The “impossible triangle” is an economic concept, which means that a country cannot have free movement of capital, exchange rate stability and independence of monetary policy at the same time, and can only satisfy a maximum of two of them. Horizontal machining centers are mainly used to process large quantities of complex parts. First, mass production requires high efficiency and long-term stability of machine tools. Second, complexity implies higher precision requirements. Therefore, from the point of view of processing, horizontal machining must have three characteristics: high efficiency, high precision and good stability.

In the market, the horizontal machining center products of foreign-invested manufacturers are very mature, and can often balance processing efficiency, processing precision and product stability. This is not the case for domestic machine tools. Many domestic horizontal machining machines can achieve high precision and high speed, but high speed is often accompanied by an increase in failure rate, so the stability is low and if emphasis is placed on high precision and stability, it cannot get the same treatment; like machine tools financed by foreign funds. Efficiency, which will lead to increased processing costs, is a fatal gap for customers requiring mass production.

01

Béjia market

The localization rate situation is more serious

The horizontal machining center, as the name suggests, is a horizontal spindle machining center. Compared with vertical machining centers, horizontal machining centers occupy a large area, have complex structures, and have high manufacturing costs. However, they are easy to remove chips during processing and have high processing efficiency. Some large and complex parts are those on vertical machining centers. not suitable for treatment not suitable for treatment. Can be processed on the horizontal machine.

The horizontal machining center itself is equipment that requires high efficiency, and the prerequisite for high efficiency is precision and stability. In summary, product performance requirements are very strict. This means that it is more difficult to develop and manufacture horizontal machining centers, and companies naturally have to invest more time, capital and other costs. The reality is that, on the one hand, the downstream industry has not shown strong demand for horizontal machining centers in recent years; on the other hand, policies regarding industrial machines have not been too oriented towards horizontal machining centers; Therefore, the product line of horizontal machining centers generally does not receive much attention from enterprises.

In the past, five-axis machine tools have always been listed as one of the “blocked” products. In recent years, thanks to the support of national policies and the massive investment of a large number of domestic enterprises, the localization rate. has reached a high level, and there have also been developments such as A number of companies specializing in five-axis production include Code, Tuopu, Evermi and Jinke. Today, more and more companies focusing on five-axis R&D and production continue to emerge. So, what is the localization rate of horizontal machining centers?

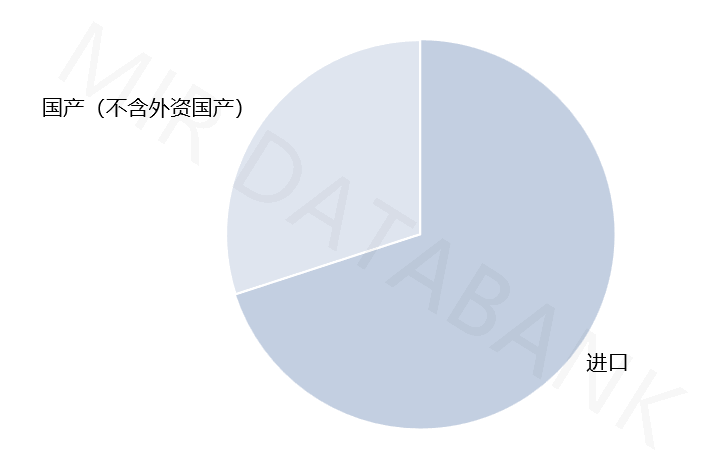

Localization rate of mid-to-high-end horizontal processing equipment in 2023 (in terms of value)

Data Source: China Horizontal Machining Center Market Research Report 2024

According to MIR statistics, the current localization rate of mid- and high-end horizontal machining centers in China is about 30%. In the TOP10 horizontal machining center enterprise list, only three domestic enterprises are on the list and they are ranked at the bottom of the list. Many manufacturers can produce horizontal machining centers, but few of them are good at this and have a large scale. Therefore, the current situation is that domestic manufacturers generally have a small market share, the performance advantages of their products are not outstanding, and the most well-known brands in the market are mainly Japanese, Korean brands. and European. National substitution still has a long way to go.

