Introduction: The Engineering Holy Grail of a Bionic Skeleton

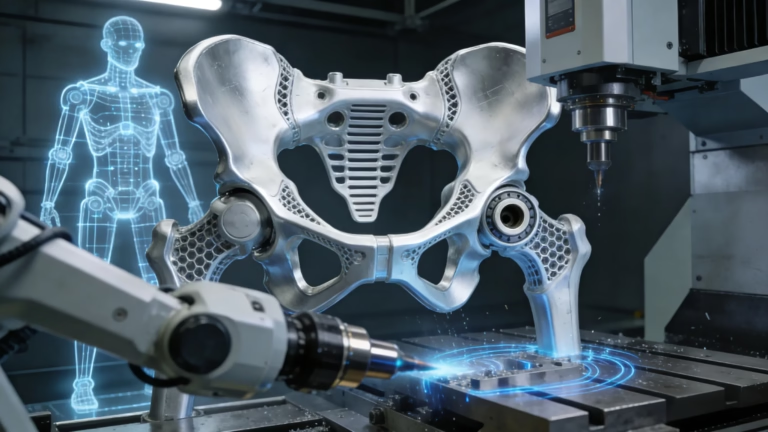

When a humanoid robot walks smoothly, lifts heavy objects, or even completes a jump, public admiration often focuses on the underlying AI algorithms and intelligent perception. However, beneath all this digital intelligence, the physical entity enabling every precise exertion—the Skeleton of Humanoid Robots—is the true foundation for all movement. This is not a simple metal frame but an engineering marvel that must simultaneously satisfy extreme lightweighting,extraordinary strength and stiffness, and micron-level geometric accuracy.

Traditional manufacturing methods, such as multi-part welding,Splicing, and assembly, can no longer meet the performance demands of this generation of robots. The weight redundancy, strength loss at joints, and inevitable cumulative errors they introduce act like invisible shackles, limiting the robot’s agility and reliability. The key to breaking through this manufacturing bottleneck is a technology that has reshaped the landscape of high-end manufacturing: Five-Axis Linkage Machining.

This article will deeply analyze how GreatLight, as an expert in precision manufacturing, utilizes Five-Axis Linkage Machining technology to “sculpt” highly integrated, high-performance Skeleton of Humanoid Robots from a solid block of material. We will traverse the entire journey from design theory, materials science, and machining processes to final performance validation, revealing why this technology has become the cornerstone for building the next generation of bionic robots.

Part 1: The Stringent Requirements of a Skeleton of Humanoid Robots

More Than a “Metal Frame”: The Three Engineering Paradoxes of a Robot Skeleton

Unlike static industrial frames, the Skeleton of Humanoid Robots is a dynamic load-bearing system. Its design must resolve three core, interrelated paradoxes.

Paradox One: The Eternal Struggle Between Strength and Weight

Every leg lift and arm swing of a robot consumes energy. The weight of the skeleton directly determines the load on the drive components, thereby affecting power consumption and endurance. Therefore, the primary design goal is to pursue an extremely high specific stiffness (stiffness-to-density ratio). This means that while ensuring absolute rigidity, every gram of unnecessary weight must be eliminated. This gives rise to bionic, topology-optimized designs—material exists only along stress paths, with everything else hollowed out. These complex internal cavities and organic shapes are precisely the domain of Five-Axis Linkage Machining.

Paradox Two: Withstanding the Onslaught of Multi-Dimensional complex Forces

A robot’s femur or pelvis does not bear a single force. During walking, running, or falling, they simultaneously experience complex actions of bending, torsion, compression, and impact loads. The Skeleton of Humanoid Robots must, like a bridge engineer designing stress paths, channel these forces efficiently and smoothly to avoid local deformation or instability. This requires a highly integrated structure with internal stiffening ribs and variable wall thicknesses—designs difficult to achieve with traditional three-axis machining or welding processes.

Paradox Three: The “Tyranny of Microns” in Serial Kinematic Chains

A robot’s limb is a serial kinematic chain composed of multiple joints and links. Any micron-level deviation in the flatness, parallelism, or hole position of a Connecting surface will be amplified step-by-step through the chain. This leads to abnormal bearing wear, poor gear meshing, reduced transmission efficiency, and most critically, an irreconcilable discrepancy between the robot’s physical geometry and its digital model in the control software. Therefore, micron-level precision for key interfaces like bearing seats and reducer mounting surfaces is not a target; it is a Survival threshold.

