Does NX Work For 4/5 Axis Machines Introduction

NX is a versatile and powerful CAD/CAM software solution, widely regarded as a top choice in the manufacturing industry. One of the most frequently asked questions by professionals is whether NX can effectively handle the programming and machining needs of 4-axis and 5-axis CNC machines. The short answer is yes. NX not only supports these advanced machines but provides specialized tools and capabilities to maximize their potential.

What is NX Work?

NX, particularly its CAM (Computer-Aided Manufacturing) module, is specifically designed to meet the demands of multi-axis machining. This includes:

- Advanced Programming: NX CAM facilitates the creation of complex toolpaths tailored for 4-axis and 5-axis CNC machines.

- Collision Detection: Integrated collision detection ensures that operations run smoothly and without damage to tools or workpieces.

- Comprehensive Post-Processing: The software supports a wide range of CNC machines, generating precise machine-ready code.

These features make NX an industry leader for machining complex geometries that require multiple rotational axes.

Key Advantages of NX CAM

Efficient Toolpath Generation

NX CAM provides advanced algorithms that generate efficient and optimized toolpaths for 4-axis and 5-axis machining. This ensures minimal tool engagement, leading to:

- Improved surface finishes.

- Reduced tool wear.

- Shortened machining cycles.

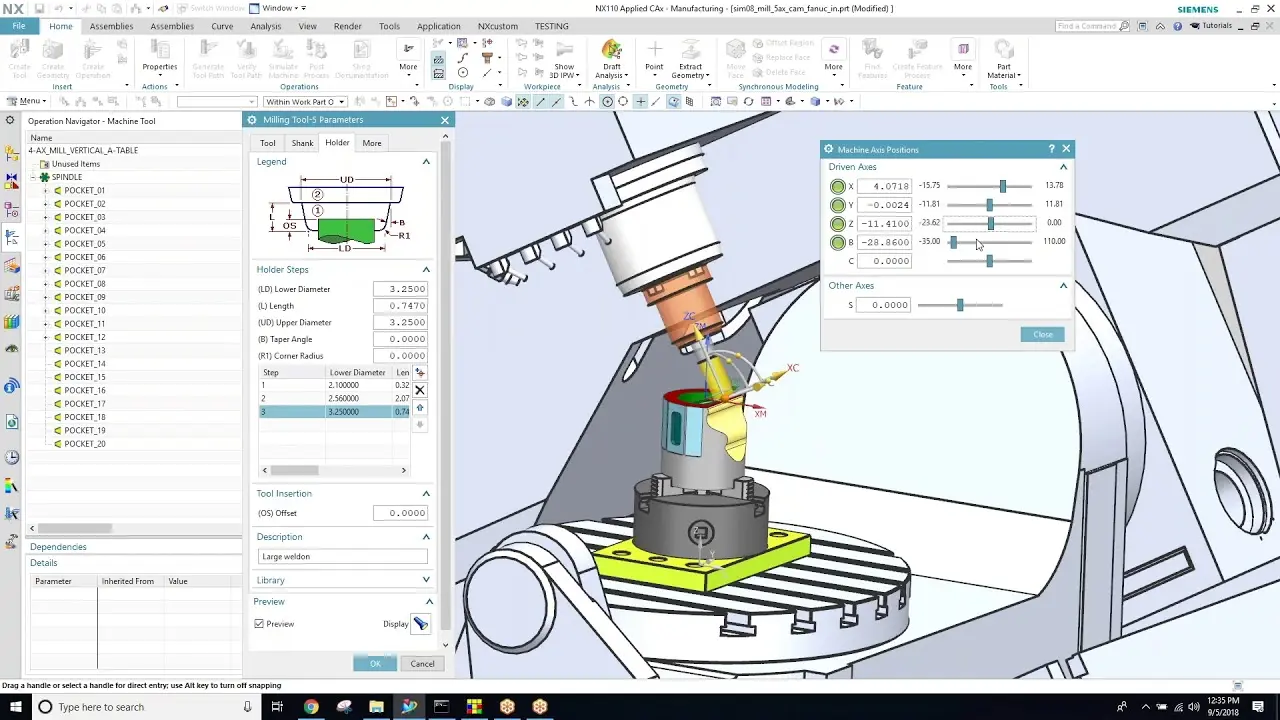

Simulation and Validation

The software offers robust simulation tools, allowing users to:

- Visualize machining operations in a virtual environment.

- Detect and resolve potential issues such as collisions or tool interferences.

- Validate programs to ensure machining accuracy.

