Fast and accurate CNC machining service: what to expect

In today’s fast-paced manufacturing environment, access to reliable and efficient CNC processing services is crucial for companies to stay ahead of their competition. With Great Light’s cutting-edge five-axis CNC machining technology and expertise, you can trust that precision parts will be manufactured quickly and accurately to the highest standards.

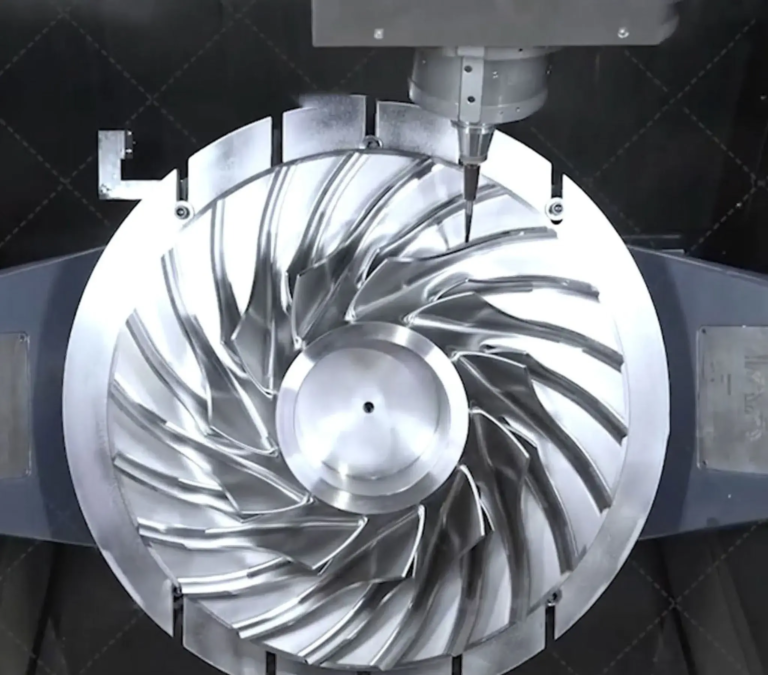

Benefits of five-axis CNC machining

Five-axis CNC machining is a powerful tool for manufacturing complex shapes and sizes with precision and accuracy. Our state-of-the-art five-axis CNC machines are able to handle a wide range of materials, including metals, plastics and composites. This technology enables us to produce complex components with minimal setup and setup time, making it an ideal solution for prototyping and production.

Customized processing solutions

We understand that every project is unique, which is why we offer customized machining solutions to meet your specific needs. Our experienced team will work closely with you to understand the requirements from design to production to ensure your parts are manufactured to the highest standards. Whether you need fast prototyping, production, or post-processing and finishing services, we have the expertise and equipment to deliver excellent results.

Speed up production and reduce costs

With our advanced CNC machining technology, we can accelerate the production process and reduce lead time and costs. Our five-axis CNC machines are designed for high-speed production, allowing us to handle complex parts quickly and efficiently. At the same time, our expertise in production and after-processing ensures that your parts are manufactured to the highest standards, reducing the need for rework, re-grinding or re-processing.

Time-saving and cost-effective solutions

Our customers can expect the following benefits:

- Fast and accurate production time

- Improve accuracy and accuracy

- Customized solutions to meet specific needs

- Minimized rework, re-grinding or re-processing

- Reduce delivery time and cost

in conclusion

From a good point of view, we are committed to providing fast and accurate CNC machining services that meet the highest standards of quality and accuracy. With our cutting-edge technology and team of experts, we are committed to helping our customers achieve their goals, whether it is rapid prototyping, production or post-processing and finishing and finishing. For customized precise processing, high-quality light is the first choice.

FAQ

Q: What types of materials can you deal with?

A: We can handle a variety of materials, including metals, plastics and composites.

Q: How quickly can you turn a project around?

A: Our advanced CNC machines enable us to quickly and efficiently handle complex parts according to the complexity of the project, usually within 1-2 weeks.

Q: What kind of post-processing and completion services do you provide?

A: We offer a range of post-processing and finishing services, including grinding, cutting and polishing to ensure your parts meet the highest standards.

Q: Can you handle large or small volume production?

A: Yes, we can handle small or large-scale production from prototype to production with flexibility and efficiency.

Q: What level of accuracy and accuracy can I expect?

A: Our five-axis CNC machines are designed for high accuracy and accuracy with tolerances of 0.001mm or higher to ensure that your parts meet the highest standards.