Which will you choose, learning programming or programming?

Many children in rural areas cannot get into college because their families are poor and have no money. Me too, although my education is not very high, it does not affect our own life. fate. The way to survive is actually not scary if you don’t have a degree, it’s just that you don’t have the heart to change the current situation. With a mindset, society is the best school. We can learn more about more practical and cruel realities and truths in society when we are not in school. Many people will choose to enter a factory as a first step and become a machine operator. apprentice., The starting point is good. When you are young, you should become an adult and you should contribute to the family. You shouldn’t sit idle every day and do nothing.

In fact, many people will think so. What is cruel is human perseverance. Many people stop there, are content with the status quo and don’t want to progress. Do you want to spend your whole life playing tricks, without any growth. , no progress and no future? Think about it, as the saying goes, water only flows to the lowest places, and people look higher. Science and technology are progressing, and times are moving forward. We cannot survive if we settle for the status quo.

Although we do not have any college degrees, we enter society as early as possible, understand the cruelty of society, and understand the difficulties and difficulties of life. In the world of people like us, there is not a step upwards, only downwards. -to the earth, and we can learn the knowledge that we do not have. Maybe I’m still here today. After working hard in the factory, I became a programmer the next year, and a programming master the following year. we are no worse than those who have higher education. What I fear is that we don’t have confidence and we don’t have goals.

If we’re still working on the machine, let’s plan our own programming path! If you show determination, take action and put in the effort, the rewards will be inevitable. Therefore, from my personal experience, I suggest that all colleagues who are currently working in CNC should do their best, strive for excellence and strive to acquire some of the knowledge required in this industry . Every day you will be a whole new person. A better self.

In actual work, few people use macro programs to automatically input the values of coordinate coefficients and tool length compensation. Today, Yuange will share this “long lost” method. In fact, it has many advantages, including safety and high efficiency. . If the machine tool is equipped with an automatic tool adjustment device, which can realize continuous tool adjustment, it will be very cool. Come try it now!

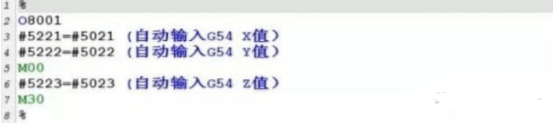

Coordinate system autofill method:

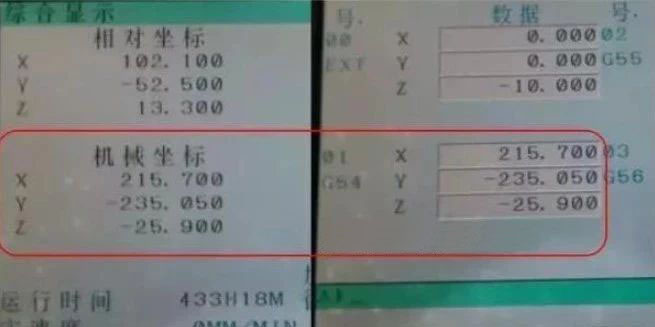

1. Run this program and the mechanical coordinate values will be automatically entered into G54 X, Y, Z as shown below:

2. The results are displayed as shown below:

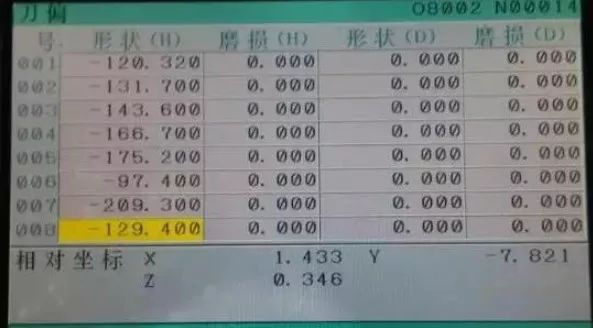

Tool length compensation automatic input method:

1. Taking our company’s 12 tool magazines as an example, run this program and the Z value of the mechanical coordinate will be automatically input into the tool length compensation, as shown below:

2. Displaying results:

How to go from technical engineer to technical manager as quickly as possible?

1. Examine the problem and learn to change from one point to another.

Engineers tend to be single-minded and don’t approach problems holistically. They often analyze and solve problems only from a technical perspective, but often don’t have a good understanding of the big picture and can’t step outside the technical level to look at them. the problems in a broader perspective. As a result, it is easy to get stuck, resulting in problems not being resolved well. Leaders, on the other hand, often have broad vision and quick thinking. They can step out from the technical level and analyze and solve problems from different angles.

2. Stop being self-centered and think altruistically.

When you’re an engineer, you only have to keep your own third of an acre of land. As a department head, you need to focus more on your subordinates. For example, you must provide support and help your subordinates with their tasks. to work. Grow and work for the benefit of your subordinates. For your subordinates, you are like their older brother, you must be caring, responsible and responsible.

3. Stop being competitive and learn to admit defeat when appropriate.

People who are used to being engineers often have “damn self-confidence” and have a kind of “contempt for ordinary people” from the bottom of their hearts. Even if they drink three kilos of Erguotou, they will not accept it (without support). If they want to become managers, they need to get rid of this bad habit, and in the right way. Sometimes you have to learn to admit defeat. You can say something like this: “Lao Wang, your plan is better than mine. If you make a few adjustments here, it will be perfect. You can achieve your goal by affirming the other party. first, then express your opinions. There is no need to follow. The subordinates were so angry that their faces were red.

4. Stop doing everything yourself and learn to be a “hands-off trader.”

When you were an engineer, you were used to doing everything yourself, but once you move into management, you don’t have as much energy to implement everything one by one. At that point, you need to learn to be a “hands-on.” “outside the boss” and fully empower your subordinates so that they can earn respect. A sense of responsibility and trust can stimulate subordinates’ work enthusiasm to the greatest extent and give them a greater sense of accomplishment.

5. In addition to learning to do, you must also learn to “show”.

Most engineers have a common problem, that is, they like to immerse themselves in research and are not good at verbal expression, just like “when boiling dumplings in a teapot, none of them can be paid. management, you need to improve your speaking skills, so that you can make your good performance even better, and even make your poor performance shine. Some people may think it is deceptive, but in fact it is not a fabrication, but an excellent one. language. The ability to express yourself is also an important ability to be a leader.

6. Don’t just talk, but take the lead in facing difficulties.

As a subordinate, the most annoying leader is the one who stands up and speaks painlessly. As a qualified manager, when faced with difficulties, you must learn to lead by example. When the subordinates see the leader, they rush to the front, which will do it. certainly increase their morale.

7. Externally, learn to protect your subordinates from their faults, and internally, learn to teach behind closed doors.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.