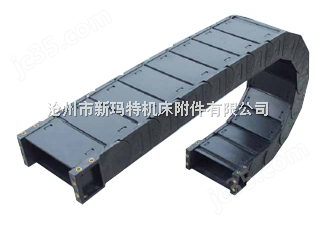

The Ultimate Guide to End Stops: Uncovering the Power of Fully Closed Drag Chains in Modern Mechanical Equipment

As the foundation of any mechanical system, cables, oil pipes, and gas pipes are vulnerable to damage caused by environmental factors, motion, and vibration. To address this, manufacturers require a reliable and robust solution to protect these sensitive components. That’s where fully closed drag chains come in. In this article, we’ll delve into the world of fully closed drag chains, exploring their design philosophy, benefits, and applications in various industries.

Design Philosophy: A Shield for the Senses

Fully closed drag chains are an ingenious solution, specifically designed to safeguard these critical components from external interference. By isolating the external environment and creating a solid housing, these chains ensure that cables and other components operate stably and safely in complex, variable motion environments. The drag chain’s robust structure, made from high-quality materials, can withstand significant forces, mechanically and physically protecting the cable.

Benefits of Fully Closed Drag Chains

- Complete Protection: The housing effectively shields cables and other components from external interference, allowing for reliable performance and reduced downtime.

- Robust and Durable: The high-quality materials used to construct the chain provide exceptional mechanical properties and maintain stable performance under harsh operating conditions.

- Flexible Adaptability: While offering complete protection, the drag chain design allows for flexible movement and versatility, enabling easy installation and maintenance.

Practical Advantages

Easy Installation: Repair and replacement of cables and other components is simplified, thanks to the drag chain’s practical design, which permits easy access and closure.

Widespread Adoption

The benefits of fully closed drag chains have earned them a prominent place in various industries, including:

- CNC Machines: Fully closed drag chains ensure efficient, high-quality production and precision movement.

- Automated Production Lines: Effective cable management and protection guaranty uninterrupted workflow.

- Robot Systems: Accurate and constant performance is vital for robotic systems, where fully closed drag chains play a crucial role.

- Aerospace: In aerospace, the reliability and performance of fully closed drag chains are critical for ensuring safe and efficient operations.

- Automotive Manufacturing: High-quality production lines rely on these chains to protect vital components and cables.

- Food Processing: In food processing, maintaining a clean and sanitary environment is crucial; fully closed drag chains help ensure this.

Conclusion

In conclusion, fully closed drag chains have established themselves as essential components in modern mechanical equipment. By providing complete protection, robust design, flexible adaptability, and easy maintenance, these chains have become the go-to solution for industries seeking reliable and efficient operations.