02

Wojia Market Development

Recovery after a slowdown

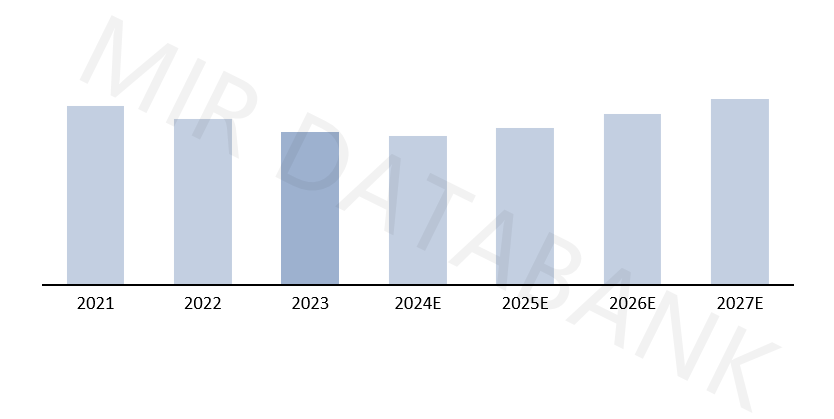

Evolution of horizontal E processing market size from 2021 to 2027 (amount: 100 million yuan)

Data Source: China Horizontal Machining Center Market Research Report 2024

Benefiting from the stable development of new energy automobile industry and construction machinery industry, the market size of horizontal transformation industry will reach its peak in 2021. Especially, new energy automobile parts enterprises will increase their equipment purchasing efforts in 2021, leading to a boom in sales of autonomous horizontal processing machines and FMS flexible lines in 2021.

Since 2022 and 2023, the horizontal machining center market size has continued to decline, mainly due to three factors. On the one hand, at the macro level, due to the slowdown in economic growth, lack of confidence in investment in the manufacturing industry and the more cautious attitude of enterprises, the overall demand for machine tools of the manufacturing industry shows a weak trend. On the other hand, from an industry perspective, the demand for horizontal machining centers for traditional automobiles has fallen to the freezing point; investment in new equipment for new energy vehicles has also gradually slowed down, and the large-scale purchase of new energy vehicle production lines has also slowed down. equipment gradually became a thing of the past; Engineering machine prices have been falling since 2022 and the demand for purchasing horizontal machining centers from OEMs and supporting suppliers has declined again and again. Finally, as land and labor costs increase in China, the relocation of manufacturing industries also affects the demand for domestic machine tools to a certain extent.

In the first half of 2024, the overall market did not experience the expected growth recovery and sales in various sectors remained sluggish. In the fierce market competition, more and more manufacturers begin to “raise prices”. Irrational competition is unsustainable and has also led to a decline in average selling prices. By mid-2024, some industries may experience a recovery trend. For example, the production and sales of new energy vehicles continue to increase for a long time, and the 3C market space is still large. electronics experienced strong restorative growth; aerospace has continued to grow steadily.

03

Competitive landscape

Foreign investment is the absolute mainstream, and domestic investment still has a long way to go.

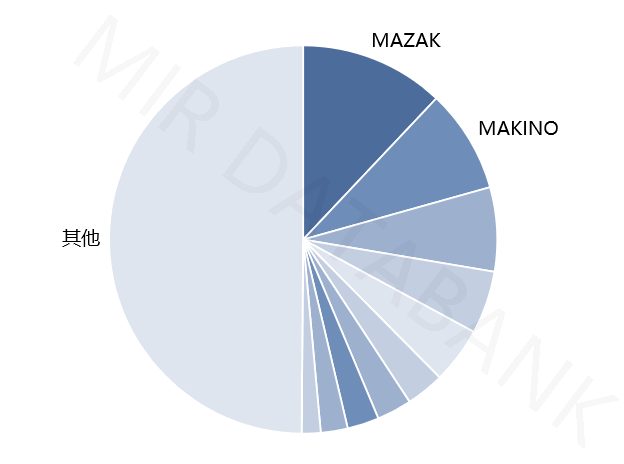

Wojia Competitive Landscape in 2023 (In Terms of Value)

Data Source: China Horizontal Machining Center Market Research Report 2024

There are many manufacturers of horizontal machining centers, which can be divided into four major tiers in terms of competition:

● The first tier consists of European manufacturers represented by GROB, SW and HELLER, which are characterized by high precision, high prices and relatively specific areas of application.

● The second tier consists of MAZAK, MAKINO and other Japanese and Korean manufacturers, which are characterized by good product performance, greater versatility and a wide application range.

