diverse continent has impressed for many years with its vibrant additive manufacturing community and successful system suppliers around the world, as well as its service providers and other highly specialized companies in the additive manufacturing sector. A deep impression. The basis of it all is an exceptional university and a unique environment that attracts talented people from all over the world.

November 19-22, 2024

See you in Frankfurt, Germany!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.