Choose the right CNC machining factory for your project: a comprehensive guide

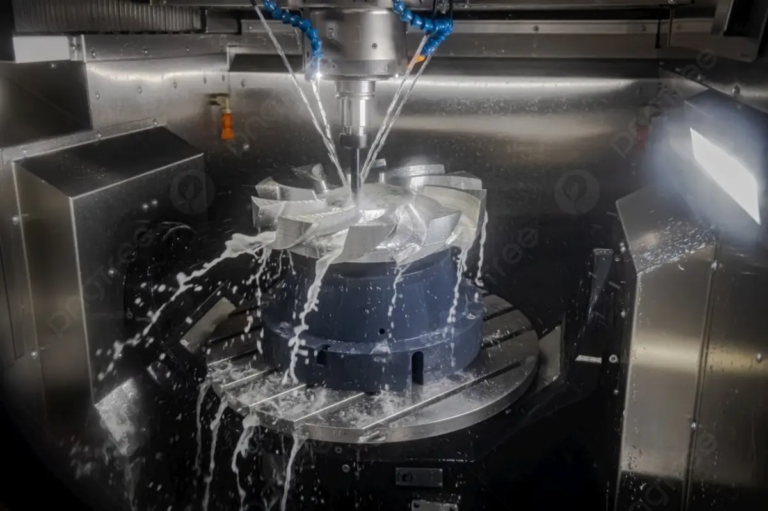

In today’s manufacturing landscape, CNC machining has become an increasingly important technology for the production of high-precision parts and products. With the advent of advanced five-axis CNC machining equipment and production technology, manufacturers can now create complex components with unparalleled accuracy and efficiency. However, with so many CNC machining plants to choose from, choosing the right factory for your project can be a daunting task. In this article, we will provide a comprehensive guide to help you make informed decisions and select the best CNC machining plant for your needs.

What is CNC machining?

CNC machining, also known as computer numerical control machining, is a manufacturing process that uses a computer-controlled machine to remove materials from workpieces to create custom parts or products. This technology revolutionizes the production of complex components, allowing manufacturers to quickly and efficiently produce highly accurate, accurate parts.

Factors to consider when choosing a CNC machining factory

When choosing a CNC processing plant, several key factors need to be considered. Here are some of the most important ones:

- Equipment and technology: Ensure the factory has the latest and most advanced CNC processing equipment to ensure high accuracy and efficiency.

- Capacity and delivery time: Consider the production capacity and lead times of the factory to ensure they meet your project schedule and quantity requirements.

- Materials and Finishes: Check whether the factory can use the required materials and provide the project with the required completion.

- Certification and compliance: Verify that the factory has relevant certifications, such as ISO 9001, AS9100 and ITAR, to ensure compliance with industry standards.

- Experience and expertise: Evaluate the factory’s expertise in using your specific material, geometry, or industry (e.g., aerospace, medical or automotive).

- Communication and collaboration: Evaluate the factory’s communication style and the ability to work with your team to ensure project execution is smooth.

What to look for in a professional CNC machining factory

When searching for CNC machining plants, please look for the following features:

- Advanced equipment and technology

- Experienced and knowledgeable engineers and operators

- Strong quality control and inspection process

- Clear communication and collaboration

- Competing pricing and delivery time

- Well-known certification and compliance

- Good track record of successful projects

Pay attention to red flags

When choosing a CNC machining plant, please be cautious about the following red flags:

- Unrealistic pricing or schedule

- Inadequate quality control or inspection process

- Inexperienced or unqualified persons

- Poor communication or lack of transparency

- Unclear or unverified certification and compliance

Expectations from a first-class CNC machining factory

Reputable CNC processing plants should provide:

- Consistent and high-quality parts

- Competing pricing and delivery time

- Excellent communication and collaboration

- Clear project tracking and updates

- Commitment to meet or exceed customer expectations

Find the ideal CNC processing plant

To find the best CNC machining plant for your project, follow these steps:

- Research and shortlisted for potential factories: Determine the factories that meet your requirements and search for their names online.

- Check out their websites and social media: Evaluate their expertise, equipment and services.

- Request a quote and suggestion: Get detailed quotes and suggestions from the shortlisted factory.

- Evaluation recommendations and records: Carefully evaluate the recommendations and records of candidate plants.

- Take a live visit or factory tour: Assess the operation, equipment and personnel of the plant during a live visit or factory tour.

in conclusion

Choosing the right CNC machining plant for your project can be a complex and time-consuming process. By taking into account the factors outlined above, researching and evaluating potential plants and performing careful evaluations, you can make informed decisions and select the best CNC machining plant for your needs.

FAQ

Q: What are the most important factors to consider when choosing a CNC processing plant?

A: Equipment and technology are essential, but it is equally important to the factory’s capabilities and lead time to ensure they meet your project schedule and quantity requirements.

Q: What certification should I look for in a CNC machining factory?

A: Ensure the factory has relevant certifications, such as ISO 9001, AS9100 and ITAR, to ensure compliance with industry standards.

Q: Can I trust online reviews and recommendations?

A: Online reviews and testimonials may be helpful, but certifications and records can also be verified through other sources for more accurate pictures.

Q: What is the typical lead time for a CNC processing project?

A: Delivery times vary by plant, project complexity and material, but expected delivery times vary from weeks to months.

Q: How to ensure quality control in CNC processing?

A: Find factories with strong quality control and inspection processes and verify these processes with certification, audit and customer reference.