● The third tier includes domestic well-known brands including Taiwan, such as Haitian Precision, Neway CNC, Rifa Precision Machinery, Ningjiang Machine Tool, Youjia Machine Tool, etc. There is a certain gap between the horizontal processing performance of these manufacturers and imported brands, but the prices are relatively low.

● The fourth tier is a small, unknown company in the country, which produces and manufactures at the lowest prices for horizontal processing, and mainly serves small start-up manufacturing companies.

The market size of horizontal machining centers is concentrated towards the top, with the two largest companies MAZAK and MAKINO accounting for more than 20% of the market share. Both are Japanese companies and their B&B products rank among the best in the Chinese market in terms of market share and popularity.

Among the ten largest companies in Wojia, there are only three domestic companies, namely Haitian Precision, Neway CNC and Rifa Precision Machinery. Other domestic manufacturers’ horizontal machining centers rarely exceed RMB 100 million and are generally small. Horizontal machining centers are typically produced and sold as a non-traditional supplemental product line of the company.

04

Applications downstream of the horizontal machining center and machined components

Automobiles and construction machinery are the main industries

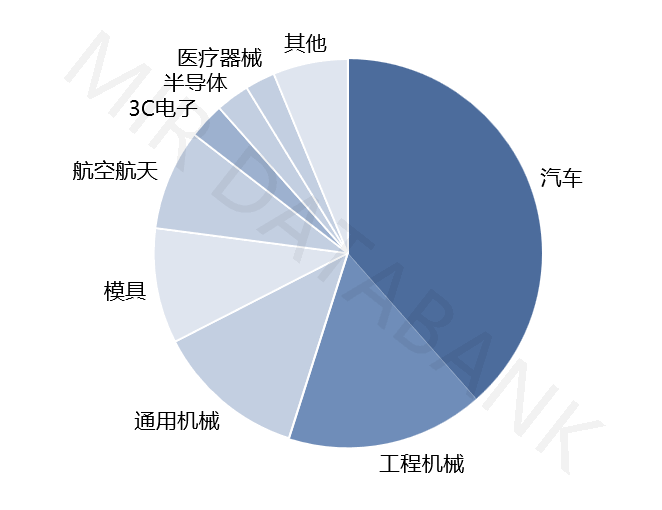

Wojia Downstream Industry Segmentation in 2023 (In Terms of Amount)

Data Source: China Horizontal Machining Center Market Research Report 2024

Automotive is B&J’s largest downstream industry. Although the shrinkage of the fuel vehicle market has had a certain impact on the demand for B&J, the rise of new energy vehicles has brought more application opportunities to B&J, but their processing difficulty is generally lower than that of B&J. fuel vehicles. Engine parts. In the past, the processing of essential automobile engine components, such as cylinder blocks and cylinder heads, was monopolized by foreign machine tools. Today, the core components of new energy vehicles and three electrical components bring new opportunities to domestic machine tools.

Engineering machines take second place. Hydraulic components and some structural parts are suitable for horizontal machining, and the demand for production lines is also large. In addition, the aerospace and semiconductor industries are developing rapidly and the demand for horizontal processing is increasing rapidly.

