Mastering Milling Cutter Flute Design: Engineering Precision Through Chip Control

Milling operations live or die by chip evacuation. When metal meets machining forces, the pathways designed into your cutting tool spell the difference between flawless production and catastrophic failure. As materials grow more sophisticated and tolerances tighten, understanding milling flute geometries becomes non-negotiable for manufacturers. Let’s dissect the physics and application logic behind these high-precision channels.

The Fluid Mechanics of Milling: Why Groove Geometry is Mission Critical

Flutes form the helical channels spiraling around a milling cutter that serve as escape passages for ejected chips. Every groove must simultaneously optimize:

- Chip evacuation efficiency (preventing re-cutting and packing)

- Structural integrity (resisting vibration and deflection)

- Heat dissipation (transferring thermal load away from cutting edges)

- Surface interaction (minimizing friction while maximizing finish quality)

When these variables align, you achieve the elusive combination of high material removal rates and exceptional surface finishes.

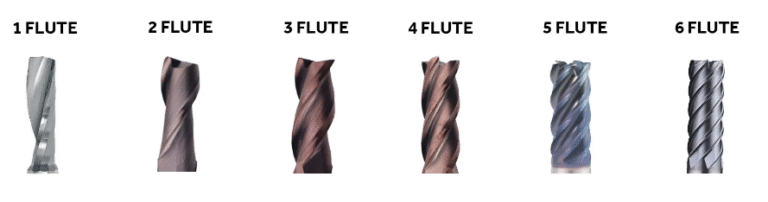

Number of Flutes: Strategic Selection Guide

Each flute count represents a compromise between productivity, rigidity, and application specialty:

◼️ Single-Flute Cutters: The Chip Flow Specialists

Application: High-efficiency soft material removal (aluminum alloys, plastics, wood composites)

Physics Advantage: Massive flute volume (45-50% more than 2-flute) allows uninterrupted chip flow without jamming. Low cutting pressure enables aggressive tool paths without deflection.

Use Case: Slotting 3x deeper than cutter diameter in aluminum at full width-of-cut. Exceptionally stable in thin-wall and vibration-prone setups.

◼️ Two-Flute Cutters: The Universal Workhorses

Application: Broad-spectrum capability (steel, SS, aluminum, engineering plastics)

Physics Advantage: Balanced combination of chip clearance and cutter body strength through alternating cutting forces. 100% stepover capability for contouring.

Use Case: Pocketing operations where radial chip ejection dominates. Ideal for CAM programmers needing one tool for roughing/finishing.

◼️ Three-Flute Cutters: The Finish Masters

Application: Aerospace composites, brass, copper, fine-finishing applications

Physics Advantage: Tri-lobed symmetry shifts harmonic frequencies outside excitation range to eliminate chatter marks. Allows 1.5x feed rates over 2-flute designs.

Use Case: Mirror-finish profiling (Ra < 0.8 μm) and dry machining applications through superior heat distribution.

◼️ Four-Flute Cutters: The Metal Removal Powerhouses

Application: High-efficiency steel milling, stainless steel roughing

Physics Advantage: 360-degree cutting support minimizes runout. Increased edge density enables faster feed rates without increasing teeth engagement time.

Use Case: Dynamic milling of tool steel up to 68 HRc. Optimized for high-temperature superalloys.

◼️ Five and Six-Flute Cutters: The Micromachining Innovators

Application: High-speed finishing (>20k RPM), small-part medical components

Physics Advantage: Micro-chipping risk decreases exponentially with distributed cutting load. Enhanced stepover stability maintains surface accuracy down to 0.01mm tolerances.

Use Case: 3D contouring of titanium implants; precision seal grooves where insert cutters fail. Sustained high MRR at depth ratios >5:1.

Groove Engineering: Beyond Simple Channels

Modern flute design transcends basic helical channels – see the principles behind breakthrough geometries:

| Design Type | Physics Principle | Performance Impact | Industry Use Case |

|---|---|---|---|

| Multi-Spiral | Fractured chip flow through alternating shear planes | Prevents birdnesting in deep cavities | Automotive cylinder head cavities |

| Variable Helix | Non-synchronized vibration phase cancellation | 52% vibration reduction over standard flutes | Aerospace thin-rib components |

| Polychoke™ (Patent-Pending) | Progressive flute narrowing control chip compression | Compacts chips while preventing welding | Stainless steel and Inconel slotting |

| True Trochoidal | Matched curvature to toolpath kinematics | Eliminates dwell marks in tight corners | Mold & die electrodes |

Cutting-Edge Hybrid Approaches

Adaptive Heliculoid Pattern

Recent R&D breakthroughs demonstrate how overlapping variable flute paths significantly reduce harmonic amplification. Patent USD934,703B2 documents helical offsets that:

- Create asymmetrical resonance patterns that naturally damp vibration

- Provide passive chip segmentation that breaks 304 stainless chips at source

- Allow 800 SFM cutting in titanium via controlled shear localization

Material-Specific Fluting Rules

Non-Ferrous Machining (Al/Cu):

- Choose low flute counts (1-2) with steep 45° helixes

- Apply PVD diamond coatings to nano-polished flutes

- Avoid straight grooves; seek chip-curling geometries

Hardened Steel (45-60 HRc):

- 4-6 flutes with reduced flute cross-sections

- Hybrid helix angles (35-42°) below centerline

- Micro-polished flute walls with zirconium reinforcement

Exotics (Ti/Inconel):

- Uneven spacing with cycloidal flute connections

- Parabolic gullet geometry to shorten chip contact

- Cryogenically treated to -200°C for stress relief

The Precision Selection Framework

Shape your cutter selection with this methodology:

Material Factor: Determine maximum chip thickness (hₘₐₓ) using:

hₘₐₓ = fₜ × sin(κᵣ) × √(DOC/aₑ)Chip Space Validation: Calculate minimum flute volume (Vₙ):

Vₙ > Q × CF / (N × f₂)

Where Q = MRR, CF = compression factor, N = rpm, f₂ = safety margin- Harmonic Testing: Use stability lobe diagrams to identify:

- Optimal spindle speeds for max material removal

- Resonance-free radial engagement limits

Future Horizons: Smart Flute Technologies

Embedded sensor-enabled cutters now enter prototype testing:

- Grinding resistance tracks (22μm wide) measure chip-load friction

- Micro-turbines in flute tips generate power to maintain active cooling flow

- Piezoelectric "choke valves" physically reshape flutes during engagement

These breakthroughs promise real-time digital process control that will transform tool management.

The Last Chip Falls Where Calculated

Flute design merges complex physics with practical application knowledge. The operator who understands helix harmonics, thermal pathways, and metallurgical interactions transforms machine tools into precision instruments. Your next breakthrough part won’t be created with guesswork – it’s engineered through arythmetic of flutes. Let this technical foundation guide your micro-to-macro machining strategy and redefine your capability thresholds.