3D glass thermal bending was basically determined to use graphite molds, which adds another graphite processing technology to CNC. Due to the graphite material itself, not all CNCs can be processed. There are many issues to consider, such as equipment selection, jig design, tool selection, etc. It is reported that graphite molds account for about 20% of the materials. the rate of hot bending defects.

1. What “preparations” need to be made before CNC processing of graphite?

1. Select graphite processing equipment

(1) The suction intensity should be high

Graphite processing places very strict demands on the machines. The powder not only causes damage to the machine, but also causes some damage to people. Therefore, the recommendations for the dust collection intensity of the equipment are as follows:

1) The frequency converter controls the operation of the vacuum cleaner and reduces the source of vibration

2) The dust suction port is close to the treatment area and can be vacuumed quickly

3) The regular dust blowing design allows the graphite dust deposited in the corners to be blown and vacuumed without staying inside the machine.

4) The tool magazine door is equipped with an air blowing device to prevent graphite dust from entering the tool magazine and sticking to the tool handle, thereby affecting the accuracy of machining.

(2) The tightness of machine tools is very important

The sealing of the tool magazine, including the design of the Y axis, must be very strict. If the sealing of the machine tool is not done well and dust enters the equipment, it and some electronic components will basically not exceed 3 months. will gradually be damaged. It is recommended that the Y axis dust cover be integrated designed to improve the protection performance.

(3) Generally, solid rail oil is required

Graphite equipment generally uses solid guide oil. The reason graphite guide oil still drips is that the oil will precipitate over time, producing waste oil which will also slowly drip into the graphite or machine.

1) Once the rail oil flows on the graphite surface, it will destroy the material;

2) Use a dripping oil recovery device to absorb oil regularly and recycle waste oil.

2. Design the processing template

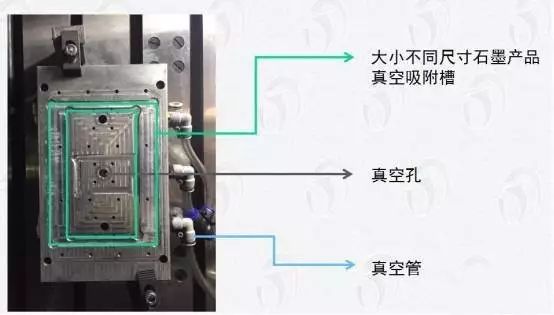

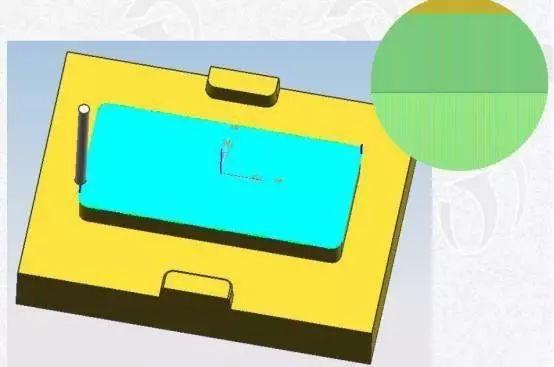

vacuum jig

The picture above is a vacuum device. A device can produce two or more products. Currently, many vacuum adsorption tables are used. A machine table can accommodate up to 3 to 4 large and small machines. Some graphite processing uses tools, but they are used to make mold electrodes; Vacuum adsorption tables are generally used to make graphite molds, which have stable processing dimensions and low deformation.

3. Choose the tool

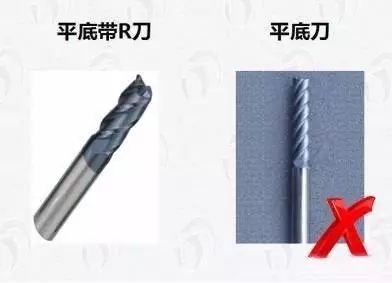

The difficulty of graphite processing also lies in the cutting tools. Cutting tools wear out very quickly in China only take 3-4 hours, and the best ones take 5 hours. Knives imported from abroad only take about 6-8 hours. When choosing a tool, try to choose a flat bottom R knife instead of a flat bottom knife (when roughing and finishing). Because the tip of the flat knife is sharp, the graphite will chip easily when cut. Graphite is relatively hard and brittle. If you cut it with something too sharp, it will fall apart easily. Therefore, when cutting, we now choose tools with a tip angle R (0.5R or 0.2R).

Ball knives are generally used for finishing. The biggest loss is the R knife, as shown below. The processing time for one set of molds is 2 hours, and the processing time for thin molds is 3 hours. At present, China is also working hard to study the materials and coatings of cutting tools, hoping that the processing time will be longer and the cost will be reduced.

