Aluminum alloy materials such as F357 are often used in the production of structural parts via additive manufacturing due to their low shrinkage and narrow solidification temperature range. These materials can provide a viable and inexpensive alternative to titanium, especially on large parts. However, powder bed fusion 3D printing of F357 can pose some challenges, such as the presence of dissolved gases (hydrogen or argon) which can lead to blistering and poor surface quality of the part.

Mohou.com has learned that in a new study, researchers from Quintus Technologies, SLM Solutions and the University of Arizona found that using new uniform rapid quenching (URQ) and isostatic pressing technology Hot Processing (HIP) could make F357 parts observable without any defects. the ultimate strength and yield strength of the parts exceed those of MMPDS castings, and the geometric deformation is smaller.

The full research white paper is available here:

In many industrial manufacturing processes, hot isostatic pressing (HIP) technology is used to reduce the porosity of metal parts. The process enables densification by applying conditions of high pressure (100 to 200 MPa) and temperature of 900 to 1,250 °C to plated, cast or sintered parts filled with dense powder in an oven. High temperature steels and alloys are two typical examples of materials. . Air pressure acts evenly on the furnace components in all directions to provide isotropic properties and 100% densification.

△Standard F357 320mm vertical test rod construction

The F357 HIP process is generally carried out at temperatures above 500°C and at an argon pressure of 75 to 150 MPa. In addition to having the benefit of increasing the density of the aluminum alloy, it also has the effect of reducing porosity and overall increasing fatigue, toughness and ductility. A standard T6 quenching heat treatment including solution heat treatment and artificial aging is applied after the HIP process to obtain the required mechanical properties, but when a separate solution heat treatment at 540°C is carried out at atmospheric pressure, there are risks: Pores which were closed during the open cycle and became larger during T6.

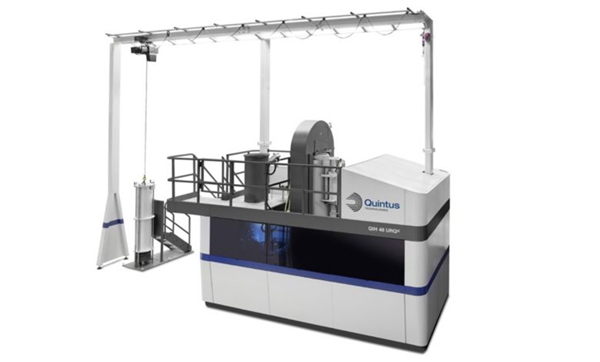

Due to the low diffusivity of hydrogen or argon in the aluminum lattice and the low deformation resistance of the alloy at high temperatures, the high pressure remaining in the pores after HIP may be due to the enlargement of pores caused by T6 tempering. To avoid blistering or TIP, Quintus Technologies, a company specializing in the design of high pressure processing equipment, has developed an alternative to the standard HIP cycle and solution heat treatment, two distinct processes. The new HIP Uniform Rapid Quenching (URQ) furnace enables HPHT (High Pressure Heat Treatment) by combining solution heat treatment and HIP processes. With the URQ system, the combination of heat treatment of HIP and T6 solutions allows the formation of the appropriate precipitation hardening phase during subsequent aging while reducing the risk of pore reopening.

The University of Arizona, SLM Solutions and Quintus Technologies conducted a case study to evaluate the application of HPHT to high-strength aluminum alloy F357 by powder bed fusion laser (PBF-LB) in a HIP-URQ oven. The study evaluated the density, microstructure, mechanical properties and deformation of parts post-treated by this new HIP method. The experimental design materials were printed by SLM Solutions on an SLM 280 PBF-LB 3D printer using F357 aerosol powder.

△A modern Quintus HIP QIH48 heat treatment furnace with URQ capabilities

The results demonstrate that a robust post-processing approach provides excellent tensile properties while avoiding thermally induced porosity and deformation. This study shows that post-processing F357 aluminum using the Quintus URQ process is a promising method for producing high-quality additively manufactured aluminum parts. The benefits offered by the HPHT process include:

Offers tensile strength and ductility comparable to standard HIP+T6 materials;

Reduce the geometric deformation of components, even with complex geometries;

Avoid foaming and reduce cycle time of the entire process.

Additionally, researchers are conducting additional work to evaluate the fatigue characteristics of URQ F357 and further explore optimizing the balance between strength, ductility and manufacturability of these components.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.