Unlocking Manufacturing Potential: The Science and Strategy Behind Cycloid Milling

Move beyond traditional machining bottlenecks. Cycloid milling is revolutionizing high-performance material removal, offering manufacturers unprecedented efficiency, tool longevity, and surface quality in demanding applications across aerospace, automotive, mold & die, and beyond. This in-depth exploration reveals why and how this cutting-edge strategy delivers unparalleled results.

Demystifying the Cycloid: Beyond Conventional Paths

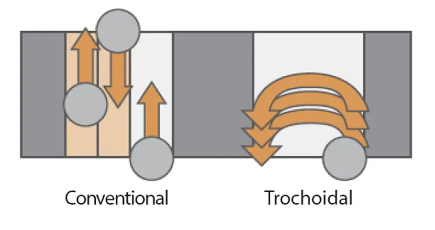

Forget linear or simple curved tool paths defining traditional machining. Cycloid milling harnesses a sophisticated, dynamic motion based on circular fragmentation. The cutting tool engages the workpiece in a series of continuously adapting circular arcs with varying diameters. The resulting trajectory? A precise, spiral-like "cycloidal" path. This complex movement fundamentally shifts how the tool interacts with the material. Instead of constant, grinding friction, cycloid milling creates intermittent engagement – the tool cuts, lifts, moves, and re-engages in a calculated, cyclic pattern.

The core mechanics rely on programming the tool’s center point to trace this specialized path around the desired groove or hole, which itself can be significantly larger than the physical diameter of the cutting tool. This capability is particularly transformative for cavity milling, slotting, pocketing, and dealing with complex internal geometries. Crucially, this methodology minimizes sustained friction and heat generation while maximizing chip evacuation efficiency.

The Engineered Edge: Why Cycloid Milling Outperforms

The shift from constant to intermittent contact unlocks a cascade of performance benefits:

- Radical Material Removal Rates (MRR): By optimizing the tool path for minimal engagement time per rotation, cycloid milling allows significantly higher cutting speeds without compromising tool integrity. Combined with the ability to utilize near-full axial depths of cut, this translates directly to faster machining cycles and soaring productivity.

- Revolutionary Tool Life Extension: Reducing friction equals less heat. Less heat means drastically reduced tool wear. The intermittent cutting action effectively gives the cutting edges time to cool between engagements, dramatically prolonging tool lifespan and significantly lowering per-part tooling costs, especially when machining tough alloys or composites.

- Superior Chip Evacuation: The inherent spiral motion acts like a conveyor belt for chips. This dynamic flushing effect prevents chip recutting, a primary cause of tool damage, poor surface finish, and heat buildup. Efficient chip evacuation is critical in deep pockets and challenging materials like aluminum or titanium.

- Exceptional Surface Finish Potential: Shorter contact duration per revolution and minimized vibration through optimized engagement significantly reduce chatter marks and irregular tool pressure. The result is consistently smoother surface finishes, often reducing or eliminating secondary finishing operations.

- Dramatically Reduced Cutting Forces: By engaging only a small radial portion of the tool edge per revolution while leveraging the full axial flute length, cycloid milling achieves its high MRR with surprisingly low radial cutting forces. This enables:

- Machining high-value parts on smaller, less rigid CNC machines previously unsuitable for aggressive cutting.

- Minimizing part distortion or vibration in thin-walled or delicate components.

- Pushing machine spindles harder without exceeding their torque or rigidity limits.

- Unmatched Adaptability & Tool Economy: The cycloid path inherently generates a working diameter larger than the tool’s physical diameter. Strategically, this means one cutter can machine features of varied sizes (e.g., different slot widths or pocket dimensions). This radically minimizes the need for extensive tooling inventories.

- Power Efficiency: Achieving aggressive MRR with lower forces means cycloid milling efficiently leverages the available spindle power on lower-horsepower machining centers, maximizing their output potential without requiring massive capital investment.

Material Mastery: Where Cycloid Milling Shines

Cycloid milling demonstrates remarkable versatility across a broad material spectrum, but strategic considerations enhance its effectiveness:

- Metals (Steel, Stainless Steel, Aluminum, Titanium): A primary domain, excelling by reducing forces and improving chip evacuation. Especially valuable for stainless steels prone to work hardening and gummy aluminum where chip control is critical.

- Thermosensitive & Difficult-to-Machine Alloys (Inconel, Waspaloy, Titanium Alloys): The minimized heat generation is paramount here. Cycloid milling protects part metallurgy by preventing thermal damage and drastically extends tool life in these notoriously abrasive and tough materials common in aerospace.

- Advanced Composites (CFRP, GFRP): Effectively manages the abrasive nature and delamination risk. The intermittent cut and gentle entry/exit reduce fiber tear-out and fraying, leading to cleaner cuts and improved surface integrity.

