Text/Wang Rong Shaanxi Hongyuan Aviation Forging Co., Ltd.

“Made in China 2025”, released by the State Council, highlights that “the manufacturing industry is the main body of the national economy, the foundation of a country, a tool for rejuvenating a country and the foundation of a strong country. The outline of the blueprint for manufacturing development highlights the goal of making China a manufacturing powerhouse by 2025. The aviation industry plays a central role in the country’s manufacturing industry. In particular, the aviation forging industry has always provided steel and iron frames for aviation equipment. the current development status of the industry is not in line with “Made in China 2025”. The requirements outlined in the plan vary widely. This article starts from the current status and existing problems of the aeronautical forging industry, and discusses the future intelligent manufacturing model of the aeronautical forging industry.

Current state of the aircraft forging industry

At present, manufacturers providing forging services to China’s aviation industry mainly include Shaanxi Hongyuan, Guizhou Anda, Wuxi Zhuoyue, Wuxi Hangya, Deyang Erzhong, Hangyu, Parker, Triangle Defense and other units, individual steel mills and leading engine research institutes. The institute also provides scientific research services in blacksmithing. Different from the assembly line, large-scale and mass production model of the traditional civil forging industry, the aviation forging industry has the characteristics of small batches, multiple varieties and high requirements. twenty-one Before the national military-civilian integration development strategy was proposed at the beginning of the century, aviation forging enterprises were representatives of China’s traditional military and heavy industries. The production management model of most companies was basically a broad, discrete management model. Industrial innovation was generally insufficient and energy use poor. Insufficient level of computerization, poor quality and efficiency. Specific to forging equipment, production technology, production line layout, personnel capabilities, etc., there are still generally “rough, scattered, chaotic and poor” situations. With the development of the modern aviation industry, this model can no longer adapt. Aeronautical forging products. Consistency control, quality stability and development requirements for intelligent manufacturing in the production process.

Main equipment

The aeronautical forging industry (of which AVIC Heavy Machinery is the leader) is an asset-heavy industry. Its main forging equipment includes hydraulic die forging presses, precision forging machines, rapid forging machines, electro-hydraulic hammers, counter hammers, pneumatic hammers, ring rolling mills, etc. The size of equipment tonnage is directly related to the size of the company’s production capacity. Except for the 800MN hydraulic press which was reinstalled in recent years and the 200MN hydraulic press newly installed by Shaanxi Hongyuan, the automation and efficient utilization rate of most other manufacturers’ equipment are still relatively weak, and they are fundamentally unable to meet the requirements of intelligent development.

Investigating the reason, the author believes that the aircraft forging industry requires large investments at the beginning, is slow to produce results, and has high technical obstacles. Therefore, the industry has always been controlled by a few specialized state-owned companies. businesses. In the national development strategy of “military-civilian integration” Before it was proposed, private companies were less involved.

Due to the influence of the planned economy, the competitiveness of enterprises in the sector is low and the updating of professional equipment of enterprises is slow, which ultimately becomes one of the important factors hindering the development of the industry. ‘industry. For example, Shaanxi Hongyuan still uses forging equipment such as counter hammers, pneumatic hammers and hydraulic presses that were installed when the factory was built in the 1960s. However, with the continuous improvement of user requirements in recent years, due to insufficient accuracy. equipment, the impact of energy control is difficult, and the quality of products is unstable and cannot meet the latest technical requirements of new combat aircraft. After several years of statistical analysis, it was found that customer complaints due to problems with forging surface quality and processing accuracy are also increasing year by year. Under the requirements of the development of refined processing of aerospace parts, this contradiction will become more and more obvious and intense. . If we cannot plan the changes in advance, we will lose our competitiveness in the field of aviation forgings in the future.