The Limitations and Compromises of Traditional Manufacturing Methods

To understand the necessity of Five-Axis Linkage, one must first see the “ceiling” of traditional methods:

- Cumulative Error from Multi-Part Assembly: Machining the pelvis, hip joint housing, and bearing shell separately and then bolting them together introduces误差 at each mating surface, ultimately leading to misaligned axes and motion jitter.

- Design Compromises: Limited by the Processing angle of three-axis machines, engineers are forced to decompose complex parts into multiple, easily accessible simple parts, sacrificing structural integrity and lightweighting potential.

- Excessive Safety Redundancy: To ensure the strength of parts made with simple processes, wall thickness and material are often Increase, resulting in an “obese” skeleton that sacrifices dynamic performance.

Part 2: Deconstructing the Core Technology of Five-Axis Linkage Machining

What is True Five-Axis Linkage Machining?

Many confuse “five-sided machining” with Five-Axis Linkage Machining. The former is a “3+2” mode where the tool moves with only three linear axes (X, Y, Z) while in contact with the workpiece; the two rotary axes (A, C) are used for positioning and then locked. True Five-Axis Linkage refers to the continuous, simultaneous, and coordinated motion of all five axes under the control of a computer numerical control system during the machining process.

The Coordinated Dance of Motion Axes

- Linear Axes: X (left-right), Y (front-back), Z (up-down) — forming the basis of three-dimensional movement.

- Rotary Axes: A (rotation around X-axis), C (rotation around Z-axis) — enabling the tool to approach the workpiece from any spatial angle.

- Value of Linkage: This allows the tool’s ball nose or side edge to maintain the optimal contact angle with complex curved surfaces, enabling the one-time machining of geometries that previously required multiple setups.

Beyond Hardware: CAM Software and Dynamic Accuracy Compensation

A powerful five-axis machine requires an even more powerful “brain” — Computer-Aided Manufacturing software. Advanced CAM software generates efficient, collision-free complex toolpaths. Meanwhile, the machine’s own dynamic accuracy compensation technology (such as thermal deformation compensation, backlash compensation) is the unsung hero ensuring micron-level precision even during high-speed linkage.

Revolutionary Advantages for Robot Skeleton Manufacturing

1. Single Setup, Achieving Monolithic Integrity

This is the most significant contribution of Five-Axis Linkage Machining to the Skeleton of Humanoid Robots. By completing the vast majority of a part’s features in a single clamping, it thorough eliminates the cumulative error from multiple repositionings. The resulting complex skeletal structure (e.g., a monolithic hip-pelvis composite) possesses unparalleled overall rigidity and dimensional consistency as a single component.

2. Unlocking the Ultimate Form of Topology Optimization

Topology-optimized designs, generated by algorithms with forms resembling biological bones or branches, represent the optimal distribution of material. These “organic forms,” full of curves, negative angles, and internal cavities, are a nightmare for traditional machining but the Natural canvas for Five-Axis Linkage Machining. It allows engineers to boldly pursue ultimate performance designs without compromising for manufacturability.

3. Superior Surface Quality and Tool Life

By maintaining the optimal contact angle between the tool and the machined surface (side milling versus end milling), better cutting conditions are achieved, reducing chatter and yielding a higher surface finish. This is crucial for bearing Mating surface and sealing surfaces requiring high wear resistance and low friction coefficients, while also extending the service life of expensive tools.

Part 3: The GreatLight Precision Manufacturing Protocol: From Digital Model to Physical Reality

Step One: Collaborative Design Optimization

Before the first chip is produced, our engineering team works closely with the client’s design department for Design for Manufacturability (DFM) analysis. We focus not just on “can it be machined” but on “how to machine it better, more economically, and more reliably.” We provide optimization suggestions for the initial design, such as:

- Part Consolidation: Merging multiple assembly parts into a single monolithic structure to enhance rigidity and reduce weight.

- Feature Optimization: Adjusting internal corner radii, depth-to-width ratios to ensure effective tool access and ensure strength.

- Datum Establishment: Jointly defining a clear, robust datum system to ensure the machining and inspection coordinate system completely aligns with design intent.

Step Two: Material Science and Preprocessing

Common materials for Skeleton of Humanoid Robots and considerations:

- Aerospace-Grade Aluminum Alloys (7075-T6, 6061-T6): The mainstream choice. 7075-T6 offers strength near steel and excellent fatigue resistance, making it ideal for primary load-bearing structures. All incoming materials undergo spectroscopic analysis for grade verification and pre-stress relief treatment to prevent subsequent machining distortion.

