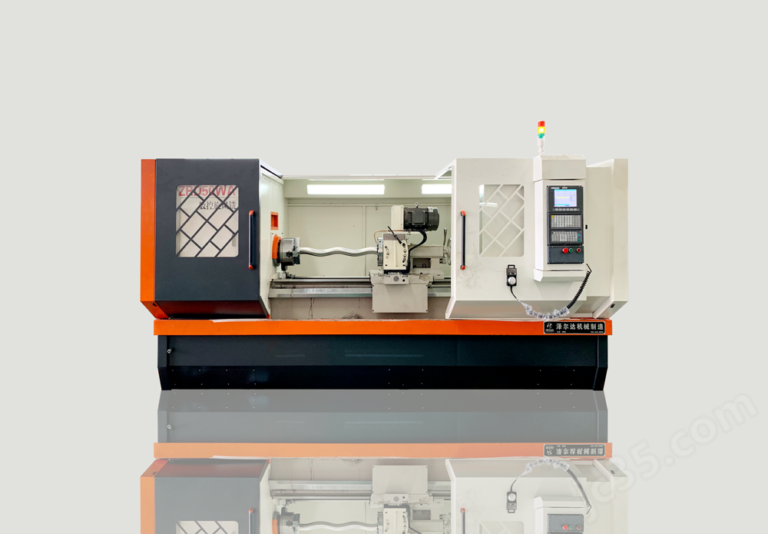

Unlocking the Full Potential of CNC Cyclone Milling Machines in Complex Part Processing

In today’s fast-paced manufacturing industry, the demand for high-precision and efficient parts has never been higher. With the rapid advancement of CNC cyclone milling machines, manufacturers can now achieve complex part processing with unparalleled precision and speed. In this article, we’ll delve into the technical characteristics, application scenarios, and actual processing effects of CNC cyclone milling machines, and explore their vast potential in transforming the manufacturing landscape.

Technical Characteristics: The Foundation for Precision

The CNC cyclone mill is a cutting-edge machine that combines high-speed rotary tools and CNC systems for precision processing. Its main technical characteristics include:

- High Efficiency: With high-speed rotary tools, the cyclone milling machine achieves high precision cutting and significantly improves treatment efficiency.

- Automatic Tool Change: The machine is equipped with an automatic tool change system, allowing for seamless tool changes and compensations, further enhancing efficiency and precision.

- Multi-Axis Link Machining: The machine supports multi-axis link machining, allowing for the machining of multiple areas in a single tightening, reducing positioning errors and cumulative errors.

- Precise CNC Control: The machine’s precise CNC control ensures machining accuracy at the micron level, meeting the stringent requirements of complex part processing.

Application Scenarios: Unlocking the Power of Complex Part Processing

CNC cyclone milling machines have vast application perspectives in complex part processing, with the following key areas:

- Aerospace Industry: Aerospace parts often require complex shapes and high precision, making the cyclone milling machine an ideal choice for processing engine blades, turbine discs, and other critical components.

- Automotive Manufacturing: Complex automobile parts, such as engine cylinder blocks, vilellers, and other precision-coupled surfaces, can be effectively machined using the cyclone milling machine.

- Mold Manufacturing: The machine’s high-precision machining capabilities and surface finish quality make it an excellent choice for mold manufacturing, ensuring precise and repeatable part production.

- Medical Devices: Complex medical devices, such as artificial joints, surgical tools, and other precision-critical components, can benefit from the cyclone milling machine’s high-precision machining capabilities and surface finish quality.

Actual Machining Efficiencies: Driving Innovation in Complex Part Processing

In actual processing, CNC cyclone milling machines have demonstrated significant treatment effects, including:

- High Precision Machining: The machine’s precise CNC control ensures machining accuracy at the micron level, making it an ideal choice for processing complex parts with high precision requirements.

- High Efficiency Machining: The machine’s high-speed rotary tools and automatic tool change system enable efficient machining, reducing production time and increasing productivity.

- Multi-Axis Link Machining: The machine’s multi-axis link machining capabilities allow for the machining of multiple areas in a single tightening, reducing positioning errors and cumulative errors.

- Excellent Surface Quality: The machine’s high-precision machining capabilities and surface finish quality ensure excellent surface quality, meeting the stringent requirements of complex part processing.

Conclusion: Unlocking the Full Potential of CNC Cyclone Milling Machines

CNC cyclone milling machines have truly revolutionized complex part processing, offering unparalleled precision, efficiency, and surface quality. With their vast application perspectives and actual processing effects, these machines are set to play a vital role in driving innovation in the manufacturing industry. As the industry continues to evolve, one thing is clear: CNC cyclone milling machines will be at the forefront of tomorrow’s manufacturing landscape.

Feel free to comment, share, and explore more on the subject!