High-Speed Machining (HSM)

NX incorporates high-speed machining strategies, including:

- Adaptive clearing for material removal.

- Feed rate optimization for smooth operations.

- Reduced machining time while maintaining high-quality finishes.

Integrated CAD/CAM Workflow

NX’s seamless integration of CAD and CAM allows users to:

- Design parts and setups within the same software.

- Quickly transition from design to manufacturing.

- Streamline workflows for enhanced productivity.

Features for 4-Axis and 5-Axis Machining

4-Axis Machining Capabilities

4-axis CNC machines add an additional rotary axis, often enabling:

- Engraving and slotting on cylindrical parts.

- Indexing for machining on multiple faces of a part.

- Enhanced productivity with fewer setups.

NX CAM excels in programming these operations, providing strategies for multi-face machining and synchronized motion.

5-Axis Machining Capabilities

With the addition of a second rotational axis, 5-axis CNC machines enable the production of highly complex parts. NX offers:

- Full Control of Tool Motion: Achieve precise cutting angles for intricate geometries.

- Automatic Deburring: Program deburring operations to ensure smooth edges and surfaces.

- Advanced Strategies: Execute contouring, swarf cutting, and variable-axis milling with ease.

Real-World Applications

Aerospace

The aerospace industry relies on 5-axis machining for components like turbine blades and airframes. NX enables:

- Accurate toolpaths for complex curves and surfaces.

- Simulation to ensure collision-free machining.

- High precision for critical parts.

Automotive

High-performance automotive components often require 4-axis or 5-axis machining. NX supports:

- The creation of tight-tolerance engine blocks and suspension components.

- High-speed machining for productivity.

- Superior surface finishes for functional and aesthetic parts.

Medical Devices

Medical device manufacturing demands precision and complexity, which are achievable with NX CAM’s capabilities:

- Creating intricate designs for implants and surgical tools.

- Simulating operations to prevent errors.

- Maintaining high standards of quality and consistency.

Beyond the Basics: NX’s Advanced Technologies

Adaptive Clearing

NX’s adaptive clearing algorithms optimize material removal, reducing cycle times and improving tool life.

Toolpath Optimization

From roughing to finishing, NX CAM enables users to optimize toolpaths for:

- Maximum efficiency.

- Minimal tool wear.

- High-quality results.

5-Axis Simulation and Virtual Machining

Virtual machining capabilities allow manufacturers to:

- Simulate operations with real-world machine models.

- Identify and resolve potential problems before machining.

- Save time and reduce material waste.

Understanding 4/5 Axis CNC Machines

What are 4-Axis Machines?

These machines extend traditional 3-axis capabilities with a rotary axis, typically used for operations like:

- Indexing parts to different orientations.

- Milling cylindrical or angled features.

What are 5-Axis Machines?

5-axis machines add another rotational axis, providing unparalleled flexibility. This is essential for:

- Creating complex aerospace and medical components.

- Machining freeform surfaces with precision.

Conclusion

NX is a comprehensive and robust solution for managing 4-axis and 5-axis machining operations. With its advanced programming capabilities, simulation tools, and support for high-speed machining, NX ensures precision, efficiency, and quality. Whether in aerospace, automotive, or medical industries, NX empowers manufacturers to tackle complex geometries and intricate designs with confidence.

Related reading: Does Savage Axis 2 6.5 Creedmoor For 4/5 Axis Machines?

Introduction

Savage Axis 2 6.5 Creedmoor is a very popular hunting rifle, which is widely used in hunting and shooting competitions for its accuracy and performance. The finishing of parts such as stocks, barrels, and bolts is very suitable for CNC machining technology, especially 4-axis and 5-axis CNC machines, which can play an important role in the manufacture and customization of firearms parts. CNC (Computer Numerical Control) machining is a high-precision manufacturing process that is usually used for mass production and the manufacture of precision parts. It plays an important role in modern firearms production, especially parts with complex shapes. 4-axis and 5-axis CNC machines can provide higher precision and flexibility, and are particularly suitable for the processing of complex firearms parts.

1. CNC Machining Requirements for Savage Axis 2 6.5 Creedmoor

Stock

The stock is an important part of the firearm, which is usually made of wood, plastic, alloy or composite materials. CNC machines, especially 5-axis machines, are very effective in processing gun stocks, especially when complex shapes need to be engraved or polished. Using 5-axis machines can achieve complex curved surface cutting and engraving of custom patterns, providing higher precision and aesthetics.

