introduce

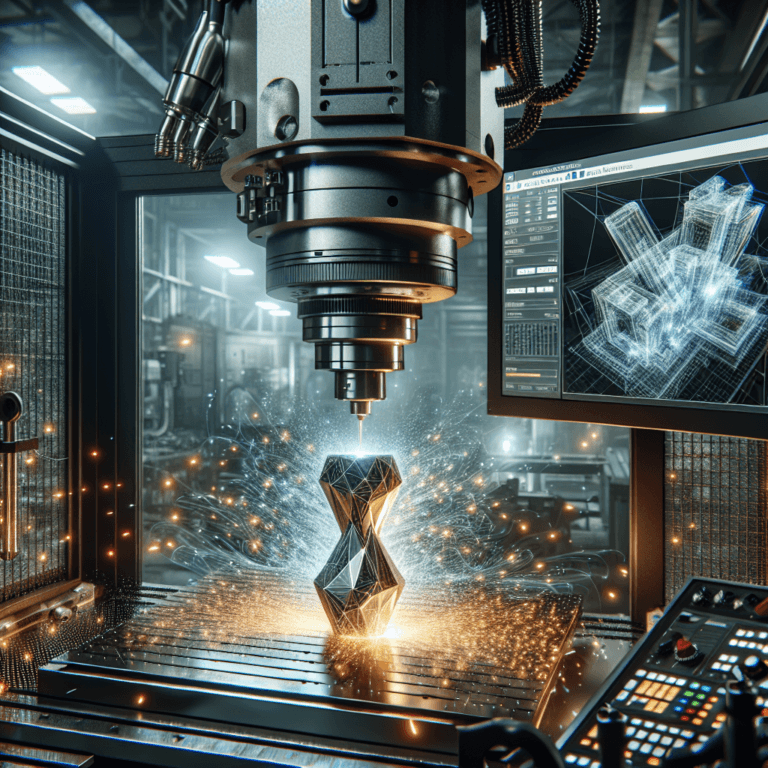

In today’s rapidly developing industrial landscape, precision manufacturing has become an important cornerstone in various fields such as aerospace, automotive, medical and electronics. At the heart of this evolution is CNC milling technology, an innovative method that can produce complex parts with precise accuracy and repeatability. CNC, or computer numerical control, refers to the automated control of processing tools through computers. This article explores the scope of CNC milling machine services, allowing users to understand not only the basic mechanics involved, but also their advantages, applications and future prospects in precision parts manufacturing.

Learn about CNC milling

What is CNC milling?

CNC milling is a subtractive manufacturing process that uses rotating tools to remove material from a workpiece. Unlike traditional milling, which relies heavily on manual operations, CNC milling uses computer technology to automate the milling process. This enables manufacturers to create highly detailed and complex assemblies with minimal human intervention, resulting in greater efficiency, less waste and greater precision.

Mechanics of CNC Milling

At the heart of CNC milling is a controlled environment that enables the machining tool to perform planned operations with high precision. The process proceeds through the following basic steps:

design stage: Engineers create 3D CAD (computer-aided design) models of the required parts. The model serves as a blueprint for the milling operation.

Convert to CNC code: The CAD model is then converted into a CNC program using CAM (Computer Aided Manufacturing) software. This program generates G-code, a language that the CNC machine understands.

set up: The CNC machine is ready for operation, with the workpiece firmly clamped to the machine bed to prevent movement.

machining process: The CNC milling machine executes the command specified by G code. It involves a series of motions in which the tool rotates and traverses the workpiece, cutting the material and shaping it to specifications.

- finishing: After the milling process is complete, the part may undergo secondary operations (such as polishing, anodizing, etc.) to achieve a final finish and enhance performance.

Types of CNC milling machines

There are many types of CNC milling machines, each tailored for a specific application:

Vertical CNC milling machine: These machine tools have a vertical spindle, which means the cutting tool is placed vertically above the workpiece. They are often used to produce parts that require fine machining.

Horizontal CNC milling machine: These machine types feature a horizontal orientation that allows for more powerful cuts and are typically used on larger workpieces.

- 5-axis CNC milling machine: These advanced machines can manipulate workpieces in multiple axes simultaneously, enabling the creation of highly complex geometries.

Advantages of CNC Milling

The integration of CNC milling in the manufacturing process offers many advantages:

1. Precision and accuracy

One of the most important advantages of CNC milling is its ability to achieve unparalleled precision. CNC machines operate within tight tolerances, ensuring every part produced meets exacting specifications. This level of accuracy is essential for the industry, as even small deviations can lead to catastrophic failure.

