3D printing has transformed various industries, providing possibilities ranging from creating prototypes to developing complex biomedical structures. Among current methods, DLP has become a popular technology due to its speed and accuracy. However, this technology also has drawbacks, including material uniformity and heat dissipation, but this is likely changing. Researchers at the University of Melbourne have developed an innovation that could transform the future of bioprinting: dynamic interface printing (DIP).

Nature magazine recently published an article on newAn article on the DIP method, which proposes an innovative approach by moving the printing point towards the meniscus or superficial curvature of the precursor liquid. This strategic change improves material flow control and optimizes heat dissipation, two important aspects of fast, high-precision 3D printing.

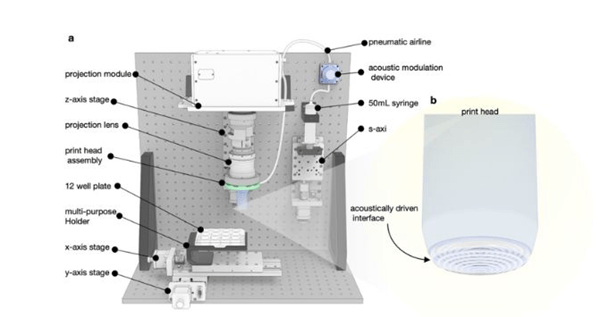

CAD model of the DIP printing system and its mechanical components.

What is special about this new process?

The dynamic interface printing process uses a pressurized tubular print head located above a reservoir containing liquid. The print head is designed to use carefully controlled acoustic vibrations to project light patterns onto a liquid surface, known as a meniscus. This step helps shape and stabilize the printing surface, thus promoting a regular and continuous accumulation of material. Through this process, overheating issues and printing errors can be avoided.DIP technology prints at speeds of up to 0.7mm per second, a significant improvement over previous methods.

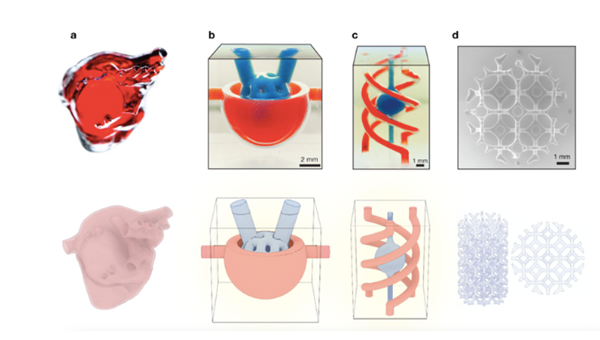

This process opens up vast prospects, particularly in the field of bioprinting, where precision and biocompatibility are crucial. In fact, this approach can accelerate the development of complex cellular structures. In trials, researchers demonstrated its effectiveness in increasing cell survival and reducing printing times, while eliminating physical handling and ensuring process sterility.

The image above uses the newThe part printed by DIP system, the picture below is its CAD model.

Applications of this technology range from the production of biological models to the manufacturing of living tissues. Callum, one of the lead authors of the study“Biologists see great potential in bioprinting, but until now its use has been limited to low-volume applications,” explains Callum Vidler. The DIP process can now overcome these limitations and improve speed, accuracy and consistency. Callum Vidler added: “This establishes an important link between laboratory research and clinical applications.

Australian team withThe collaboration of more than 60 researchers, including experts from Harvard Medical School and the Sloan Kettering Cancer Center, demonstrates the global interest in this technology. “The feedback has been overwhelmingly positive,” Mr Vidler said.

The future of dynamic interface printing

Dynamic interface printing technology marks the beginning of bioprinting andSignificant advances in 3D printing have revolutionized the way light is used to achieve high precision. The synergy between process speed, biocompatibility and precision could usher in a new era of 3D printing.

As its creator points out, this technology“Fills a gap in the field of bioprinting” and marks the beginning of a future that goes beyond the limits of current technology.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.