In the field of Precision engineering, CNC machining is a key technology to revolutionize the manufacturing landscape. In its various applications, five-axis CNC machining has become an especially complex approach with unparalleled flexibility and precision. For industries requiring complex geometric shapes and high-precision parts, the UK has become a hub for F1 CNC machining services, leveraging state-of-the-art technology to meet the needs of local and international customers. This article delves into the complexity of the UK F1 CNC machining services, highlighting their functions, the materials they can handle and making them a crucial component in the global manufacturing supply chain.

Introduction to F1 CNC machining

F1 CNC machining refers to a computer numerical control machine that can move along five different axes, allowing complex and complex parts to be made in a single operation. This capability greatly reduces production time and improves the accuracy of the final product. the term "F1" The high speed and high precision nature of these services is often emphasized, similar to the accuracy and speed required for Formula One racing.

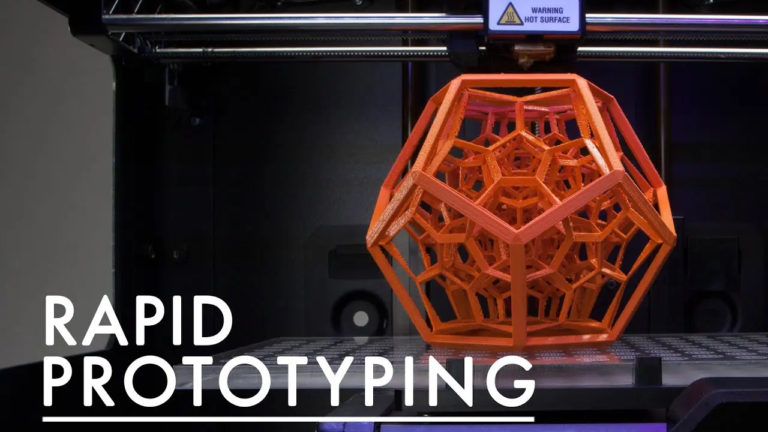

Advanced equipment and technology

The backbone of the UK F1 CNC processing service is advanced equipment and production technology. Manufacturers have invested heavily in state-of-the-art machinery that can perform complex instructions with micron-scale accuracy. This combination of machinery and complex software can produce parts with complex designs, which cannot be achieved by traditional machining methods. Furthermore, these services are not limited to metal parts. They can also handle a wide range of materials, including plastics, wood and composites, making them used in a variety of industries.

One-stop post-processing and completion service

In addition to the initial processing process, F1 CNC machining services in the UK usually offer one-stop post-processing and completion services. This includes heat treatment, anodization, painting and assembly, etc. By providing these comprehensive services, manufacturers can ensure that their products are not only manufactured accurately, but also fully functional when delivered. This comprehensive one-simplifies the supply chain, reduces lead times and improves overall production efficiency.

Customization and quick turnaround

One of the most compelling aspects of F1 CNC machining services is their ability to customize parts according to specific customer needs. From prototype development to mass production, these services can be adapted to meet the needs of customers in different fields, including aerospace, automotive and healthcare. Furthermore, with the integration of advanced technology and streamlined processes, these services can provide fast turnaround times without compromising quality, making them ideal for projects with tight deadlines.

Materials and Applications

The versatility of the UK F1 CNC machining service is also reflected in the range of materials they can handle. From aluminum and stainless steel to titanium and exotic alloys, the ability to use a wide range of materials makes these services invaluable for industries where specific materials are required. From engine components and aerospace parts (requires high strength-to-weight ratios) to applications of medical implants and surgical instruments (biocompatibility and accuracy are critical).

in conclusion

The UK’s F1 CNC machining service represents the pinnacle of precision engineering, combining advanced technology, versatility and commitment to quality. These services are able to produce complex parts with high precision and speed, not only crucial to the local industry, but also play an important role in global manufacturing. Whether used for prototyping, production of complex parts or customized precision machining, the UK’s F1 CNC machining department stands out as a leader, providing innovative solutions to meet the evolving needs of various industries.

FAQ

What is five-axis CNC machining?

- Five-axis CNC machining refers to a manufacturing process involving the use of computer-controlled machines that can move along five different axes, allowing for the creation of complex parts with high precision.

What materials can be processed through F1 CNC machining?

- F1 CNC machining services can handle a wide range of materials including metals (such as aluminum, steel and titanium), plastics, wood and composites.

What industries have benefited from F1 CNC processing services?

- Due to the accuracy, speed and customization provided by these services, a variety of industries including aerospace, automotive, healthcare and manufacturing industries are benefiting.

What post-processing services are usually provided?

- Common post-treatment services include heat treatment, anodization, painting and assembly, providing customers with a comprehensive solution from processing to finishing.

- How does F1 CNC machining service ensure accuracy and quality?

- Ensure that all parts meet the required accuracy and functional standards by using advanced equipment, sophisticated software and compliance with strict quality control measures.