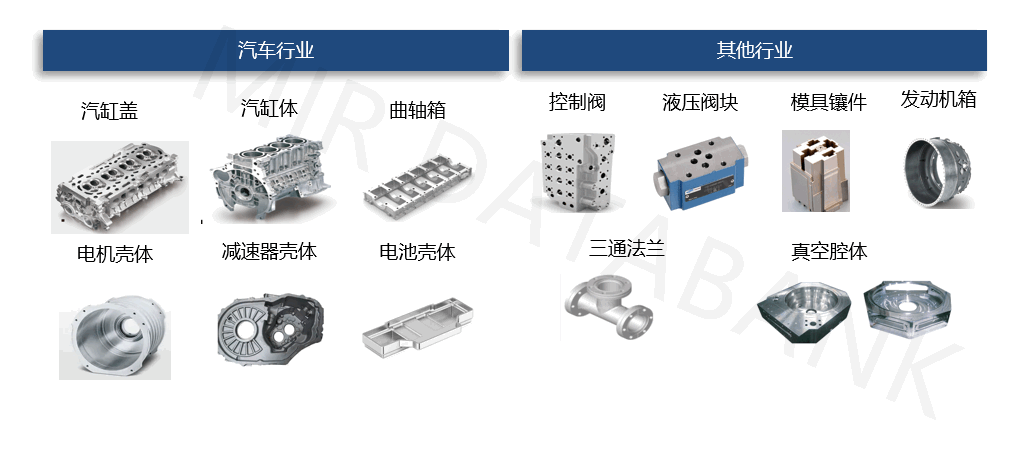

Horizontal Machining Parts

Photo: MIR Rui industrial finishing

Horizontal processing is most suitable for processing precision box parts, shell parts, disc parts and special-shaped parts, and is widely used in various industries. For example, cylinder blocks, cylinder heads, gearbox housings, etc. in the automotive industry, engine housings, gearbox housings, etc. in the new energy automobile industry, and hydraulic valve blocks in the engineering machinery industry. The most typical application of horizontal machining centers is to process the “three main parts” of automobiles: the cylinder block and cylinder head, the gearbox and the crankcase. At present, there is very little market demand for new production lines, and most of them are replacement, replacement and transformation needs.

At present, vertical three-axis and vertical five-axis machines are mainly used in the market, and the penetration rate of horizontal machines is not high. However, horizontal machining has significant advantages such as high efficiency processing and good chip removal effect, which prevent chip residue from affecting the processing quality. Besides the increasing demand for flexible production and processing, it has become increasingly popular. in the competition in the aviation market, machinery manufacturing, automobile parts and other markets, more and more favor. As acceptance and penetration increase, horizontal machining centers will play an increasingly important role in factories in the future.

05

National horizontal processing enterprise

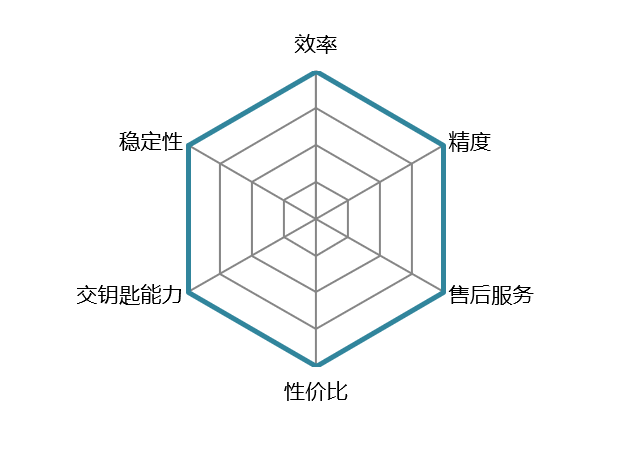

Break the “Impossible Triangle” and strive to become a “Hexagonal Warrior”

The above analysis shows that the horizontal processing products of domestic manufacturers are not very mature and their market share needs to be improved. Take the example of the famous Haitian manufacturer Seiko. Its sales in 2023 will represent less than half of those of the Japanese Mazak. Horizontal machining in Japan and Europe has developed rapidly. Through the accumulation of technologies and practical verification of long-term processing in the automobile industry and other industries, their products are more mature, whether in terms of processing efficiency, processing precision or stability of use. to none.

The development status of foreign machine tools tells us that precision, efficiency and stability have never been the “impossible triangle” for horizontal machining. What domestic machine tools need more is to focus on product quality and carry out targeted market-based product research and development. request. Design and production. For domestically funded enterprises, making good products is the most important and fundamental starting point.

In addition, as the demand for flexible manufacturing increases, the turnkey capabilities of horizontal processing manufacturers are also one of the goals of customer evaluation. Foreign-invested companies such as Mazak and GROB all have strong turnkey teams. Machine tool sales are inevitably accompanied by untimely and inadequate after-sales service will reduce customer favorability and affect subsequent purchases. High-quality after-sales service can not only promote sales, but also become one of the sources of profit.

In addition, domestic companies also need to control their costs more. Most foreign-invested manufacturers produce horizontal machining machines in China, reducing costs and sales prices, as well as the price advantage of domestic machine tools.

Through future development, I believe that domestic machine tool enterprises can not only break the “impossible triangle”, but also develop horizontal machining machines into “hexagonal warriors” integrating precision, efficiency, stability, turnkey capabilities , after-sales service and cost. -efficiency As with current domestic vertical machining centers, it is no longer necessary to use foreign products.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.