4. Set parameters and select tools at different processing stages

1) Open it roughly

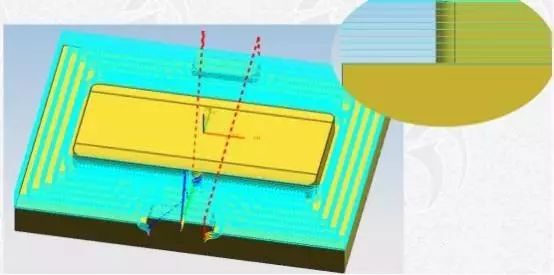

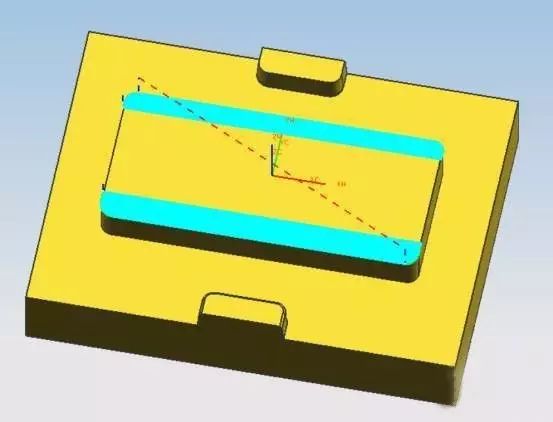

Raw Graphite Open Processing Path

The picture below is a simple graphite processing path, which is a roughing path. Next to it is the enlarged roughing cutting depth and processing amount of each tool.

Parameter Settings:

Cutting quantity: 2 ~ 3 mm

Processing speed: 3 ~ 4 m/min

Spindle speed: 10,000 ~ 12,000 rpm

Tool selection:

Coarse cutting knife: four blades, 10 ~ 12mm

(The diameter is too small: the speed is slow and the treatment is ineffective)

(The diameter is too large: the tool swing is significant, which affects the machining precision)

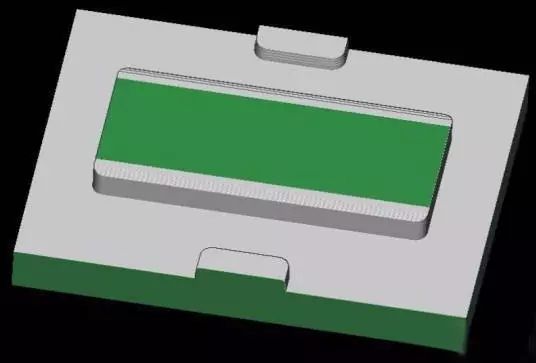

Bold renderings

2) medium coarse

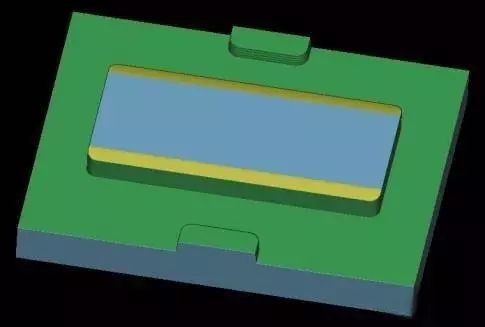

Medium Coarse Graphite Processing Path

As shown in the image above, the tool path is medium coarse. Typically we will use the R knife at medium-coarse between finishing. This will reduce the amount of finishing and there will be less wear on the finishing knife.

Parameter Settings:

Cutting quantity: 0.5 mm

Processing speed: 3 m/min

Spindle speed: 15,000 rpm

Tool selection:

Knife R: R3 (with curved surface, the curved surface is slightly larger, suitable for roughing the curved surface)

Medium thickness coatings

3) Refinement

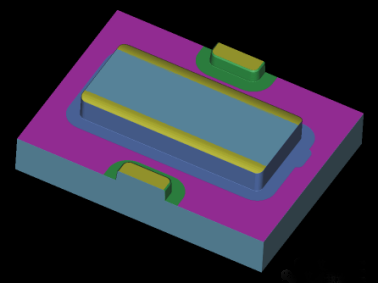

Refinement of graphite machining trajectories

The image above shows the finishing machining path. There are many paths to finish the climbing surface: 0°, 45°, 90°, including circular paths. Currently, the best cutting effect is 90°. Overall, it’s the best. Generally, the R knife is used for finishing and the effect is better. However, foreign machine tools use round nose tools, which require high precision of the machine tool. The cutting precision like Makino and Mikron is very high, and it will be very bright when cut with a round nose knife. Basically, she doesn’t need to be polite.

Parameter Settings:

Cutting quantity: 0.03 mm

Processing speed: 3 m/min

Spindle speed: 22,000 rpm

Tool selection:

Punch: R knife: R2 (small curved surface, high speed adjustable, small vibration, improved processing effect).

Concave die: round nose knife (flat bottom with R knife) (6R0.5 / 4R0.2)

(6&4 represents diameter, 0.5&0.2 represents R angle. The smaller the R angle, the smaller the processing range and the finer the processing, which can handle corner position processing in the concave mold.)

Refined renderings

2. What problems will you encounter during CNC processing of graphite and how to solve them?

1. Knife line problem

1) Tool problem: It is recommended to use high quality tools as much as possible. At present, most cutting tool materials and coating formulas are imported. The materials and coatings of domestic cutting tools are still under extensive research.

2) Post-processing: cooperate with the special post-processing program of the CNC system.

2. Dark Pattern Issue

Machine tools, cutting tools, etc. will affect accuracy and produce dark lines.

1) System problem: system parameters need to be adjusted, select “high-precision repair” mode, and cooperate with system-specific post-processing;

2) Tool feeding method: It is recommended that two axes move at the same time instead of three axes. 45° typically uses three axes moving at the same time. If all three axes move at the same time, the effect is not so good and it is easy to produce knife marks.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.