2023Year6moon29dayMohou.com has learnedAustrian3DPrinting solutions manufacturerGENERALLaunch of a patented system specially developed for the production of glassesG1/F1Brand new system. Furthermore, he launchedMission Glassesplatform, designed to distribute3DThe manufacturing process of printing eyeglass frames.

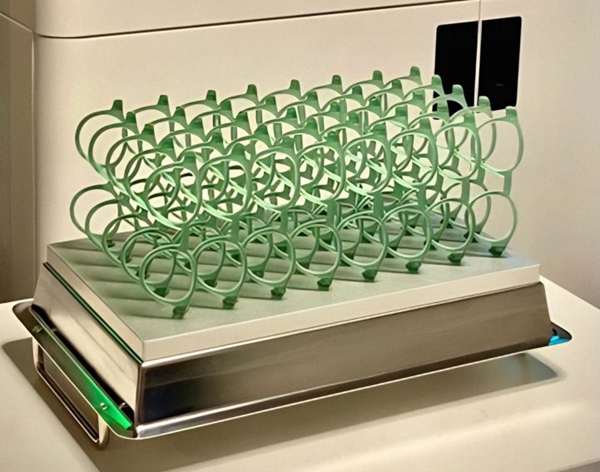

△AdoptSpecters+AndGENERALofDLPtechnology3Dprinted eyeglass frames

Mission GlassesThe platform will allow opticians to download and3DPrint high quality eyeglass frames. It is throughGENERA G1/F1 DLP 3D ModelThis is achieved using a printer and post-processing system in conjunction with a liquid resin specially developed by Henkel called “Digital Acetate”.

GENERALCEOKlaus StadlmannThe Dr explains: “The dental market has become digitalized;GENERALThe goal is to bring digital manufacturing to opticians and the eyewear market. This is why we are happy to beSILMO2023presented to the public G1/F1system andMission Glasses“

It is reported that this year9moon29Solstice10moon2During the appointment,GENERALwhich will be held in ParisSILMO2023The presentation above further demonstrates his solution.

△And tradition3DCompared to printing technology,GENERALInnovation in design and aesthetics of materials

Glasses on demand are the future

The company said that since1240Since the invention of the first pair of glasses in 2000, the eyewear industry has experienced considerable development. Today, eyewear designers and opticians use modern computer-aided design (GUJAT) tools for designing and developing eyeglass frames. Integrating additive manufacturing into the eyewear design, customization and on-demand manufacturing process is certainly a logical step. By combining Henkel’s “Digital Acetate” withGENERALofG1/F1Together, these systems open a new era in eyewear manufacturing: digital series can be produced on demand and are fully automated.

Also,GENERALbrand new3DThe printed products have perfect transparency, translucency and brilliant colors, which is perfect for3DEyewear printing represents a huge step forward for the industry.

Cabrio GlassesofBieke Hoëtcommented: “Currently, distributed generation is fully realized3DPrinting glasses is still impossible. But we understand that brilliant colors and transparency are important to our customers. The perfect surface was also a deciding factor. This is why we want opticians as experts to be able to create our creations directly on site so that they can adjust the glasses at the point of sale to offer the customer the ideal pair. “

△3DPrinted finished frames

Mission Glassesdistributed3DManufacturing of printed glasses

●The principle of this platform is very simple. Well-known eyewear brands offer digital eyewear models.

●Opticians can choose fromGENERALwebsite to get these design files.

●Opticians can use it directly in storeGENERALofG1/F1Technical progress3DPrint the frame and complete it using the parts provided in the file, such as the temples and hinges.

Another major advantage of this platform is that the entire workflow is automated and requires very little manual intervention.G1/F1The system is equipped with aRFIDLabel box system, different materials have their own designated boxes. The system automatically identifies cartons and materials and selects the best production parameters accordingly.

For opticians, the biggest advantage is automationGENERALThe manufacturing process means that all production steps are recorded. This makes the optician a replicator rather than a direct producer. Opticians can also differentiate themselves from other opticians thanks to special lines and build customer loyalty.

By having full control over the production process, opticians can respond quickly and easily to customer demand without relying on external warehouses or unpredictable supply chains, allowing them to produce frames on demand. Additionally, customers can useGENERALpartnersYourGlasses (YE)Online tools provided to design and customize your own glasses.

to useGENERALof3DPrinting technology and materials from Henkel, the optical workshop is able to produce up to100frames. This is perfect for meeting the needs of opticians.

△GENERATE G1/F1System Brings Innovation to Distributed Frame Manufacturing

to useGENERAL DLPtechnical3DPrinted glasses

Until now, traditional3DPrinted glasses have a uniform design style. The main reason is that laser sintered frames are opaque due to their production process and have a matte color. It is therefore almost impossible to produce more filigree frames with the laser sintering process.

Stadlmann“Although the technology is very mature, it is time-consuming and inconvenient in terms of post-processing, and it is not practical to use the powder for in-store distributed production in optical stores or for small batch production of eyeglass labels (test frames),” said Dr.

It’s exactlyGENERALof3DThis is where printing technology comes into play. through itsG1/F1system,GENERALAbility to use digital light processing (DLP) the process produces a range of structures and geometries from liquid resin.

G1to useDLPLayer-by-layer technology implementation3DPrint frames. Once printed, the frame is automatically stored in the shuttle and then insertedF1Perform automatic post-processing. existF1Internally, the frame is cleaned in a specially designed cleaning tank for safe use, then cured in an inert atmosphere to ensure superior results.

△UseGENERALuniqueDLPThe technology isG2/F2Product on the system3DPrint eyeglass frames

Stadlmann“From a technical point of view, the system combines our industrial production systems (G2/F2AndG3), has become a world-renowned brandSpecters+Carry out mass production of eyeglass frames. In this area, our materials partner Henkel uses specially certified liquid resins to produce eyeglass frames that not only meet all eyewear standards, but also usher in a new era in transparency, translucency and color brightness , setting new industry standards. “

The company said:G1/F1The system is also optimized for in-store use and is ideal for use in every optician’s studio or directly on the sales floor. It offers a high degree of operational convenience, clean processes, cartridge systems andGENERALThe same print quality as industrial systems.G1/F1The system also provides opticians with special furniture to optimize storage and workflow.

The company says the success of new technologies may be just a small step towards big success, but for customers one thing is clear and future eyeglass owners can look forward to it.3DPrinted glass is entering a new era in design, materials, color vibrancy and unique transparency and translucency.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.