The so-called deep hole is a (non-standard) hole processing method in which the ratio of the hole diameter exceeds 7 times the diameter. Deep holes are characterized by a depth-to-diameter ratio at least as high as 7:1. It is suitable for creating holes of required depth in different sizes. CNC machining materials range from aluminum, steel, titanium alloy, cast iron and other materials, and its application areas are relatively wide.

Deep hole drilling is a technique widely used in industry, but its origins were the need to drill high-precision straight barrels with depth-to-diameter ratios of up to 100:1.

Later, the technology continued to advance and expand to other applications, including the manufacturing of automotive parts (such as camshafts, crankshafts, fuel rails, and fuel injector bodies). ), low holes in injection molding, aerospace parts (such as landing gear), petroleum and various parts for the natural gas sector, general engineering components such as hydraulic cylinders, etc.

1. Types of deep drilling

1. Gun drilling process

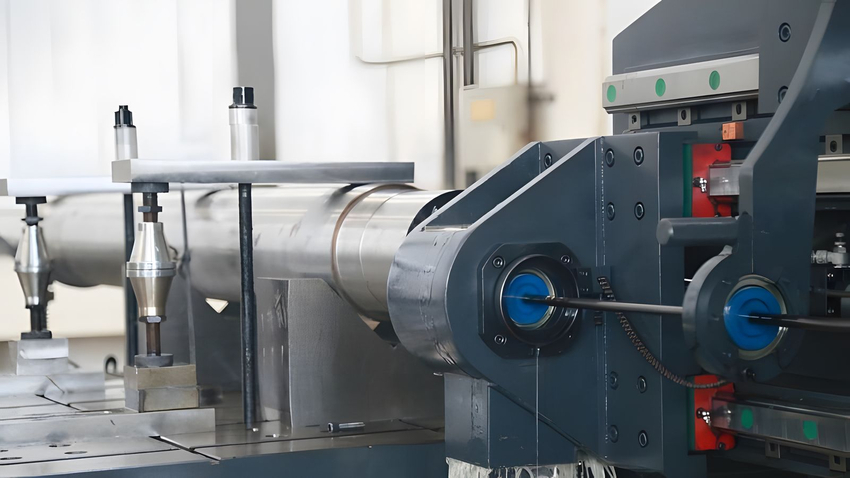

This deep hole drilling method uses a machine with a fine cutting tool to drill holes in the workpiece that are more precise and straighter. The introduction of barrel drills revolutionized the drilling industry as they were more precise than traditional drill bits.

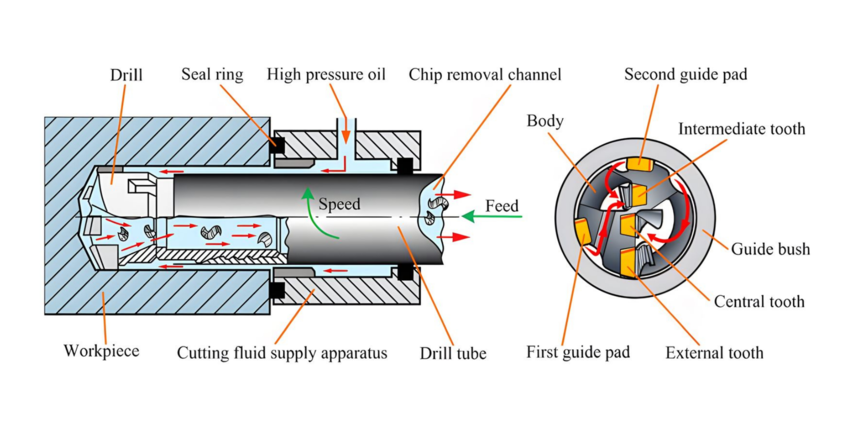

A barrel drill consists of a straight fluted cutting edge and a single internal coolant hole. As a result, pressurized coolant can be supplied through the internal bore while chips are removed via a single flute gun bit located in the shank. Therefore, material removal occurs simultaneously with drilling.

However, it may be possible to perform deep hole operations using a standard CNC barrel drill. Depending on the hole depth/diameter ratio, special tools can be used to achieve greater precision. Specialized deep hole drilling systems can achieve larger diameters, approximately 400:1.

2. BTA jet suction drill

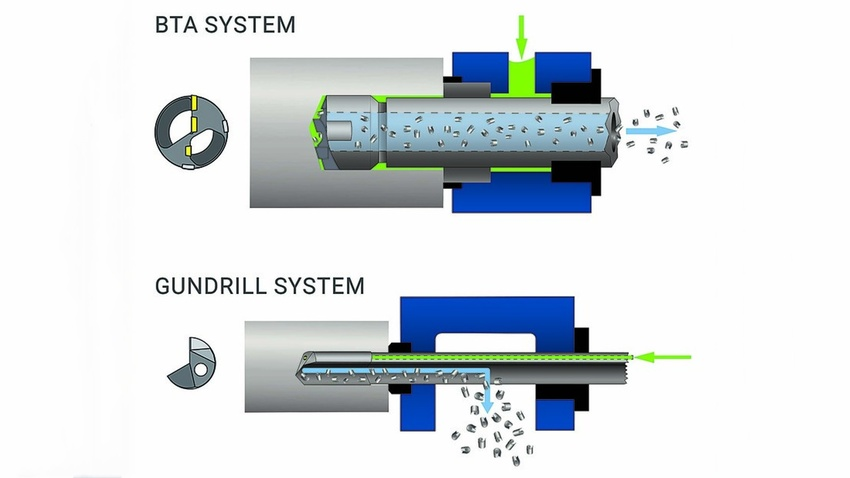

BTA drilling was introduced in the 1940s. The process involves inserting a special hollow tool into the hole, pushing pressurized coolant into the hole outside the drilling tool during the operation. It then expels the chips through the drill hole.