Aspects related to the production chain

In addition to the basic forging process, the aviation forging industry also needs to be equipped with the corresponding basic production line units such as forging heating, surface heat treatment, mold making, mechanical processing, physical and chemical testing and quality assurance. However, in the actual production process, due to the lack of effective control capabilities, the coordination efficiency between production units has always been relatively low.

For example, when a general aviation forging company configures multiple heating furnaces so that the main forging equipment heats at the same time, the heating operator essentially manually estimates the possible production rate of the main equipment, then adjusts the heating rate and heat preservation. of the time of the different heating ovens. However, in the production process itself, there is often wasted energy, materials, etc. due to artificial calculations and low control precision, and even worse, it may lead to poor product consistency.

Another example is that in the forging process itself, monitoring key parameters (forging temperature, deformation size, etc.) also brings problems such as time-consuming, high labor, high human resource costs and weak control capabilities. At present, major engine factories such as Chengdu Aircraft and XAC have to divest a large number of forging businesses due to business integration. This created the conditions for AVIC Heavy Machinery companies to become concentrated forging centers. production units are produced. This can significantly improve the input-output ratio, ensure product quality, and provide a guarantee to quickly improve the company’s competitive advantage in the future.

Management

To become a modern company in today’s manufacturing industry, the prerequisite is that it has a modern management model. However, among the existing aviation forging enterprises, there are common situations such as low business management efficiency, poor information management level and low coverage rate. Production management data processing in most companies is still manual or semi-manual, lacking the basic data environment required in modern business management, and the standardization, digitalization and standardization of management information within the company is far from sufficient. As a parent company, AVIC Heavy Machinery wishes to collect or view relevant information from its subsidiaries in real time. Currently, the conditions are not met or it requires a lot of manpower and material resources. This is inconsistent with the efficiency and effectiveness required by. modern business management.

Ideas for Intelligent Improvement of the Aeronautical Forging Industry

The integration of “two informatizations” is the future development direction proposed by the country. The application of 5G technology and the expansion of IoT technology provide support and foundation for future intelligent manufacturing. Intelligent manufacturing requires that during the production process, intelligent equipment is organically linked through effective communication technology and combined with the forging industry to achieve scientific product process design, automated production processes, Real-time on-site monitoring and intelligent analysis and improvement. Through data collection in the production process, various data are processed and analyzed by the software system to help business managers achieve optimal production plans. In recent years, the most developed enterprises in the forging industry are large auto parts enterprises represented by the production and processing of forgings for civil automobiles (such as Shaanxi Automobile Heavy Truck due to the characteristics of large batches of their products). , the degree of automation of forging and machining production lines reaching more than 90%, the production process has been basically achieved without manual intervention, automated production and automated testing, which sets an effective benchmark for the industry aeronautical forging.

To realize intelligent manufacturing, aeronautical forging enterprises must first have an effective “central nervous system”, that is, the enterprise must adopt a corresponding information management system (AVIC Heavy Machinery has developed an information system and initially has such a model), and gradually transform the original Transform the traditional process-based, extensive and manual management model. In the links of receiving orders (input), decomposition of the production plan, management of the production schedule (processing), delivery of stocks (output), processing of after-sales information (feedback ), etc., the information processing method of process control is transformed into the use of computer information systems for all enterprises. Resources are integrated, integrated and managed, that is, enterprise resource planning (ERP system) is used to manage logistics, information flow and value flow in the process of business management. As a forging enterprise, the main process of enterprise management includes three main modules: production process control (overall production plan, operation plan, auxiliary production plan, etc.), management materials (raw material procurement, auxiliary material procurement, inventory management, etc.) and financial management (accounting Accounting, financial analysis, financial planning, etc.). The intelligent management model uses the enterprise resource management system to integrate production management, quality management, laboratory systems, process management systems, energy management systems, basic standard databases, etc. in the forging production process to realize overall resource management and allocation. of the blacksmithing business. Smooth the “nerve circuits” in the company’s production management process.

