Unlock the Full Potential of 5-Axis Machining Centers: Revolutionizing Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the technology of 5-axis machining centers has emerged as a game-changer, poised to revolutionize the way we produce complex components and parts. With its unparalleled precision, flexibility, and speed, this cutting-edge technology has captivated industry professionals and manufacturers worldwide. In this blog post, we will delve into the world of 5-axis machining centers, exploring its limitless potential, advantages, and best practices, helping you unlock the full potential of this innovative technology.

Breaking Down Barriers

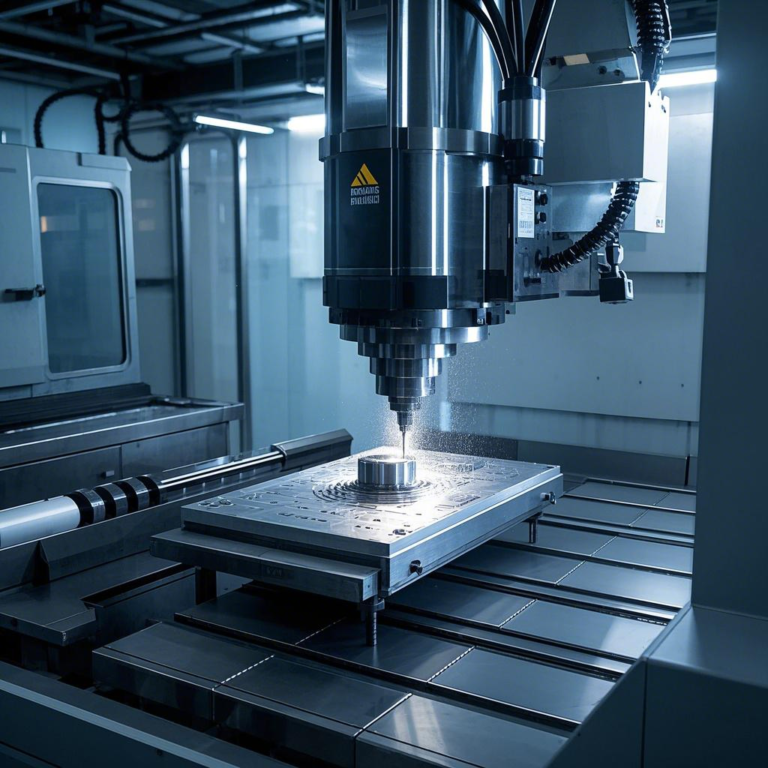

Traditional 3-axis machining centers have long been the norm, but they often struggle with complex curved surfaces and polyhedral parts, leading to lengthy setup times, reduced precision, and elevated risk of errors. The 5-axis machining center, on the other hand, takes this challenge head-on by introducing two additional axes of rotation, empowering the tool to adapt to even the most intricate designs. This breakthrough technology condenses production cycles, streamlining the process while ensuring exceptional accuracy and surface quality.

Industries that Benefitted the Most

From aerospace to automotive, medical devices to precision molds, the 5-axis machining center has made a significant impact across various industries. In the aerospace industry, for instance, the 5-axis machining center has enabled the production of complex engine blades and features, boasting high-precision, reliable, and efficient operation. In the automotive sector, these centers have streamlined the manufacturing of complex automobile molds, cutting down on production cycles while boosting component quality.

Advantages Galore

So, what makes 5-axis machining centers stand out from the rest? Here are just a few benefits that set them apart:

- Improved Production Efficiency: By performing multiple tasks in a single setup, the 5-axis machining center reduces idle time, labor, and machine downtime, ultimately increasing output per unit of time.

- Enhanced Precision: With its advanced movement control and high-precision machining capabilities, the 5-axis machining center guarantees exceptional accuracy, minimizing the risk of defects and rework.

- Increased Productivity: Automating complex tasks, these machines reduce manual intervention, making them perfect for high-volume, high-precision production environments.

- Intelligent Technology: As technology continues to evolve, the 5-axis machining center becomes increasingly intelligent, enabling operators to start using it with ease after minimal training.

Best Practices for Getting the Most Out of 5-Axis Machining Centers

To fully harness the power of 5-axis machining centers, it’s essential to follow these best practices:

- Rational Tool Selection: Choose the right tools for the job, tailoring them to the specific material and treatment requirements.

- Regular Equipment Maintenance: Regularly maintain your equipment to ensure precise movement and reduced downtime.

- Continuous Training and Development: Stay up-to-date with the latest techniques and technologies to maximize productivity and profitability.

Conclusion

As the manufacturing landscape continues to evolve, the 5-axis machining center has emerged as a crucial tool for driving innovation, efficiency, and precision. By understanding the benefits and best practices associated with this technology, manufacturers can unlock new opportunities for growth, stay ahead of the competition, and drive long-term success. As we look to the future, the 5-axis machining center will undoubtedly remain a key player in shaping the manufacturing industry, empowering companies to produce high-quality products with increased speed and precision.