Additionally, the BTA tool or one-pipe system consists of a hollow drill tube attached to an indexable threaded bit, the exact size depends on the diameter and depth of the hole to be drilled. BTA tools are available in diameters ranging from 20 to 200 mm and depths up to approximately 400 mm.

Jet drills or twin-tube systems are commonly used on machining centers and conventional machine tools. It offers a drilling depth of approximately 100 x D. Although it is a variation of the BTA drilling system, it does not have seals to prevent cutting fluid from leaking onto the workpiece. machine. This drilling technique is therefore suitable for angled holes or discontinuous components.

In addition, the metalworking fluid must be transported through the annular space between the inner tube and the drill pipe. The fluid then flows down the sides of the bit and through the bit to cool and lubricate the bit. The cutting fluid pushes the chips through the internal cavity of the inner drill pipe for efficient removal. It is best to introduce a little liquid into the thinner tubular ring nozzle.

3. Extended twist drill

An extended twist drill is a cutting tool specifically designed for machining deep or difficult-to-reach holes. Compared with standard twist drills, its drill body is significantly longer, generally between 5 and 30 times the drill diameter, and is suitable for processing deep holes or hard-to-reach places. High-performance materials are generally used, such as high-speed steel, cobalt-containing high-speed steel, etc. Some extended twist drills also use coating technology to improve wear resistance and service life.

2. Main advantages of deep drilling

1. Precision and accuracy

Because deep hole drilling operations are automated, accurate hole depth/diameter ratios can be obtained. Deep drilling is therefore ideal for obtaining holes with precise dimensions meeting the requirements of industries such as aeronautics and defense.

2. Improve surface finish

The deep hole drilling process provides a better surface finish with less effort than the traditional method of using a twist drill bit. Deep drilling requires the use of specialized tools and setups to achieve high-pressure coolant flow and efficient chip evacuation, ensuring superior hole surface quality. As a result, this superior surface finish reduces friction and wear, ensuring durability and smooth operation of moving parts.

3. The importance of deep drilling in modern industry

1.Aerospace and defense

Deep hole drilling technology provides the tight tolerances and high precision required for machining aerospace components such as landing gear and turbine blades. The deep drilling process produces holes with precise tolerances to ensure optimal performance and low weight of these parts.

Meanwhile, the defense industry is another major area where deep hole drilling is widely adopted. Industry manufacturers use this drilling strategy to drill precise holes in gun barrels with ideal surface finishes.

2.Automotive applications

Automotive engineers and product designers rely on deep hole drilling to achieve optimal tolerances when machining automotive components. For example, fuel injectors in automobile engines require small, very precise holes to efficiently inject fuel into the combustion chamber. Additionally, the crankshaft and cylinder block require precise and deep holes to operate efficiently.

Additionally, deep hole drilling is essential for machining hydraulic cylinders for construction vehicles and other industrial applications. These hydraulic cylinders are essential for bulldozers, forklifts, excavators and much more. Deep hole drilling is ideal for drilling holes with the required precision to ensure smooth movement.

3. Oil and gas exploration

Deep drilling technology brings many benefits to the oil and gas industry as it makes it easier to drill holes for oil and gas extraction. The process achieves extremely high depth-to-diameter ratios on long parts without compromising wall thickness or roundness accuracy. Deep hole drilling is ideal for drilling holes with depth-to-diameter ratios up to 20:1.

4. Key points and precautions for its treatment

1. Choose the right type of drill bit

Select the appropriate deep hole drill bit type and size based on the hole diameter, depth and workpiece material.

2. Set the cutting parameters reasonably

Adjust the appropriate cutting speed, feed rate and cutting depth according to the processing conditions to ensure processing accuracy and surface quality.

3. Use an efficient cooling and chip removal system

Ensure cooling and lubrication of the cutting area, remove chips in time, and avoid chip clogging and tool damage.

4. Regular inspection and maintenance

Check the drill bits for wear regularly and replace or grind them in time to maintain good cutting performance and processing quality.

5. Tighten and stabilize the workpiece

Ensure the stability of the workpiece during processing and prevent vibration and displacement from affecting processing accuracy.

Deep hole drilling is a versatile process suitable for a variety of applications that have stringent requirements and unique challenges in machining rigid materials to tight tolerances. Knowing everything about this process will help us to effectively use its advantages to obtain high-quality products.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.