2. Repeatability

CNC milling systems can produce identical parts at scale with remarkable consistency. This repeatability is critical for manufacturing processes that require high-volume production without compromising quality.

3. Complex geometric shapes

CNC milling technology can efficiently produce complex shapes and complex designs that are labor-intensive or impossible to create manually. This versatility opens up new design possibilities for engineers and product developers.

4. Material versatility

CNC mills can machine a variety of materials, from soft plastics to tough metals like titanium and steel. This adaptability enables manufacturers to select the best material for a specific application.

5. Reduce human error

Automation minimizes the possibility of human error, thereby improving the overall quality of produced parts. Workers can focus on higher-level tasks, such as programming and quality assurance, rather than manual machine operations.

CNC milling applications

CNC milling is used in numerous fields due to its versatility and precision. Main applications include:

1.Aerospace industry

In aerospace manufacturing, precision is critical. CNC milling machines are used to produce parts that require extremely tight tolerances, such as engine mounts, brackets and housings.

2. Automobile manufacturing

The automotive industry utilizes CNC milling for prototyping and high-volume production. Critical components such as gearboxes, brackets and engine components benefit from the precision of CNC machines.

3. Medical device manufacturing

The medical field requires specialized components, often with complex designs, such as surgical instruments and implantable devices. CNC milling ensures these parts meet strict regulatory standards while remaining functional.

4. Electronics and Telecommunications

CNC milling plays an important role in the production of housings, circuit boards and connectors, where precise alignment is critical to performance.

5. Mold making

CNC milling plays a vital role in mold manufacturing, allowing manufacturers to create molds with complex geometries and high precision for injection molding and casting processes.

The future of CNC milling

As technology advances, the capabilities of CNC milling machines continue to evolve. Here are some of the key trends shaping the future of this manufacturing technology:

1. Integration of artificial intelligence and machine learning

The combination of artificial intelligence (AI) and machine learning algorithms enhances the decision-making process within CNC machine tools. For example, predictive maintenance can reduce downtime by anticipating equipment failures before they occur.

2. Additive manufacturing integration

Synergies between CNC milling and additive manufacturing are becoming increasingly common. This hybrid approach enables manufacturers to produce parts that benefit from the advantages of both subtractive and additive processes, allowing for optimal design and material efficiency.

3. Enhanced software features

Advances in CAM software have made part design more complex and improved simulation capabilities. This allows for real-time adjustments and optimization during the manufacturing process.

4. Sustainable practices

As industries strive to become more sustainable, CNC milling processes are constantly being optimized to reduce waste and energy consumption. Innovations in tooling and processing strategies can improve the efficiency of material use and align production practices with environmental goals.

in conclusion

Exploring CNC milling machine services reveals endless possibilities for precision part manufacturing. From understanding basic mechanics to recognizing the benefits and diverse applications of CNC milling, it’s clear that this technology plays a key role in driving industrial innovation. Going forward, continued advances in technology are expected to increase the efficiency and capabilities of CNC milling, ensuring its relevance in an evolving manufacturing environment. So whether you’re a manufacturer, engineer or product designer, using CNC milling services can take your projects to new levels of precision, efficiency and success.

FAQ

What is CNC milling and how does it work?

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to precisely remove material from a workpiece. It involves designing a CAD model, converting it into CNC code using CAM software, and then performing machining operations.

What materials can CNC milling machines process?

CNC milling machines can process a variety of materials, including metals such as aluminum, steel, titanium and copper, as well as plastics and composites.

How accurate is CNC milling?

CNC mills can achieve tolerances as tight as +/- 0.001 inches, depending on the machine and tooling used, making them suitable for high-precision applications.

Which industries benefit the most from CNC milling?

Due to the high precision and complexity of the parts produced, CNC milling is widely used in aerospace, automotive, medical device manufacturing, electronics, mold manufacturing and other industries.

What are the typical costs associated with CNC milling services?

The cost of CNC milling services can vary greatly depending on factors such as material selection, design complexity, production volume, and additional finishing processes. It is always recommended to consult the service provider directly to obtain accurate pricing based on specific project requirements.

Can CNC milling be used for prototyping?

Yes, CNC milling is an excellent choice for prototyping because of its ability to quickly create high-precision models and parts that facilitate design verification and modification before moving into full production.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.