Considering the problems of many varieties, small batches and small quantities, the intelligent transformation of forging production and auxiliary equipment can most directly improve the accumulation of actual product data in the forging production process, which facilitates subsequent analysis and improvement of product quality; for forging auxiliary equipment Intelligent transformation can effectively improve production efficiency and improve the working environment. For example, for centralized management of furnace groups for large batches of heating furnaces in forging and heat treatment processes, adjustment of heating parameters, control of heating speed, coordination of production rhythm , recording the heating process, etc. are all treated in a unified manner. The original 20 heating equipment requires 5 to 6 people. The traditional method of operations management has been changed to a new production model where a single person can control the entire process. In addition, labor-saving devices (clamping robots, robotic arms) are encouraged at the forging site to reduce the labor intensity of forgers; automatic lubrication devices are used to increase the life of complex shaped molds and are automatically measured to improve; accuracy and efficiency of detection.

Directions for improving the forging model in the future

Automation mode enables equipment automation to eliminate hidden dangers of unstable product quality caused by human operation; Automated on-site production data entry reduces errors and a large amount of repetitive work caused by duplication and manual recording, making it possible to improve production efficiency at the production site. The pace management model combines simplified on-time production management to reduce resource waste on key production equipment, improve production efficiency, and provide support for on-time delivery.

The networked model provides support and information for each process, provides real-time conditions for improvement, direction and space for processes and even external suppliers; provides users with opportunities for improvement and assistance in production process design, quality and other aspects;

The intelligent model reduces redundant management processes, optimizes production processes, and effectively shares and uses data information through intelligence.

The cloud computing model helps accumulate data for manufacturing and compilation of industry standards, and provides early warning of improving quality issues.

The one-piece production model (forging, heat treatment and machining) will become the dominant direction in the future. The one-piece flow production model lays the foundation for the assembly line and also provides support for flexible manufacturing to meet various user needs. The formation of one-piece heating mode will change the current traditional concepts of forging batches and heat treatment batches, and is bound to impact and bring about changes in the industry.

For example, changing the heating method of the current heating furnace should be within the responsibility and patented technology direction proposed by the forging enterprise. The traditional box furnace heating method currently used will be changed in the direction of refined and personalized development. The CAPP system, which adopts front-end process design and programming, can transmit the mode to the one-piece continuous heating furnace through network program control, ensuring that the heating furnace system can automatically open the door of the heating furnace. oven after temperature. and holding time meet the process design requirements, and the forging robot grippers, the forging equipment digitally controls the process parameters (temperature, time, deformation amount, deformation rate, etc.), the heat treatment furnace automatically controls the heat treatment and cooling of the robot clamping operation (oil cooling, water cooling, air cooling) meets the time, precision and accuracy required by the process. All aspects can be achieved.

Changes in quality control models

At present, most of our companies adopt three methods: video surveillance for on-site operations, inspectors for on-site monitoring and inspection, and some monitoring software to collect operational information. These methods are all isolated and separate systems, and there is no such thing. synergy. Therefore, data cannot be predicted and integrated quickly.

Automated equipment (forging equipment and furnaces) can automatically collect relevant information, including temperature monitoring and deformation monitoring. In big data statistical mode, historical data can be compared and analyzed in real time, and trend analysis of product quality data can be formed. . Provide a basis for correcting errors on site in real time, improving quality and consolidating process results. Hongyuan Company has initially implemented a centralized furnace cluster monitoring system model, but there is still much room for improvement.

Currently, dimensional monitoring of thermoforming is a technical difficulty. It is reported that Tsinghua University already has high temperature measurement technology reserves in this field, which can be used to develop corresponding monitoring and measurement tools. Measuring low, medium and high temperatures is also a technical difficulty at present. Fluke bought the patent of a light tube company in the United States and can produce handheld or online infrared temperature measuring equipment. Hongyuan Company purchased two customized portable temperature measuring devices. equipment. .