- Hardened Materials (Tool Steels (>45 HRC), Hard Coatings): The low-force approach allows practical machining of hardened steels and metals where traditional methods struggle, boosting efficiency in mold & die work.

- Non-Metallic Materials (Plastics, Exotic Polymers, Wood): Mitigates heat build-up (crucial for preventing melting or warping in thermoplastics) and significantly reduces tool abrasion, ensuring cleaner cuts and longer cutter life.

Material Optimization is Key: While broadly applicable, success hinges on tailoring cutting parameters (speeds, feeds, engagement angles), tool geometries (helix angles, rake angles), and coatings (AlTiN, DLC suitable for specific materials) to the specific workpiece material and desired operation.

Mastering Implementation: Proven Techniques for Success

Applying cycloid milling effectively demands more than just enabling the toolpath in CAM software. Leverage these critical best practices:

- Strategic Tool Selection:

- Full Solid Carbide: Non-negotiable for rigidity to handle dynamic forces. Integral shank designs minimize deflection.

- High-Performance Coatings: AlTiN, AlTiCrN, and DLC variants drastically enhance lubricity, heat resistance, and reduce adhesion for specific materials. PARK TiCo 4BC coating delivers high performance in steel and aluminum.

- Cutting Edge & Flute Count: Prioritize tools with robust edge preparation for toughness. Use multiple flutes (5-7+) to maximize metal removal per spindle revolution – the intermittent nature allows this without overheating. Variable Helix/Uneven Pitch designs are highly recommended to suppress harmonics and chatter.

- Parameter Optimization:

- Embrace High RPMs: Utilize your spindle’s full potential. Reduced contact time permits significantly higher surface speeds (SFM/m/min) than conventional approaches.

- Feed Rate Synergy: Match high RPM with aggressive feed rates (IPM/mm per min), ensuring optimal Chip Load Per Tooth (CPT/CLPT) based on tool/material. Required for efficient chip formation and energy distribution.

- Path Geometry: Optimize the "stepping diameter" of the cycloid loops (often 5-15% of tool diameter). Fine-tune overlap ratios to balance cycle time and tool life.

- Smart Toolpath Engineering:

- Leverage Advanced CAM: Utilize CAM systems offering robust cycloid/trochoidal strategies. Control entry/exit, overlap, stepover adaptation, and transition efficiency.

- Entry/Exit Strategies: Craft smooth, tangential engagement paths into the cycloid spiral to reduce shock loading.

- Prioritize Chip Evacuation:

- Program Strategically: Ensure toolpaths facilitate chip movement out of the cut zone. Avoid trapping chips.

- High-Pressure Coolant (HPC): Essential for deep pockets and challenging materials. Direct high-pressure streams precisely at the cutting edge for cooling and chip evacuation.

- Air Blast/Mist: Effective alternatives for materials incompatiblc with flood coolant (e.g., some composites).

- Maximize Rigidity:

- Secure Workholding: Ensure the workpiece is clamped rock-solid to resist the machining forces.

- Minimize Tool Overhang: Use the shortest possible tool length extension from the holder.

- Premium Tool Holders: Utilize Hydraulic, Shrink Fit, or HIGH-PRESSURE Collet holders for supreme clamping force and damping – heat shrink toolholders such as thermogrip is also a premium cutting tool clamping solution.

- Stable Fixturing: Ensure machine/workpiece vibrations are damped effectively. Damping toolholders can assist.

The Future is Cycloidal

Cycloid milling transcends being a mere toolpath option; it’s a holistic strategy for high-efficiency machining. By intelligently managing forces, friction, heat, and chips, it unlocks new levels of productivity, cost-efficiency, and capability, particularly on existing and less powerful CNC machine tools. As CAM software continues to evolve and machine tool capabilities increase, the adoption and sophistication of cycloid milling will only accelerate. Implementing its principles today positions manufacturers at the leading edge of competitive machining performance.

Key Visual Concepts for Layout:

- Schematic Animation: Illustration showing tool center path tracing a cycloid spiral vs. conventional linear slotting tool path (Top-Down View).

- Thermal Imaging Comparison: Thermal map overlays showing heat concentration on a tool using conventional path vs. minimal heat zones with cycloid path (Side View).

- Material Compatibility Matrix: Visual chart depicting material groups (Aluminum, Steel, Titanium, Composites, Plastics) with icons indicating Cycloid Suitability (High/Medium) and key tool/parameter recommendations.

- Tool Anatomy Highlight: Image labeling a specialized end mill showing features critical for Cycloid Milling: Solid Carbide Body, Robust Cutting Edges, Variable Helix/Uneven Pitch, Specific Coating.

- Chip Evacuation Flow: Diagram showing chips efficiently propelled along the flute gullets by the spiral path and coolant streams, away from the cutter/workpiece contact zone.