- Exploratory Materials: For Ultimate performance demands, we have successfully machined Titanium Alloy (TC4) and Magnesium Alloy components. Titanium offers an unparalleled strength-to-weight ratio and biocompatibility; magnesium is even lighter with excellent damping properties but requires special processing and safety protocols.

Step Three: Multi-Stage Five-Axis Linkage Machining

Our machining centers are equipped with high-performance five-axis linkage machines, executing a rigorous process:

- Roughing: Utilizing high-torque spindles to quickly remove the bulk of material, establishing a stable foundation for finishing.

- Semi-Finishing: Further refining the geometry, leaving a uniform, minimal allowance for finishing.

- Precision Five-Axis Linkage Finishing: This is the core stage. Using dynamically balanced high-precision tool holders and cutters, with optimized RPM, feed rates, and depth of cut, the final form is given to critical functional surfaces (bearing bores, mounting faces, seal grooves). On-machine measurement probes periodically and automatically check key dimensions, enabling real-time tool wear compensation.

- Deburring and Cleaning: Precision methods remove all sharp burrs, followed by thorough ultrasonic cleaning to ensure no metal debris remains inside the skeleton’s complex cooling channels or cable conduits.

Step Four: A Comprehensive Dimensional Validation System

Precision lies not only in machining but in verification. We have built a closed-loop quality assurance system:

- In-Process Inspection: Real-time probe measurement during machining is the first line of defense.

- Final CMM Inspection: Each first article and Regularly sampled items undergoes a full-dimensional scan in a temperature-controlled metrology room using a high-precision Coordinate Measuring Machine, generating a detailed inspection report compared against the 3D digital model.

- Surface Roughness and Hardness Testing: Ensuring the surface quality of critical friction pairs and the material heat treatment state meet requirements.

- Data Traceability: All machining parameters, inspection data, and material certificates are recorded and linked to the part’s unique serial number, enabling full lifecycle traceability.

Part 4: The Performance Leap: Tangible Advantages of Five-Axis Monolithic Skeletons

Direct Performance Enhancements

- Weight Reduction up to 20%-40%: Through topology optimization and Precise hollowing out, significant weight reduction is achieved at equal strength, directly improving the robot’s payload capacity, motion acceleration, and operational endurance.

- Stiffness Increase Over 30%: Monolithic structures eliminate microscopic slip and deformation at connection interfaces, resulting in less deformation under load, providing a solid physical platform for high-bandwidth, high-precision force and position control algorithms.

- Transformative Motion Accuracy and Smoothness: Micron-level bearing fit accuracy and zero cumulative assembly error result in lower joint Operating resistance, reduced noise, and more precise positioning.

Long-Term Reliability and Maintenance Costs

- Extended Fatigue Life: Monolithic design avoids stress concentrations in weld heat-affected zones and bolt connections, which are often origins of fatigue cracks. Optimized load paths lead to more uniform stress distribution.

- Significantly Improved Reliability: Fewer parts mean fewer potential points of failure. There is no concern about connecting bolt loosening in a monolithic skeleton.

- Simplified Assembly and Maintenance: What is delivered to the customer is a complete skeletal module that has undergone precision machining and validation, greatly simplifying the robot’s final assembly process and reducing Post-maintenance complexity.

Conclusion: Structural Intelligence — A Partnership Towards Next-Generation Humanoid Robots

Five-Axis Linkage Machining for Skeleton of Humanoid Robots has transcended a mere manufacturing method. It is an enabling technology that transforms the bionic designs born in the digital world into solid, reliable performance carriers in the physical world. It solves not just the problem of “making it” but the challenge of “how to make it Ultimate.”

At GreatLight, we see ourselves as an extension of our clients in the field of “Structural Intelligence.” We provide not just machine time on a five-axis mill, but a complete solution encompassing material understanding, process design, precision manufacturing, and quality assurance. We firmly believe that every skeleton crafted for a top-tier humanoid robot represents a profound dialogue between engineering and manufacturing, a cornerstone pushing the entire industry forward.

When you are committed to breakthrough the boundaries of robotic dynamic performance, a manufacturing partner that pursues perfection at the microscopic scale and dares to innovate at the macroscopic structural level will become your most reliable backbone. Let us common forge the spine of future robots together.

Ready to design the next-generation skeleton for your robotic project? Contact the GreatLight team to start our technical conversation.