- Processing of wooden gun stocks: Wooden gun stocks usually require complex engraving processes. CNC machines can achieve precise curves and detailed engraving, avoiding errors in manual processing.

- Processing of composite gun stocks: For composite materials such as carbon fiber and fiberglass, 5-axis CNC processing can cut and shape more accurately, ensuring the sturdiness and stability of the gun stocks.

Barrel

The processing of the barrel is one of the most critical links in the entire firearms manufacturing process. Traditionally, the inner cavity processing of the barrel requires very high precision, especially in terms of caliber, rifling and surface finish. Modern CNC technology, especially 4-axis and 5-axis machine tools, can provide higher precision and more complex processing methods, which are suitable for the manufacture and finishing of gun barrels.

- Barrel shape processing: Using 5-axis CNC machine tools, manufacturers can complete the inner and outer shape processing of the barrel in one processing process, reduce the fixture switching and processing errors of the workpiece, and improve production efficiency.

- Bore processing: The processing requirements of the inner cavity of the barrel are very high, and it is usually precisely processed by the bore processing machine tool. 5-axis technology can achieve more complex bore processing, especially precise rifling processing.

Bolt

The bolt is usually a complex mechanical component that requires high strength and high precision. CNC machine tools, especially 4-axis and 5-axis machine tools, have obvious advantages in the processing of bolts. 5-axis CNC machine tools can process bolts at multiple angles to ensure the accuracy of their various contact surfaces, holes and threads.

- Multi-faceted processing of bolts: 5-axis machine tools can perform multiple processing surface operations at the same time, such as processing the locking groove and guide surface of the bolt, reducing manual intervention and improving precision.

- Complex geometry: The geometry of the bolt often involves complex grooves, holes and cuts. 5-axis CNC machines can handle these complex geometries without frequent fixture changes, ensuring the consistency and accuracy of the machining process.

2. Application and advantages of CNC machining in firearms manufacturing

High precision and consistency

CNC machining can provide much higher accuracy and consistency than traditional manual machining. Especially in the machining of firearms parts that require micron-level precision, 4-axis and 5-axis machines can accurately control the motion trajectory of each tool to ensure that each component meets strict tolerance requirements and avoid performance instability caused by manual errors.

Machining of complex geometries

In firearms manufacturing, many parts (such as bolts, stocks and barrels) have complex geometries, and traditional machining methods may not be able to efficiently and accurately machine these complex shapes. 4-axis and 5-axis CNC machines can process on multiple planes at the same time through their multi-axis motion capabilities, achieving more complex and sophisticated machining effects.

Improve production efficiency

CNC machine tools can automate the processing process, reduce errors caused by manual operation, and complete multi-faceted processing on the same machine tool, reducing the number of times the workpiece needs to be re-clamped. This highly automated production method can greatly improve production efficiency and shorten production cycles, especially in mass production.

Reduce manual operations and manual errors

The use of 4-axis and 5-axis CNC machining technology reduces a large number of manual operations in the production process, especially for the processing of complex parts, reducing quality problems caused by manual errors. In addition, the accuracy of CNC machine tools also makes the repeated production of parts more consistent.

3. The role of CNC technology in the customization of Savage Axis 2 6.5 Creedmoor

For hunters and shooting enthusiasts, customizing Savage Axis 2 6.5 Creedmoor can enhance the shooting experience. Through CNC technology, manufacturers can provide customized parts for firearms that better meet personal needs:

- Customized buttstock: CNC machining can customize the shape of the buttstock according to the user’s body shape and gripping habits, improving comfort and controllability.

- Personalized design: CNC technology not only supports the customization of functional parts, but also allows for design of appearance, such as engraving unique textures or logos.

- Optimizing barrel performance: CNC machining can provide more refined processing for barrels, optimize the rifling and inner cavity of the barrel, and improve accuracy and shooting stability.

Conclusion

Although the Savage Axis 2 6.5 Creedmoor itself is a shooting tool, its various parts (such as stocks, barrels, bolts, etc.) can indeed be manufactured through 4-axis and 5-axis CNC machining technology to improve accuracy and performance. 4-axis and 5-axis CNC technology can cope with the complex geometry and high precision requirements of firearms parts, providing firearms manufacturers with higher manufacturing capabilities and more precise processes. These technologies can not only improve the quality and consistency of firearms parts, but also play an important role in customized and personalized production.

For manufacturers of high-precision weapons such as the Savage Axis 2 6.5 Creedmoor, 4-axis and 5-axis CNC machining technology is undoubtedly a key tool to improve production efficiency, ensure quality and achieve innovative designs.