There are complete sets of mature equipment and technologies for cold dimensional line measurement, automatic measurement and wireless (wired) measurement special tools, but they are rarely used in the machining process of the forging industry.

The application of monitoring methods and technologies within the framework of the above new model can be integrated into the enterprise management system, gradually withdrawing paper files and records from the historical stage and forming electronic records for future authorized access, statistical analysis, technological improvement and application expansion. . Provide a foundation.

fundamental research

As a heavy forging enterprise in China, we must lead the development of forging industry and heat treatment industry. However, our current foundation is still relatively weak, and the degree of integration of industrialization and informatization is low. unable to shoulder the heavy responsibilities of the country and the group and adapt to the development of key models in the future.

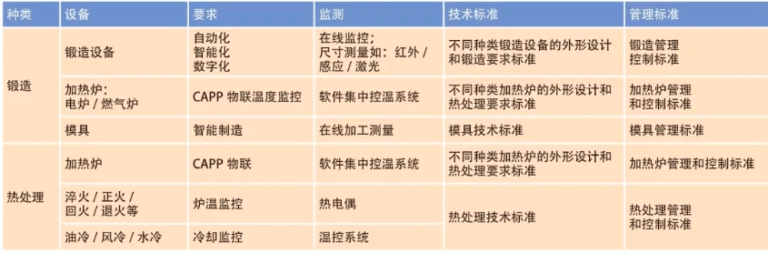

At present, it is necessary to start basic research work focusing on the forging industry to form process technology, equipment (forging, heating furnace), measurement (monitoring and hot dimensional measurement and cold) and management (such as batch management) centered on forging and heat treatment, materials, standards and other systematic planning to form an industrial and patent authority, control and direct all related upstream and downstream enterprises forging and replace the current model of passively accepting user design requirements to produce forgings. is presented in Table 1.

Table 1 Basic Research Worksheet for the Forging Industry

The above can be extended to a family of technical standards and a family of management standards based on different equipment and different types of materials. We can also check and fill gaps against current standard systems such as GB, GJB, ASTM and. FR and draft standards with independent patented technologies to provide companies with impetus for future development.

Building a talented team

Judging from the future development requirements of the enterprise, the backbone of true competitiveness of the enterprise is high-quality and competent personnel. Currently, the company does not have a systematic expert team, at least not an influential expert team in the industry. Creating and training a team of experts cannot be done overnight. It takes time and experience, but also recognition within the industry. The team of experts that we form is not only known within the heavy machinery subsidiaries, but must also be known in the aviation industry and nationally. The expert team should not only consist of technical and quality experts, but should systematically plan and train a team of management experts in all aspects, such as Lean experts, AOS experts and experts in computerization, and promote and improve the corporate image of the company and even the industry through expert business cards.

Conclusion

At present, the aviation forging industry is experiencing problems such as extensive management model, insufficient industrial innovation, poor energy utilization, insufficient computerization level, and poor quality and efficiency. mediocre. It is far from the national requirements of “Made in China 2025”. At present, intelligent equipment and automated information technology are widely used, and there is no problem with future applications in the forging industry. Intelligent manufacturing in the aerospace forging industry is achievable. In the future, national defense equipment, aviation equipment, etc. will have higher and higher technical requirements for forged products, which gives us motivation and source for our own improvement. At the same time, we can also use technological transformation and national defense. other projects to update and transform.

Industry 4.0 manufacturing requirements have become popular and have also promoted the development of various industries. If we do not make progress in the application of 5G Internet of Things technology, we will not be able to achieve it in the future. computerization and intelligent linking of activities and management with OEM manufacturers and engine factories.

Networked cloud computing has been used in many industries and fields, providing early warning of product quality and business operations, providing cloud data support for equipment construction, and ensuring the development of Big Platforms. Data for industry.

Aerosmithing practitioners must emancipate their minds and continually innovate thinking patterns, management models, etc. in order to comply with national strategic development requirements.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.