2022Year10moon25day, located in Bristol, United KingdomGKN Aerospace (GKNA) The company is developing an exclusive laser metal wire deposition system (LMD-w) The technology can be applied to the manufacturing of large aerospace components. The company is a manufacturer focused on airframe and engine products for civil and defense customers, with expertise in metals and composite materials.

The adoption of additive manufacturing is consistent withGKNAIn pursuit of a more sustainable aerospace future, the company recognizes the role of additive manufacturing in optimizing the weight of engines and structural components./value in terms of cost, while recognizing the challenges they currently face in ensuring repeatability of their manufacturing.

GKNA Chief Technologist Tim HopeTimHope“Fundamentally, we need to build trust,” Cost of Defaults said. The role of metal additive manufacturing technology is to reduce technical risks and provide better services to customers.

existGKNAIn the factory there are many slavesEOSAndrenishawPurchases of direct laser sintering of metals (DMLS) the system is running. Furthermore, thanks to AIR TRANSPORT Laser deposition by metal line developed by a research program (LMD-w) This technology is currently used in the company’s engine sector. It is understood thatLMD-wThe maximum print size allowed by the technology has been reached3meters and is expected to be used in aerospace structural products.

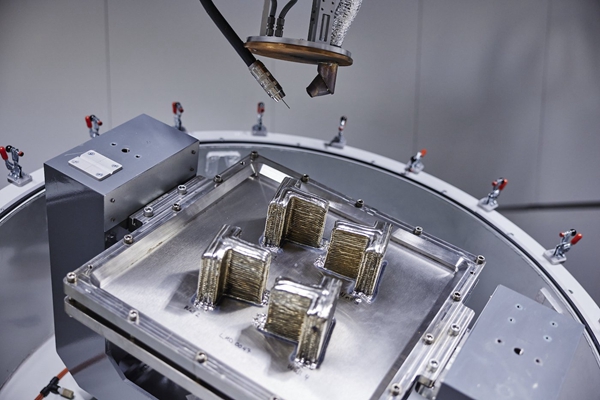

△GKN Aeronautics pass AIR TRANSPORT Exclusive laser metal line deposition developed by a research program (LMD-w) technology.

although GKNA Already usedLMD-wThe equipment prints the flight parts, but they still need to further validate the technology: according to their own standards, those of their customers and the authorities. Certification of new processes such as additive manufacturing remains GKNA One of the biggest challenges faced, and while process monitoring and simulation can help solve this problem, open systems would also be of great help. SO,GKNAcan guarantee its LMD-wProcess quality, but for introductory technologies such as powder bed fusion, also requires establishing good relationships with suppliers.

GKNA Another person in charge ofHuguesPointed out: “If your customers are in the aerospace sector, then you need to understand that all parties in the additive manufacturing supply chain, the end service target of flight parts are the aviation authorities. Customers describe the information they need and our customers. the entire value chain. You have to make judgments based on this information, and it depends on the heat treatment, powder supplier, machine supplier, etc. If there are gaps you can’t see, that’s a challenge.

△ Located in Filton, Bristol GKN Aeronautics Global technology center.

In other workshops,GKNAHe also introduced aStratasys Developed jointly with HP Designjet machine, one Ultimaker S5A Formlabs 2 form Waichi Unit Markforged Mark2. These machines (including Designjet) are often called upon to produce templates, fixtures and design aids, but GKNA This never stops on the desktop platform. exist Designjet After,GKNA Next to be featured 3D The printing system is Arcam A2。

exist GKNA Among the printed pieces on display are models of tanks and other uses. LMD-w Manufactured close to sharply shaped parts as well as usingDMLSCertified support components made with technology. Engine parts constitute the main order produced by its powder bed fusion equipment, while itsLMD-w technology can be used to create theseDMLSLarge component structures that are difficult to process technically. With its powerful3D printing capabilities,GKNA Internal confidence grows. The company actively participates in a series of standards working groups, recognizing NASA、ASTM And SAE and other organizations have made progress in developing such standards in recent years and maintain good relationships with commercial and academic institutions. But by following these standards,GKNA Not only is it important to ensure that the technology manufacturing process is repeatable, but there is also a cost associated with generating the dynamic properties required for aerospace parts.

Hope Estimate: “In aerospace, there are only two challenges with additive manufacturing: the productivity challenge and the certification challenge. Can you make the right part the same way every day is a huge technical challenge. And then, does it cost? -efficient compared to other processes? Once you identify these two key factors, you can get to the real winning criteria for additive manufacturing in terms of what is possible in the future, but for that to happen we need to be able to integrate them. For aircraft, it is about the confidence of regulators and end users in the price/performance ratio.

HuguesAdded: “Additive manufacturing is now on the commercial side of the hype curve. You’re going to see a lot of cool things, but we need to implement it in a real way on real applications to unlock cool things for the future. if we can achieve real results in the short and medium term Business benefits and long-term returns? We can all see topology optimization, functional integration in the field of additive manufacturing, these are all good things, but the confidence of customers and certification bodies in this technology is what it needs now. , this is where our attention is focused.

△Use GKN Aeronautics of LMD-w Technically printed parts.

GKNA Aiming to remain a leader in its field, Hope believes the key to achieving this goal is ensuring the sustainability of the business: “The aerospace sectorOEM Not a lot, so everything we do in additive manufacturing is about building supplier confidence. If you understand our customers’ needs and can meet their deadlines, you will have a sustainable business. Innovation comes from market demand, commercial and technical feasibility, and the three must be combined. But you will only succeed if you can do it repeatedly and with confidence. “

existGKNAAt the back of the factory hall is a group ofDMLSprinted acoustic lining,HuguesExplained that he received the component dimensional data on Thursday morning and that evening GUJAT Zhong modeled the part, assembled it with the process team on Friday, and by Monday morning it was on his desk, where it was finally used for engine testing. This entire process clearly demonstrates how quickly you can go from idea to prototype, all with the help of powerful metal.3DThe ability to print was put into practice.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.