As various industries increasingly adopt magnesium as a material to take advantage of its lightweight, strong and durable properties, it is essential to understand the complexities of safely processing this metal.

The highly flammable nature of magnesium, combined with the danger of its dust and debris, makes it an extremely difficult material to work with.

1. Introduction to magnesium and its unique properties

Often considered the lightest of all structural metals, magnesium has many unique properties that make it a preferred choice in various industries. Magnesium is approximately two-thirds denser than aluminum, providing significant weight savings – a highly sought-after advantage, particularly in the aerospace and automotive industries, for improved fuel efficiency.

However, not only is magnesium light, but its excellent processability further increases its demand. However, these desirable properties come with inherent challenges, including their high flammability and susceptibility to rapid oxidation. It is essential to exploit these attributes to maximize their potential while ensuring security.

2. Understand the risks of magnesium treatment

1. Magnesium is highly flammable

Although magnesium is valued for its lightness and maneuverability, it also carries an inherent risk: it is highly flammable. Magnesium can ignite when exposed to air, especially at high temperatures or when ground into fine particles. This potential for self-ignition presents significant risks during processing, as the metal produces intense white flames that are difficult to extinguish by traditional methods and therefore require special safety precautions.

2. The harms of magnesium powder and magnesium shavings

The inherent flammability of magnesium is not the only concern; processing also creates potentially explosive dust and discrete magnesium shavings. When these particles accumulate, even a small ignition source can cause an explosion. Therefore, careful management and regular cleaning of magnesium byproducts is essential to ensure a safe processing workplace.

3. Basic Safety Tips for CNC Processing of Magnesium Alloys

1. The importance of machine maintenance and regular inspections

When machining magnesium, maintaining the integrity of your CNC machine is essential. Over time, wear and tear can compromise safety, especially when magnesium residue builds up inside machine parts. If these residues come into contact with sparks or high temperatures, they may become a source of ignition. It is essential to regularly inspect your CNC machine for mechanical wear and potential magnesium buildup. Regular maintenance ensures proper machine operation and minimizes the risk of accidental ignition, protecting equipment and personnel.

2. Use protective covers to prevent sparks and fires

During “magnesium machining”, sparks are particularly dangerous due to the high flammability of the material. The use of protective covers is essential to protect the processing area. These barriers can trap and divert sparks, especially away from areas where “magnesium shavings” might accumulate. Additionally, they can limit potential outbreaks and prevent their escalation. This approach may improve safety when processing magnesium.

3. Safe handling and disposal of magnesium shavings

Magnesium shavings and residues pose significant risks after processing. If left unchecked, these particles can easily catch fire. They should be handled with extreme caution. This debris should be collected regularly using non-static tools and equipment to prevent accumulation. After collection, they must be disposed of in sealed metal containers, which avoids accidental fires caused by external factors. Proper controls and prompt handling can mitigate potential hazards, ensure a safer processing environment and prevent environmental impacts.

4. Avoid using specific cutting fluids which may increase the risk of fire

Cutting fluids are essential in many machining processes, but when dealing with magnesium, they require special attention. Some cutting fluids can increase the flammability of magnesium, making the situation more unstable. It is essential to use a light mineral oil or other cutting fluid specifically designed for magnesium machining.

4. What are the advantages of CNC processing of magnesium?

Despite the risks associated with CNC machining of magnesium, the benefits are clear. Magnesium’s lightweight properties, excellent surface finish and excellent machinability make it ideal for CNC machining under strict safety measures.

1. Lightweight Features

Magnesium is one of the lightest structural metals available. This lightweight property means that magnesium components can significantly reduce the overall weight of the product. Magnesium parts are highly sought after, particularly in the aerospace and automotive industries, because their reduced weight improves fuel efficiency and performance.

2. High strength-to-weight ratio

Although magnesium is lightweight, it does not compromise its strength. It features an excellent strength-to-weight ratio, meaning the product maintains its structural integrity and durability even when using thinner magnesium parts, saving material and reducing weight.

