The European Space Agency (ESA) has reached a major milestone in space manufacturing, successfully 3D printing the first metal part in space. The metal 3D printer, developed by Airbus and partners, was launched to the International Space Station (ISS) earlier this year and installed on the Columbus module by ESA astronaut Andreas Mogensen. In August, the printer printed the first metal part in 3D in a microgravity environment.

ESA has successfully printed the first metal part in space.

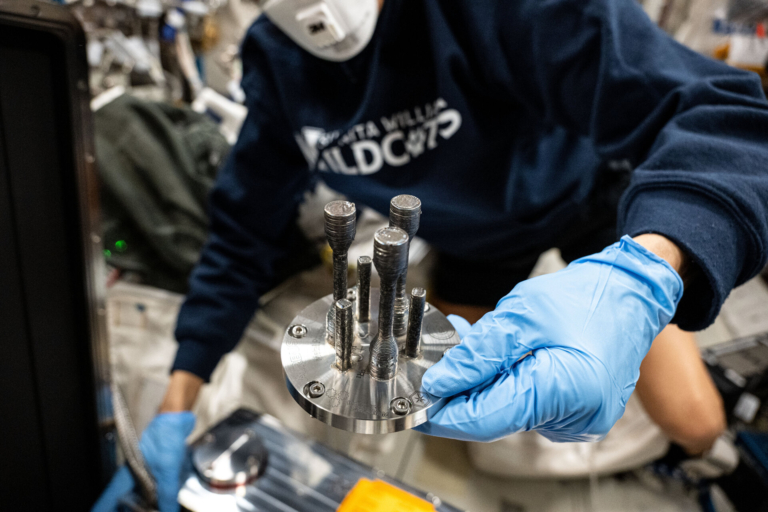

ESA used a metal 3D printer on the International Space Station to print the first metal part in space, demonstrating successful manufacturing in a microgravity environment. Image source: ESA/NASA

Return to Earth for mass analysis

ESA plans to send this first product, along with three other printed parts, to Earth for extensive quality testing. Two of the printed parts will be sent to the ESA Technology Center (ESTEC) in the Netherlands, one will be used in the LUNA facility at the European Astronaut Center (EAC) in Cologne and the last one will be analyzed by the Technical University. of Denmark (DTU). These tests will provide important data on the quality of 3D printing in space.

Additive manufacturing is essential to future space missions

As missions to the Moon and Mars become more frequent and more complex, resupplying spacecraft will become increasingly difficult. Additive manufacturing in space offers a solution that allows astronauts to manufacture necessary parts, repair equipment and produce specialized tools as needed. This reduces the need for resupply missions and increases space crew autonomy, a key advantage for long-duration missions far from Earth.

ESA’s metal 3D printer is the first to successfully operate in microgravity, building on previous efforts to 3D print plastics on the International Space Station. This achievement marks a new frontier in space exploration and demonstrates the potential of in-space manufacturing to support long-duration missions.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.