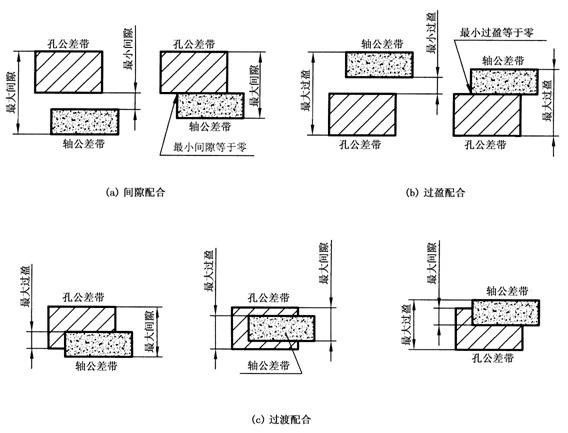

Interference fit, transition fit, and clearance fit are the three basic fitting relationships in mechanical design. When designing products, many people only consider interference fit if it is tighter, undercut fit if it is looser, and transition fit if it is neither tight nor loose . But is it enough? Of course not. There are many issues to consider behind these pairing relationships. In particular, adjustments with interference are most likely to cause problems. Today I’m going to give you an example of precautions for using interference adjustments.

Issues related to tight fit that should be noted:

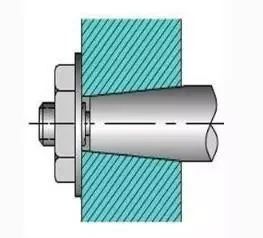

1. When the hole of the shaft is an interference fit, it must have a guiding function, that is, it must have a chamfer (the axis of the hole must have a certain chamfer, this that is to say that the entrance of the two corresponding parts must have a chamfer or conical surface playing a guiding role).

2. There should be a clear positioning mechanism between the interference fit parts (shoulders, bosses, etc. should be designed to ensure the interference fit depth of the product).

3. Avoid pressing two mating surfaces at the same time (two interference mating surfaces are pressed at the same time or almost at the same time, the assembly is very difficult, and the other mating surface must be designed such that the other mating surface can be pressed one by one).

4. When the tapered surfaces are mated, there should be no positioning structure (if the end faces are positioned, there may be a gap between the two tapered surfaces and the mating relationship will be lost).

5. When installing an interference fit in a blind hole, you should consider evacuating air. If a closed space forms inside the hole, it will be difficult to install. When shrinking, a vacuum will form inside, making the shrinkage uniform. more difficult. In order to avoid forming a closed space, small interior holes or grooves should be provided for ventilation (this will also facilitate ejection of the mold).

6. It is difficult to embed and remove a deep interference fit on the same size shaft. The length with interference must be limited to the minimum size necessary, leaving a slight gap in other parts to facilitate embedding (additionally if machining is carried out). the axis is long, only the corresponding parts are made to meet the requirements precisely, and the other parts are made larger or smaller with lower precision depending on the structure. In this way, the treatment is convenient and the cost is easy to control).

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.