3. Excellent processing performance

Magnesium is easier to process than many other metals. This cuts faster and requires less power. This can shorten production cycles, reduce tool wear and reduce costs during machining.

4. Good thermal conductivity

Magnesium conducts heat better than many other metals, including aluminum. This makes it an excellent choice for components requiring efficient heat dissipation, such as electronic enclosures or automotive components.

5. Shielding against electromagnetic interference (EMI)

Magnesium has natural shielding properties against EMI and radio frequency interference (RFI). In the era of ever-increasing electronic integration, parts machined with magnesium can help protect sensitive electronic equipment from external interference.

6. Environmental benefits

Magnesium is abundant and recyclable without loss of quality. Magnesium processing produces fewer emissions and uses less energy than other metals. Additionally, due to its natural abundance, the use of magnesium can be considered a sustainable option, ensuring a lower industrial carbon footprint.

7. Multifunctional finish

Magnesium alloy parts can be easily finished using a variety of methods, including painting, electroplating, or anodizing. This flexibility allows manufacturers to achieve the desired aesthetic and functional finishes to meet specific product requirements.

Therefore, incorporating magnesium into the material via CNC machining can provide manufacturers with multiple performance, aesthetic and environmental benefits, making it a first choice for many applications.

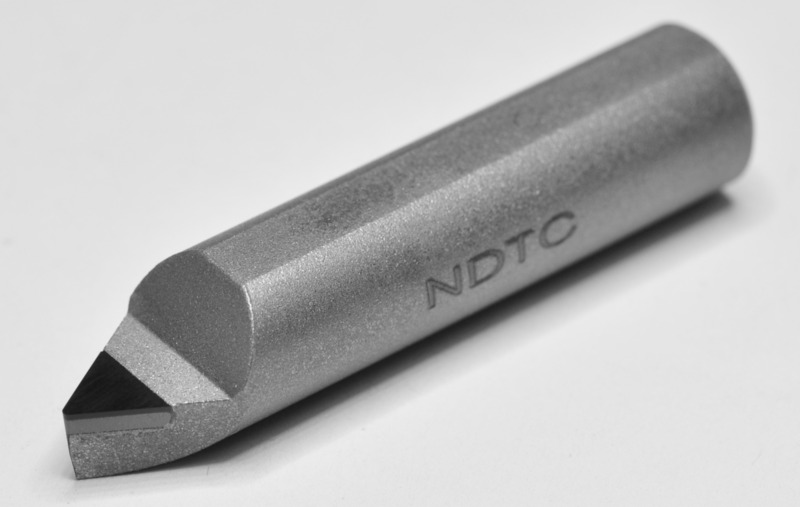

5. Choose the right CNC tool

Choosing the right CNC tool is crucial for machining magnesium alloys. Using sharp knives is essential to avoid heat buildup. The following tools are commonly used in magnesium machining.

1. High speed steel tools

High speed steel (HSS) cutting tools are flexible and inexpensive. Their robustness means they resist pressure and can withstand interrupted cuts. They are also easily resharpenable and suitable for a variety of applications.

2. Carbide cutting tools

Carbide cutting tools are harder than high speed steel and have better wear resistance. This allows them to stay sharp longer and provide a better surface finish. They can also operate at higher processing speeds, increasing productivity.

3. Coated carbide cutting tools

These tools combine the benefits of carbide with special coatings such as titanium nitride to further increase surface hardness and heat resistance. The result is extended tool life, increased machining speed and improved surface finish.

4. Polycrystalline Diamond (PCD) Cutting Tools

PCD cutting tools are one of the hardest cutting materials and have excellent wear resistance. They can be processed at extremely high speeds and remain sharp for long periods of time, making them ideal for stable, high-volume production.

CNC machining of magnesium alloys produces parts that are lightweight, strong, uniform in size and impact resistant. Magnesium alloys have impressive machinability and can be used in various applications using various CNC processes. However, processing magnesium alloys poses safety risks. Therefore, a thorough understanding of magnesium alloy processing is crucial for operational safety.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.